Automobile glass heating method and heating device thereof

A technology of automobile glass and heating method, applied in the field of heating of automobile glass and heating device of automobile glass, can solve the problems of space channeling temperature of heating furnace, control of unfavorable convection heating, reduction of utilization rate, etc., to ensure stability and heating The effect is uniform and stable, and the effect of high energy consumption is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The content of the present invention will be further described below in conjunction with the accompanying drawings.

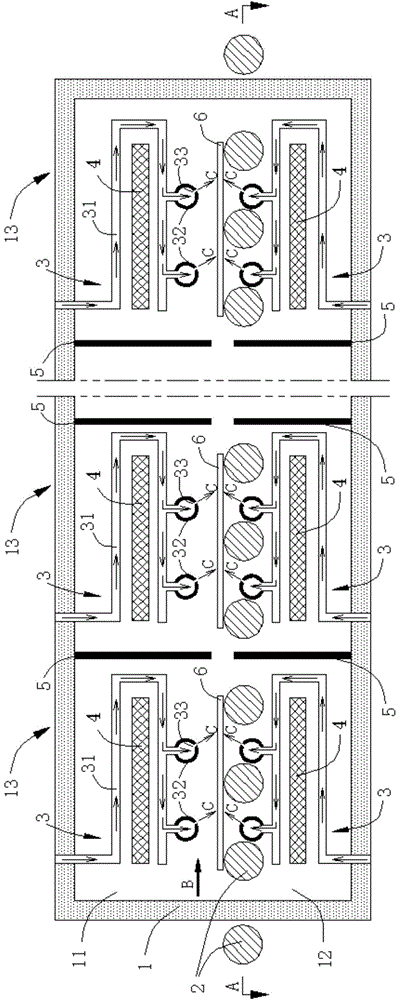

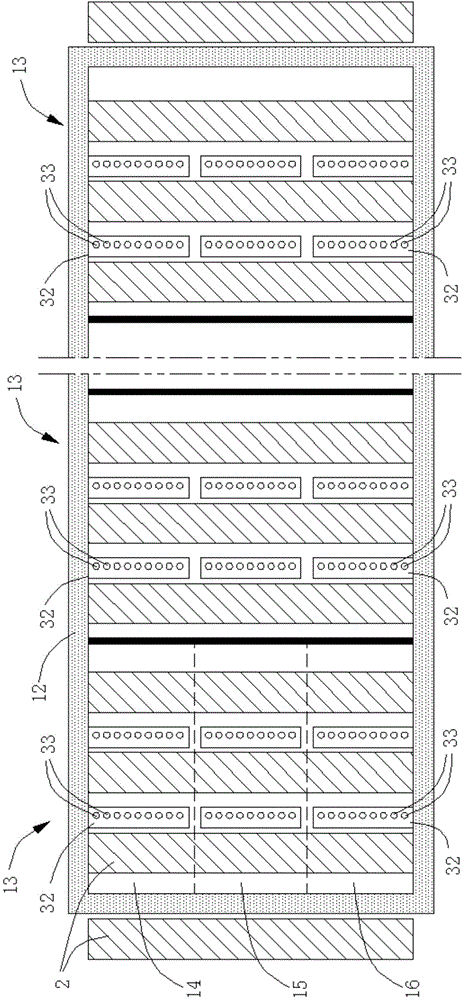

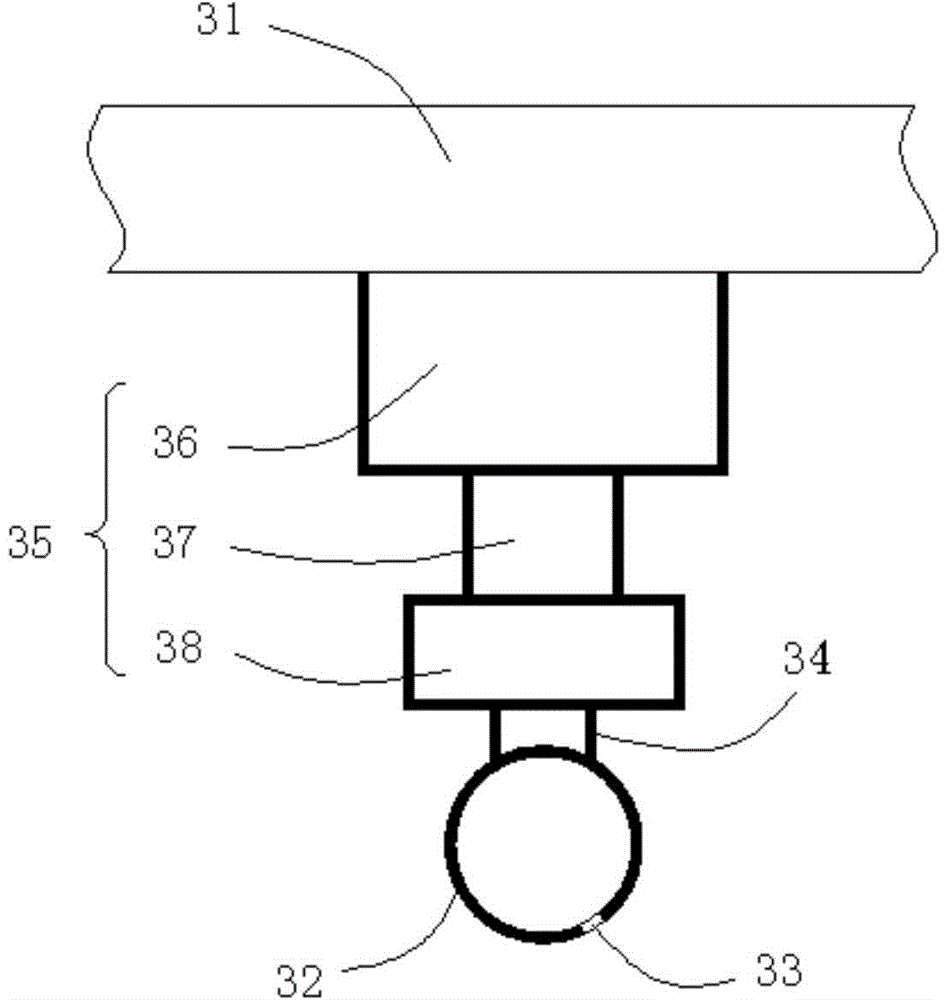

[0044] like Figure 1 to Figure 2 As shown, a method for heating automotive glass according to the present invention is used for heating coated glass and non-coated glass alternately loaded on the conveying roller 2, and the coated glass and non-coated glass are used to be paired together to form an interlayer Glass, the coated glass and non-coated glass are transported into the heating furnace 1 on the transmission roller 2 and passed out of the heating furnace 1 after being heated to a set temperature, and the heating furnace 1 has a transmission direction with the transmission roller 2 B parallel to the length direction and the width direction parallel to the axial direction of the conveying roller 2, the heating furnace 1 includes a furnace body upper part 11 and a furnace body lower part 12, and the heating furnace 1 passes through the furnace body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com