A kind of injection type conductive asphalt concrete, bridge deck pavement structure and pavement method

A technology of conductive asphalt and bridge deck pavement, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of block electricity being easily crushed, unfavorable to the safety of vehicles and pedestrians, and loss of function, so as to prevent short circuits and ineffective Safety, uniform and stable heating effect, and the effect of alleviating low temperature cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

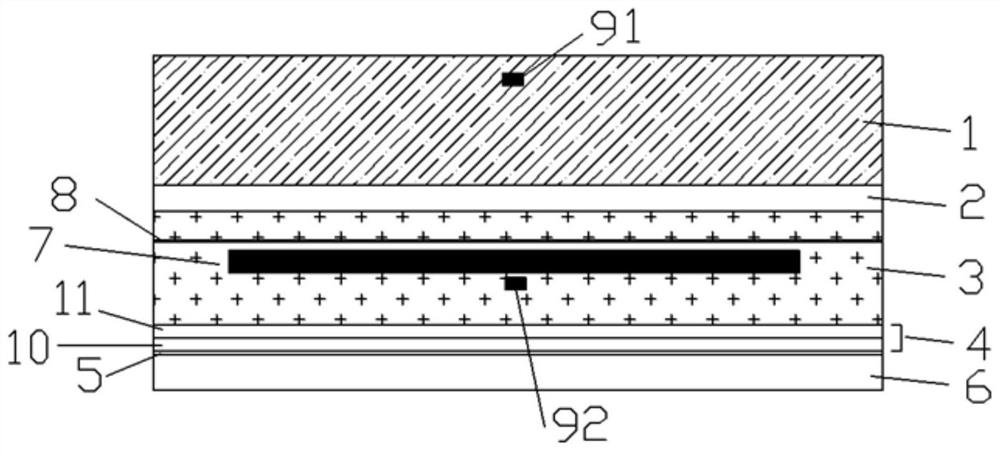

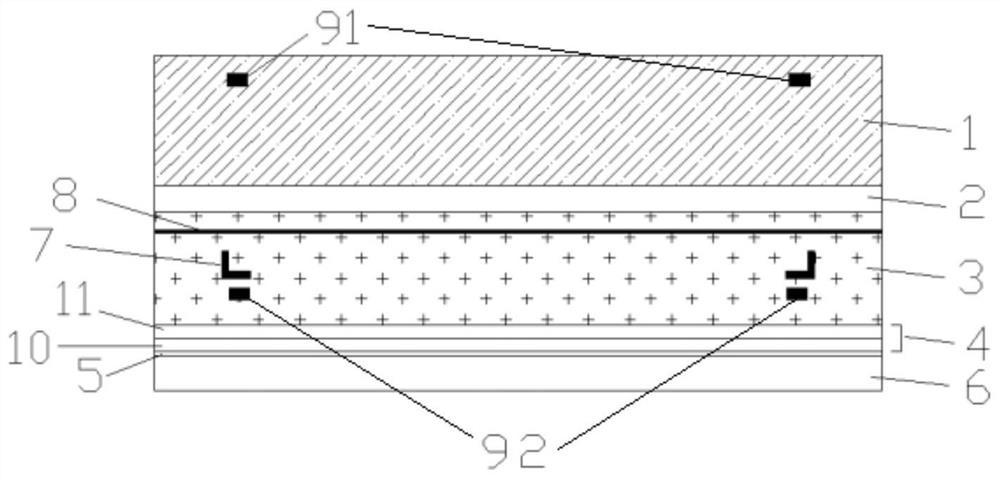

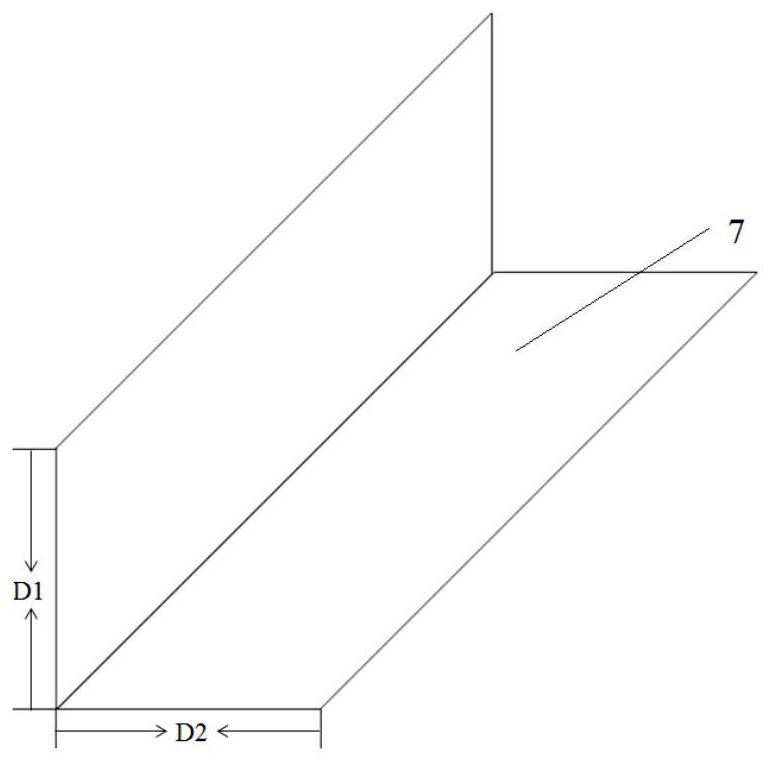

[0052] Comply with the above technical solutions, such as figure 1 As shown, this embodiment provides a pouring conductive asphalt concrete steel bridge deck pavement structure, including asphalt mastic macadam concrete layer 1, adhesive layer 2, pouring conductive asphalt concrete layer arranged in sequence from top to bottom 3. Waterproof heat insulation layer 4, anti-corrosion layer 5 and steel bridge deck 6, first temperature sensor 91 is set in asphalt mastic macadam concrete layer 1; The material spreading layer 8, two opposite electrodes 7 and the second temperature sensor 92, the waterproof and heat-insulating layer 4 includes a bottom-up double-layer epoxy resin waterproof layer 10 and a 4mm rubber asphalt mastic buffer layer 11.

[0053] The pourable conductive asphalt concrete adopts 35mmGCA, the asphalt used is composite modified asphalt, and the asphalt ratio is 9.75%. The coarse aggregate used is high-quality basalt, the fine aggregate is limestone machine-made ...

Embodiment 2

[0071] This embodiment provides a pouring conductive asphalt concrete steel bridge deck pavement structure. Compared with the pouring conductive asphalt concrete steel bridge deck pavement structure in Example 1, the only difference is that in this embodiment, the pouring conductive asphalt concrete steel bridge deck pavement structure is The asphalt concrete layer used in the asphalt concrete layer 3 has an asphalt ratio of 9%, SBS type modified asphalt: natural lake asphalt: viscosity reducer = 70:25:1.5, carbon fiber content is 0.6%, carbon fiber spreading layer spreading amount 110g / m 2 .

Embodiment 3

[0073]This embodiment provides a pouring conductive asphalt concrete steel bridge deck pavement structure. Compared with the pouring conductive asphalt concrete steel bridge deck pavement structure in Example 1, the only difference is that in this embodiment, the pouring conductive asphalt concrete steel bridge deck pavement structure is The asphalt ratio of the castable conductive asphalt concrete used in the asphalt concrete layer 3 is 9.5%, SBS type modified asphalt: natural lake asphalt: viscosity reducer = 72:22:1.6, carbon fiber content is 0.7%, carbon fiber spreading layer spreading amount 230g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com