Concrete mixing transportation truck raceway

A technology for mixing trucks and concrete, applied in the field of machinery, can solve the problems of large welding heat, welding can skin, large elastic deformation, etc., to improve the strength and rigidity of the tank, reduce the welding seam opening, and improve the bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

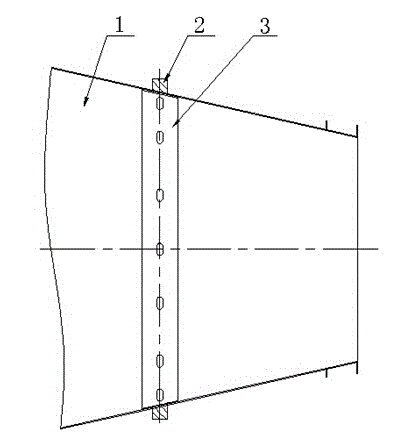

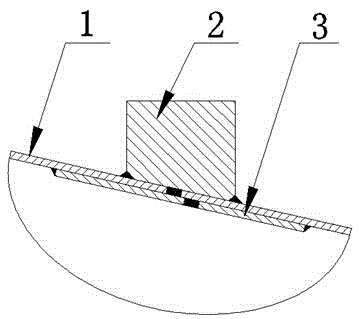

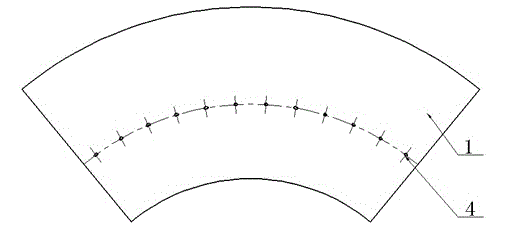

[0017] like Figure 1-Figure 4 As shown, the raceway 2 of the concrete mixer truck is connected to the outer wall of the rear cone 1 of the mixer truck body, and the reinforcement plate 3 is connected to the inner wall of the rear cone 1 of the mixer truck body; the reinforcement plate 3 is cut by a CNC plasma cutting machine Fan-shaped plate; the rear cone of the tank corresponding to the raceway 2 is provided with an oblong hole I4, the oblong hole I4 of the tank rear cone is set to 30x60mm, and the hole spacing is 400mm; the reinforcement plate is provided with an oblong hole II5, the The reinforcement plate oblong hole II5 is set to 30x60mm, and the hole spacing is 595mm.

[0018] The reinforcement plate 3 has a width of more than 180 mm and a thickness of 1 to 1.2 times the thickness of the tank body. Both sides of the reinforcement plate 3 are intermittently welded to the inner surface of the rear cone of the tank body, and the oblong hole I4 is connected to the inner su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com