Tool special for overlaying and assembly welding of small-caliber elbows and installing method

A small-diameter, elbow technology, applied in the field of special tooling and installation for small-diameter elbow surfacing and assembly welding, can solve the problems of special product structure, inability to guarantee surfacing welding quality, and variable welding positions, and achieve a simple design structure. , Solve the problem of welding weight and the effect of short manufacturing cycle

Active Publication Date: 2015-03-11

HARBIN BOILER

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a special tooling and installation method for surfacing and assembly welding of small-diameter elbows, which solves the problem that the welding position during manual surfacing welding is variable and the quality of surfacing welding cannot be guaranteed due to the special structure of the product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

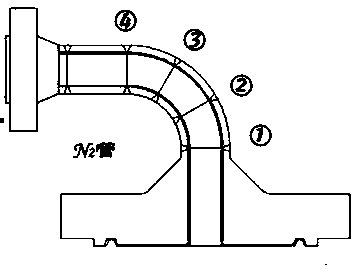

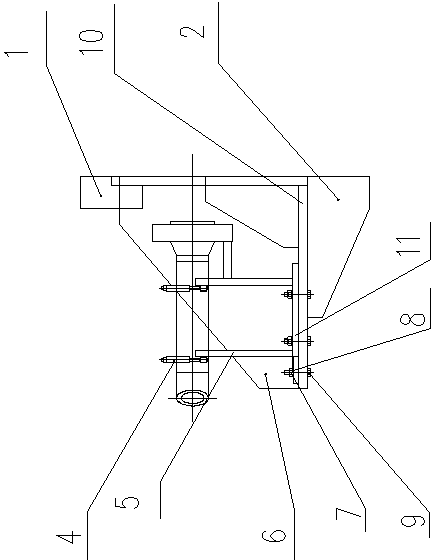

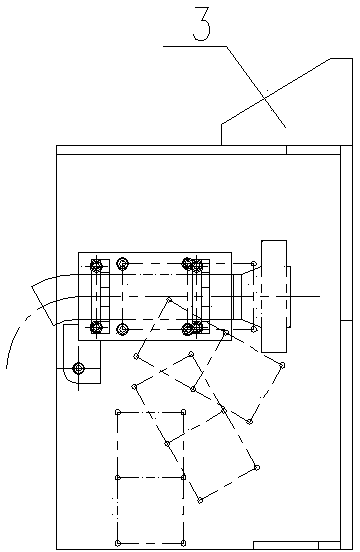

Provided are a tool special for overlaying and assembly welding of small-caliber elbows and an installing method. At present, the elbows are manufactured by means of a traditional manufacturing process 'trisection-respective overlaying-assembly welding and overlaying', and the traditional manufacturing process is still widely adopted, has the advantages of being simple in required devices and low in manufacturing cost and has the shortcomings of being complicated and tedious in process, long in manufacturing period and large in manual overlapping work amount. The tool special for overlaying and assembly welding of the small-caliber elbows comprises a small rib plate(1), wherein the small rib plate is connected with a bent plate (6), the bent plate is connected with a large rib plate (2), a middle rib plate (3) and a base plate (10) respectively, the base plate is connected with a support fixing plate (11), the support fixing plate is connected with a bolt (7), a nut (9), a washer (8) and a large support (5), the large support is connected with a small support, and an upper seal head elbow module and a lower seal head elbow module are installed on the small support. The tool is mainly applied to overlaying and assembly welding of the small-caliber elbows and the installing method.

Description

Technical field: The invention relates to a small-diameter elbow special tooling for surfacing and assembly welding and an installation method. Background technique: At present, there are three forming methods and manufacturing problems for small-diameter elbow parts. The traditional manufacturing process of "three equal parts-respective welding-reassembly and welding" is adopted. This process method is still widely used today. The advantage is that the required equipment is simple and the manufacturing cost is low. The disadvantage is that the process is complex and cumbersome, the manufacturing cycle is long, and the workload of manual surfacing is large; The small-diameter elbow is a research and development bending process, that is, the straight pipe is first surfacing and then bent into a 90° elbow, that is, "welding first and then bending". The advantage is that the equipment required for the manufacturing process is simple, and the disadvantage is that the forming pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K37/047

CPCB23K9/044B23K37/047

Inventor 马鸣张盛岩张亚奇李春光欧海燕

Owner HARBIN BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com