Jacking support system and jacking support method

A support system and support method technology, applied in the direction of pillars, erecting/assembling bridges, bridges, etc., can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

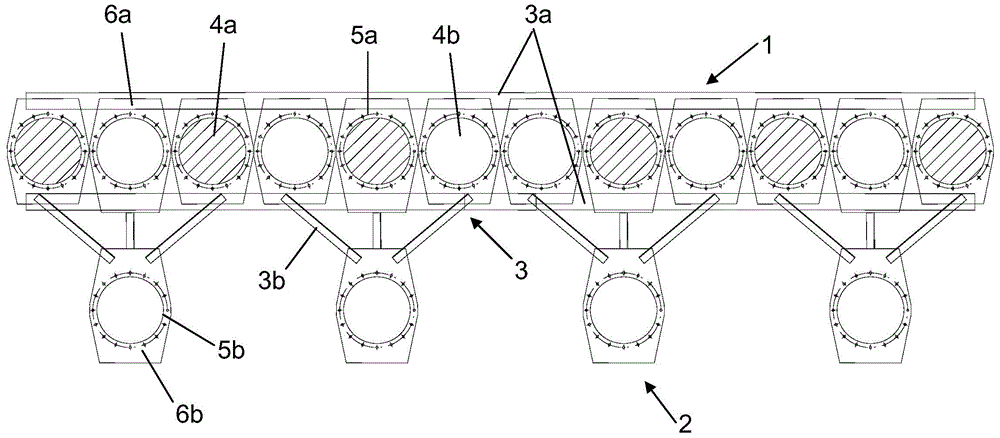

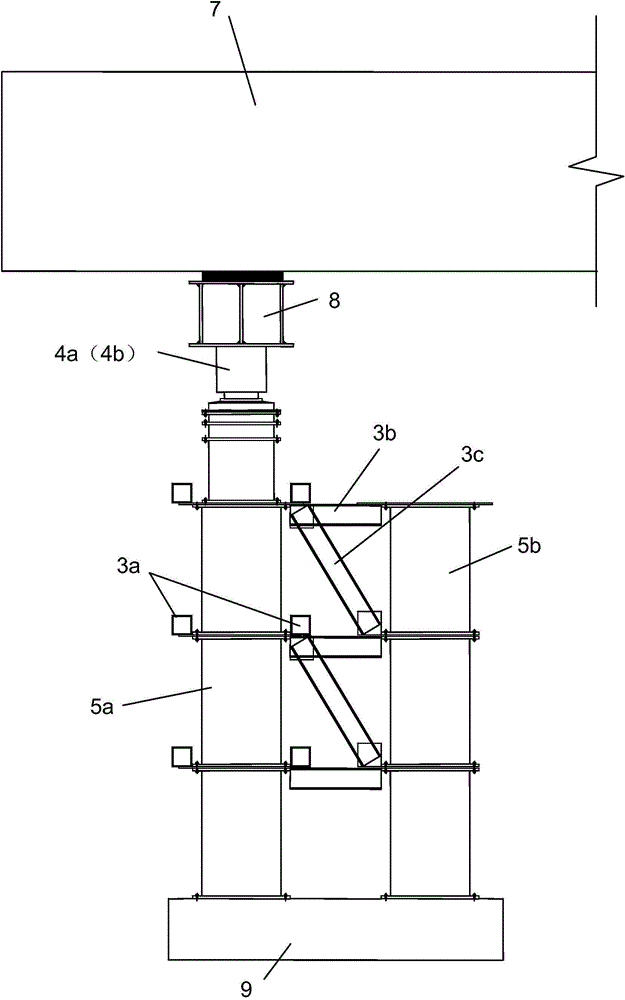

[0025] see Figure 1 ~ Figure 2 As shown, the jacking support system of the present invention mainly includes a group of jacking steel supports 1, a group of stable steel supports 2, and a connection between the jacking steel supports 1, the jacking steel supports 1 and the stabilizing steel supports 2. Between and form an integrated steel lattice structure 3. Wherein, the jacking steel supports 1 are arranged on the lower parts of the pistons of the jacks 4a and 4b respectively, and each jacking steel support 1 includes several steel cylinders 5a stacked one after another in the longitudinal direction, and the two steel cylinders adjacent to each other vertically Flange plates 6a are arranged between the 5a and fixed by bolts; the stable steel supports 2 are respectively arranged on one side of the jack 4, and each stable st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com