Processing process of fixing rod

A processing technology and technology for fixing rods, which is applied in the processing technology field of fixing rods, can solve problems such as unfavorable, insufficient precision of fixing rod holes, and non-conformity of the overall shape of the fixing rods, so as to improve precision, reduce defective rate, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

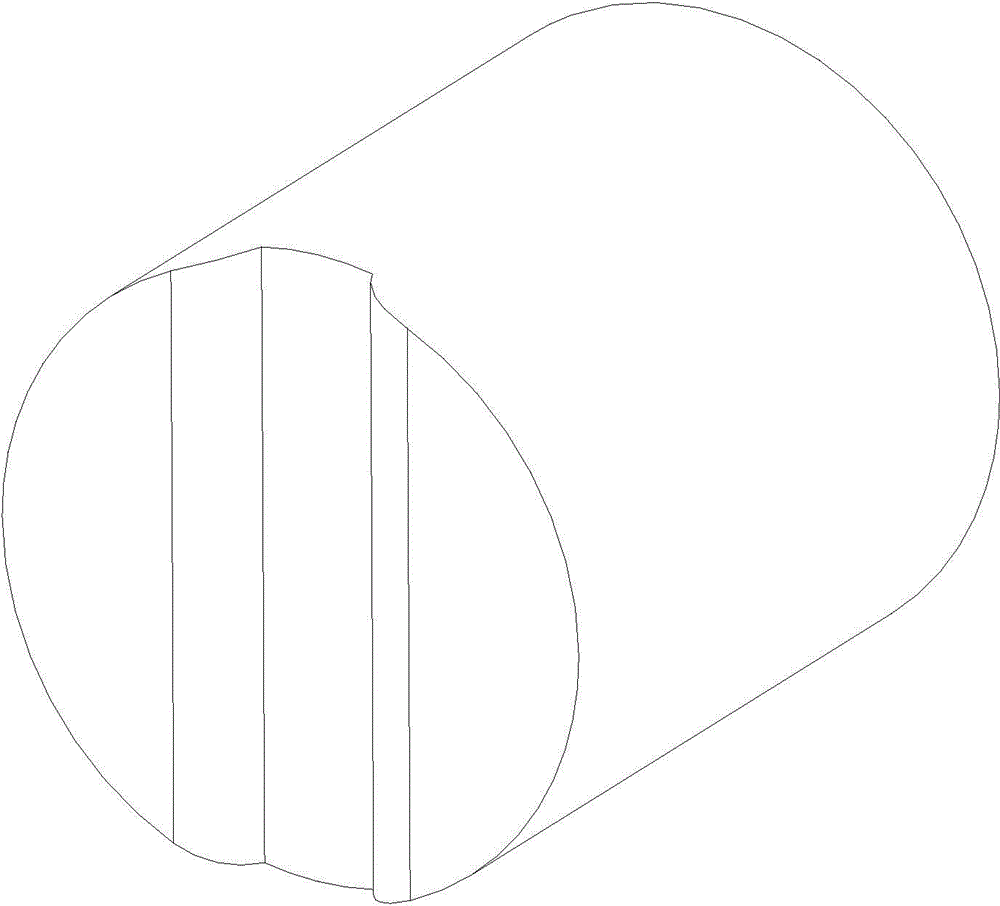

[0013] Embodiment two: the first step: cut the material with a machine tool, process the profile of the fixed rod according to the drawing size, the diameter of the fixed rod is φ26mm, and determine the diameter of the fixed rod; the second step: use the machine tool to process the fixed rod The rod is reversely cut to a length of 30mm, and the length of the fixed rod is determined; the third step: use a milling machine to mill the groove, and center the center of the fixed rod on the φ26mm end face of the fixed rod, mill a groove with a width of 5mm and a depth of 2mm, according to the requirements of the drawing Groove milling; step 4: chamfering the two ends of the fixed rod, chamfer R3; step 5: stress treatment, stress treatment on the fixed rod; step 6: polishing the finished product, the surface is rough Degree Ra12.5; Step 7: Inspection and warehousing of products, random inspection of appearance and size, 10 samples for appearance and 6 samples for size.

Embodiment 3

[0014] Embodiment three: the first step: cut the material with a machine tool, process the shape of the fixed rod according to the size of the drawing, the diameter of the fixed rod is φ26.1mm, and determine the diameter of the fixed rod; the second step: process it out with a machine tool The fixed rod is reversely cut to a length of 30.2mm, and the length of the fixed rod is determined; the third step: use a milling machine to mill the groove, and mill a groove with a width of 5.1 and a depth of 2 on the end face of the fixed rod with a diameter of 26.1mm centered on the center of the fixed rod. , carry out milling processing according to the requirements of the drawings; the fourth step: chamfer the two ends of the fixed rod, chamfer R3; the fifth step: carry out stress treatment, and carry out stress treatment on the fixed rod; The surface is polished, and the surface roughness is Ra12.5; Step 7: Inspection and storage of the product, random inspection of appearance and siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com