Sewing and embroidering machine

A sewing embroidery machine and sewing embroidery technology, applied in the field of sewing embroidery machines, can solve the problems of affecting the installation of the embroidery mechanism, unable to meet the supply demand, occupying a large space, etc., and achieve the effects of simple structure, easy tensioning and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

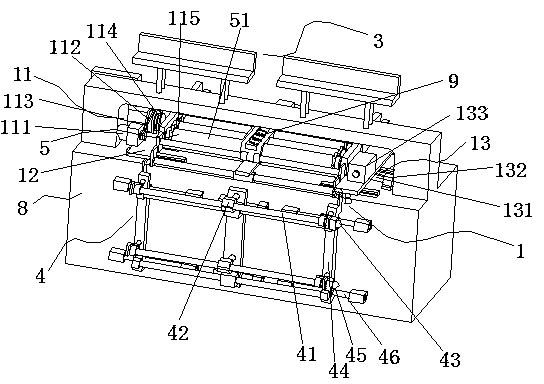

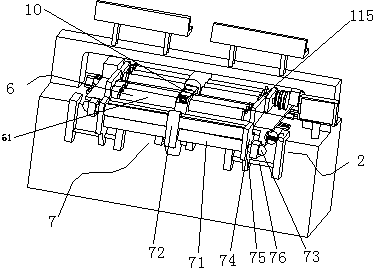

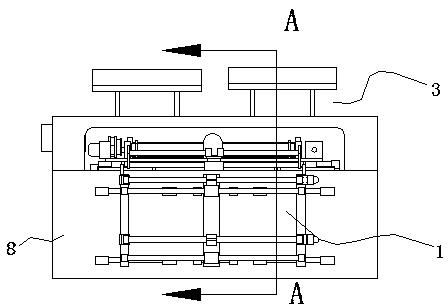

[0038] Such as Figure 1-4 Shown, as an embodiment of the present invention, a kind of sewing and embroidery machine comprises frame 8 and sewing and embroidery unit, and described sewing and embroidery unit comprises feeding mechanism 1, discharging mechanism 2 and is arranged on feeding mechanism 1, discharging. The sewing and embroidery mechanism 3 between the mechanisms 2, the feeding mechanism 1 includes the feeding support device 4 and the feeding guide device 5 for carrying the cloth, and the discharge mechanism 2 includes the discharging guide device 6 and the cloth carrying device The output supporting device 7 has at least two sewing and embroidery units. In this embodiment, there are two sewing and embroidery units. According to the needs of embroidery, it can be set to three or more sewing and embroidery units. The two sewing and embroidery units are arranged side by side on the frame 8, and the feeding guide devices 5 of the two adjacent sewing and embroidery unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com