A three-dimensional automatic welding system and its welding control method

An automatic welding and three-dimensional technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of low welding efficiency and high labor intensity of workers, and achieve the effects of stable operation, reduced capital investment, and low-noise operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

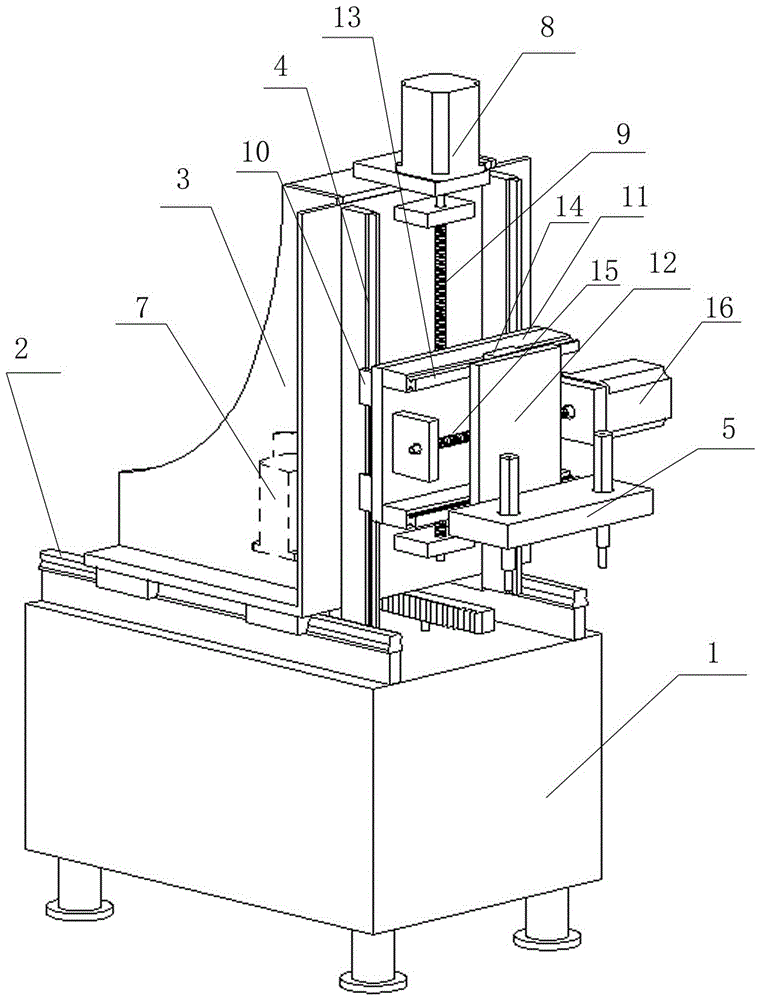

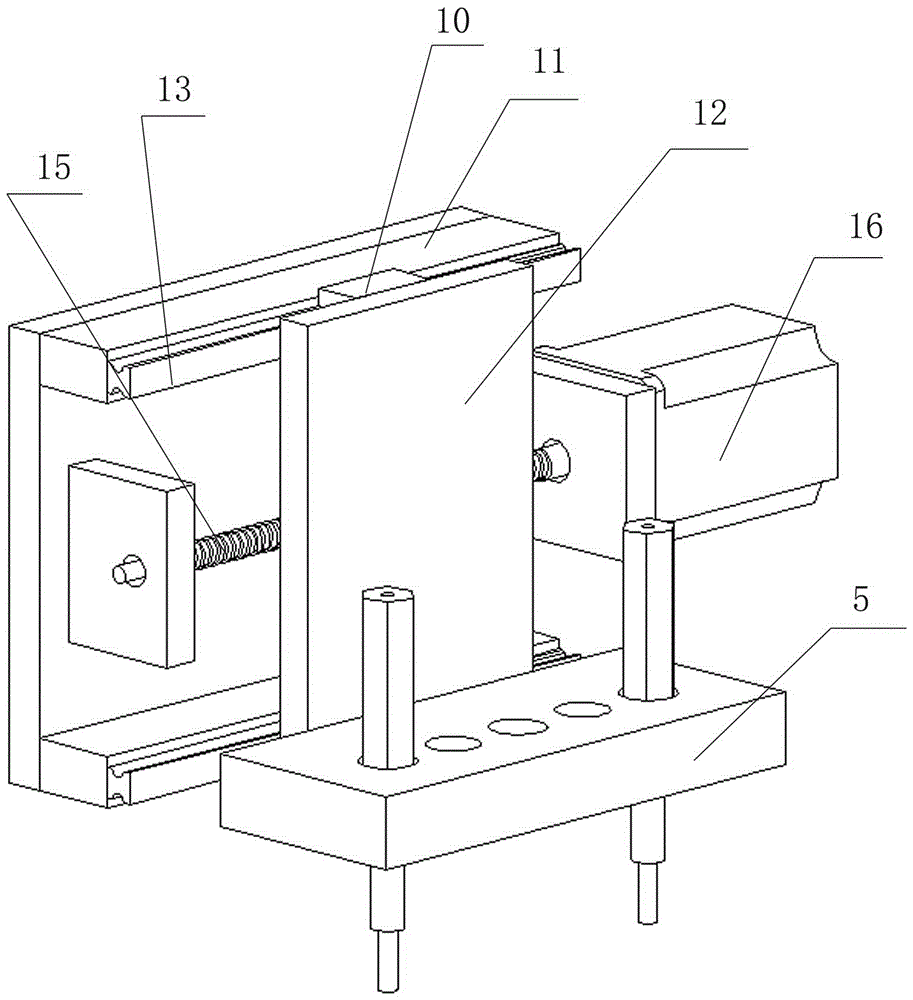

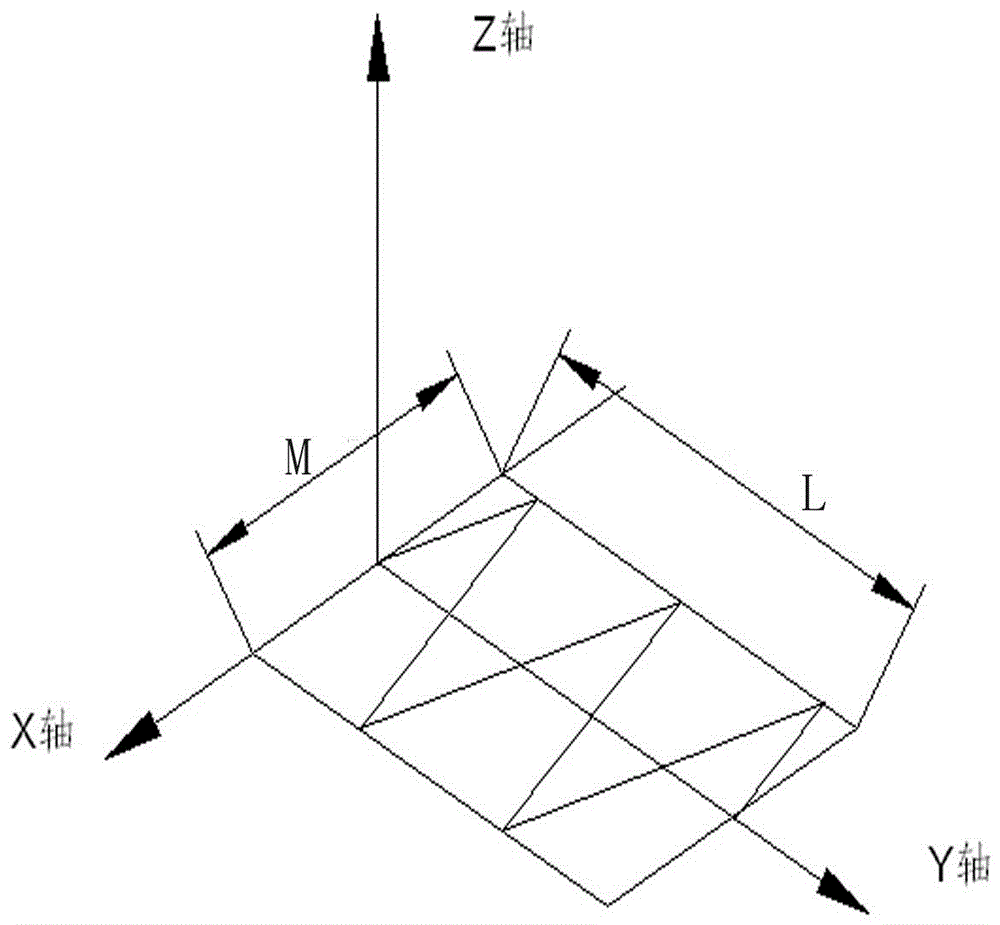

[0030] exist figure 1 and figure 2 Among them, the present invention provides a three-dimensional automatic welding system, which mainly includes a welding torch operating mechanism, a control cabinet 21, a welding machine and a wire feeder, the welding machine is set as a gas shielded manual welding machine, and the welding torch operating mechanism includes a swing Mechanism, lifting drive mechanism, straight-running mechanism and base (1), the moving directions of the swinging mechanism, the moving direction of the lifting driving mechanism and the moving direction of the straight-running mechanism respectively correspond to the X-axis direction, Z-axis direction and Y-axis direction of the three-dimensional rectangular coordinate axis , the straight-travel mechanism is located on the upper part of the base 1, and a straight-travel drive device is provided on the straight-travel mechanism. The side of the bracket 3 provided by the mechanism is provided with a lifting driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com