Label absorbing device of system for internally labeling injection mold

A technology of injection molding and labeling, applied in the direction of coating, etc., can solve the problems of label drop, product qualification rate reduction, label paper can not be attached, etc., to reduce manufacturing costs, improve production efficiency, improve the effect of qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

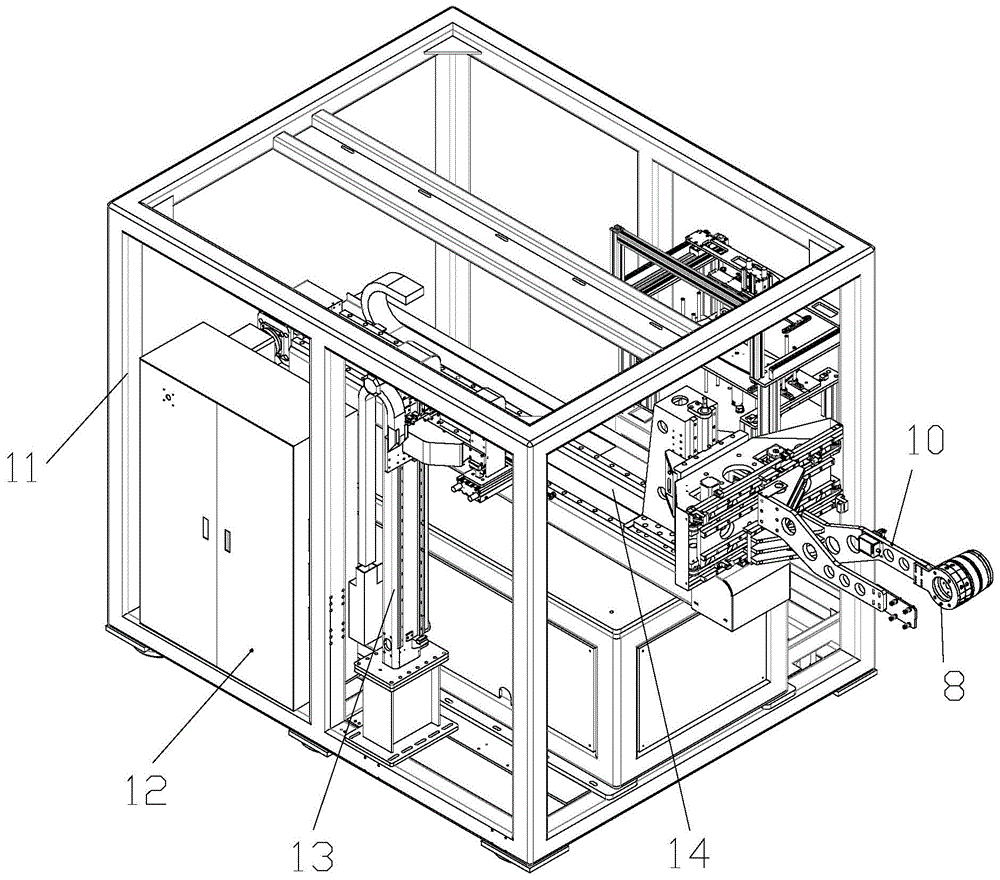

[0016] see figure 1 , the label suction device of the injection molding in-mold labeling system of the present invention, the in-mold labeling system is matched with the injection molding machine and includes a labeling cabinet 11, a control cabinet 12 and a Z-axis guide rail 13 installed in the labeling cabinet 11, and is installed on the The Y-axis guide rail 14 on the upper Z-axis guide rail 13 and the labeling robot arm 10 installed on the Y-axis guide rail 14;

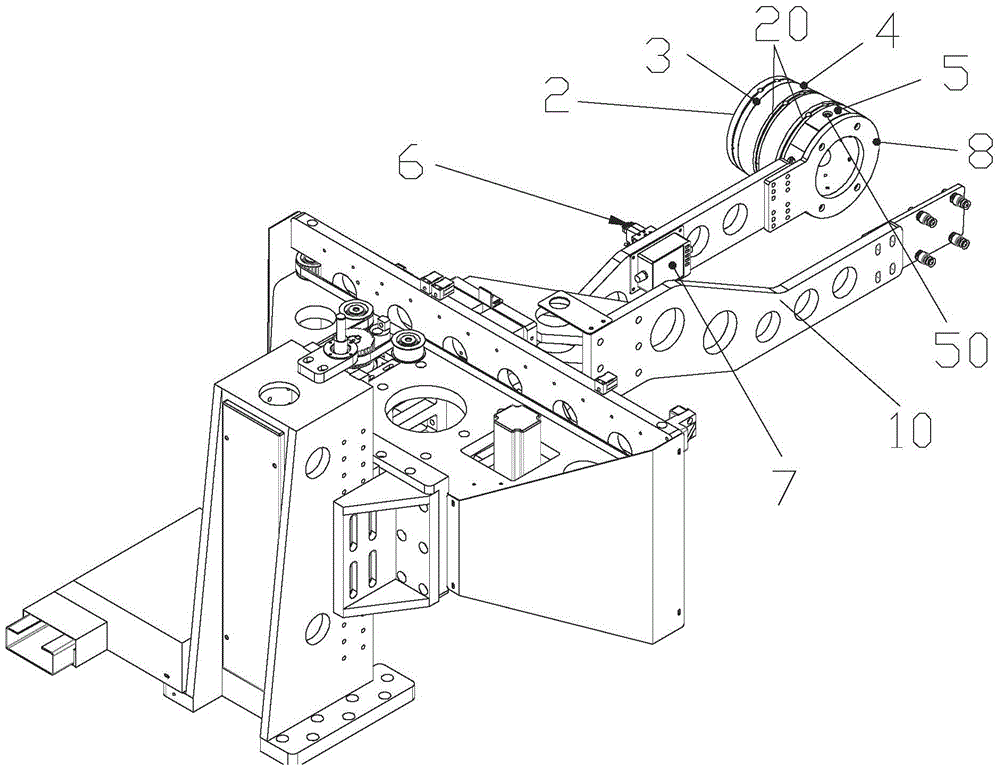

[0017] The label suction device is installed on the labeling robot arm 10, and the label suction device includes a label suction fixture 2, an electrostatic needle 3, an electrostatic sponge 4, a movable stopper 5, a compression spring, a vacuum generator 6, and an electrostatic generator 7, wherein:

[0018] The label suction fixture 2 is cylindrical and two ventilation grooves 20 communicated with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com