Polishing composition and polishing method

A composition and compound technology, used in polishing compositions containing abrasives, grinding devices, grinding machine tools, etc., can solve the problems of inability to control the concentration of oxidants, difficulty in grinding control, corrosion of metal wiring grinding devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

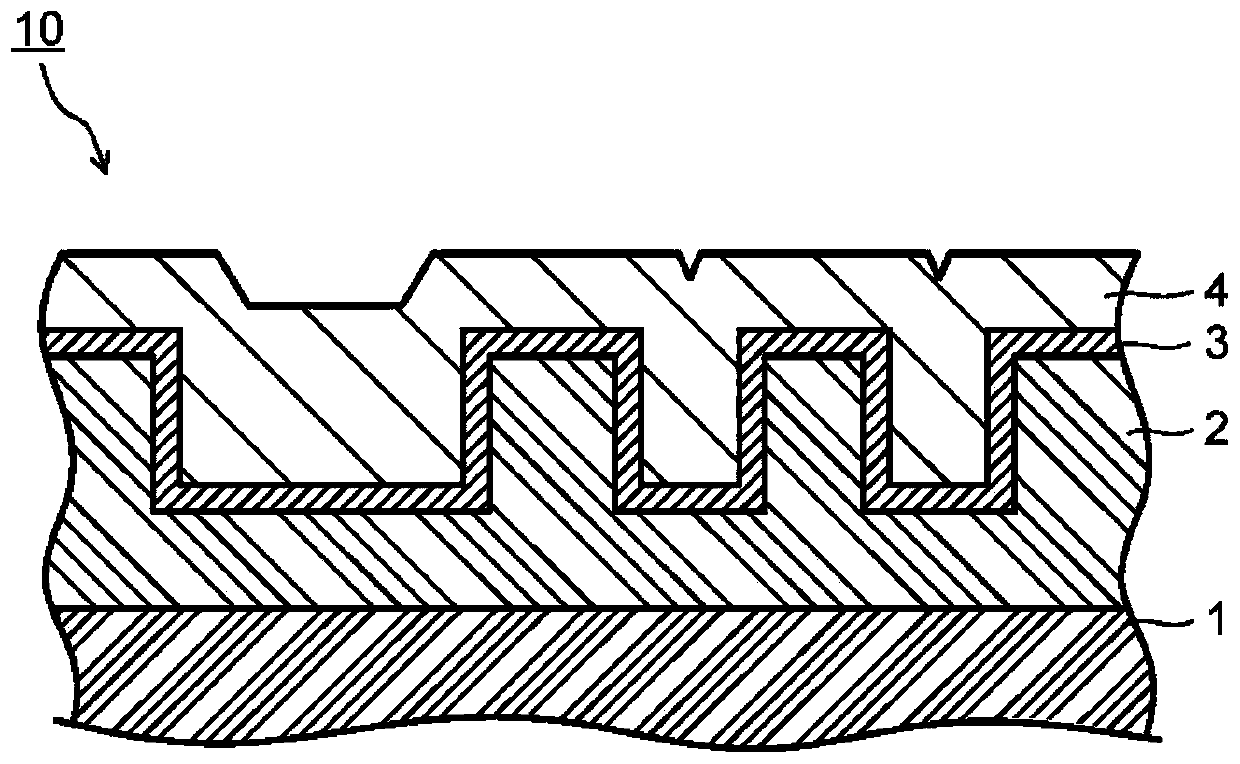

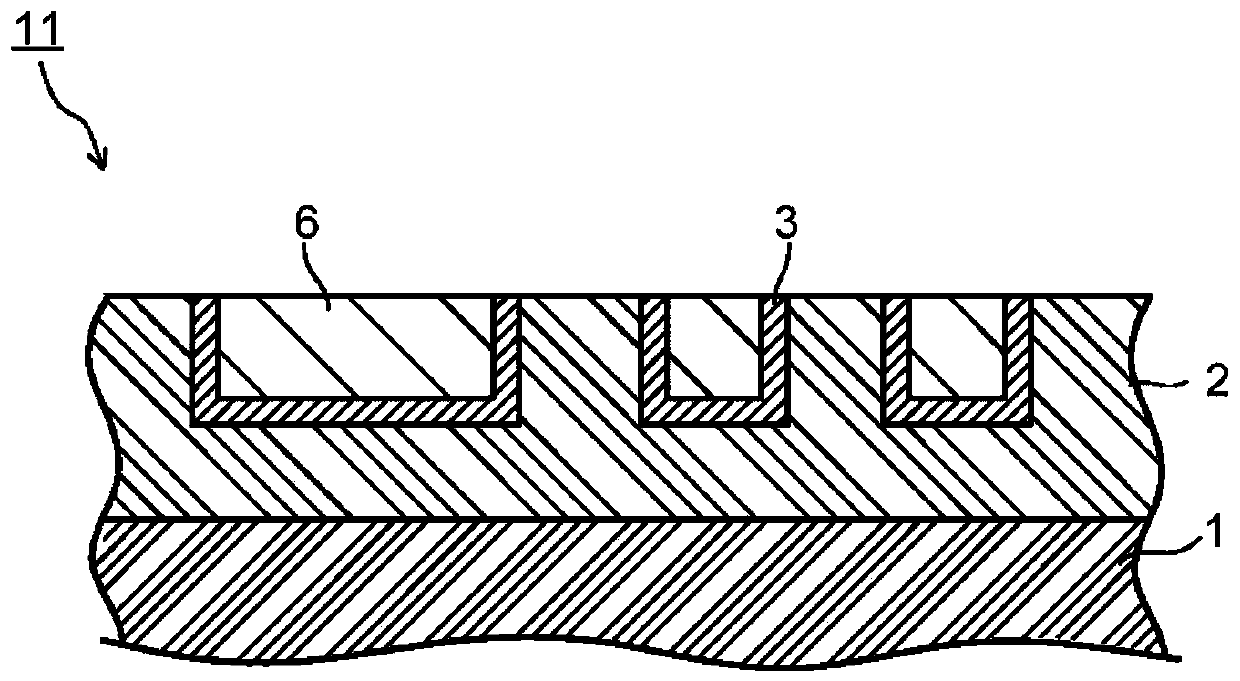

Image

Examples

preparation example Construction

[0132]

[0133] In order to prepare this polishing composition, compound (1) and cerium oxide particles are added as essential components to a liquid medium containing water such as pure water and ion-exchanged water, and further, if necessary, a rust inhibitor and the like are added as optional components and carried out. Just mix it. At this time, a pH adjuster may be added as needed, and it may prepare so that the pH of the obtained polishing composition may fall within the said preferable range. In order to contain cerium oxide and other abrasive grains in the present polishing composition, a method of adding and mixing the above-mentioned components to a dispersion liquid in which the abrasive grains are dispersed is used. After mixing, stirring is performed for a predetermined time using a stirrer or the like to obtain a uniform polishing composition. In addition, a better dispersion state can also be obtained by using an ultrasonic disperser after mixing.

[0134] T...

Embodiment

[0150] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, this invention is not limited to these Examples.

[0151] Examples 1-11 are examples, and Examples 12-13 are comparative examples. In the following examples, "%" means mass % unless otherwise specified. In addition, the characteristic value was measured and evaluated by the following method.

[0152] [pH]

[0153] About pH, it measured using the pH meter HM-30R by DKK-TOA CORPORATION.

[0154] [Average secondary particle size]

[0155] The average secondary particle diameter was measured using a laser scattering / diffraction particle size distribution analyzer (manufactured by HORIBA, Ltd., device name: LA-920).

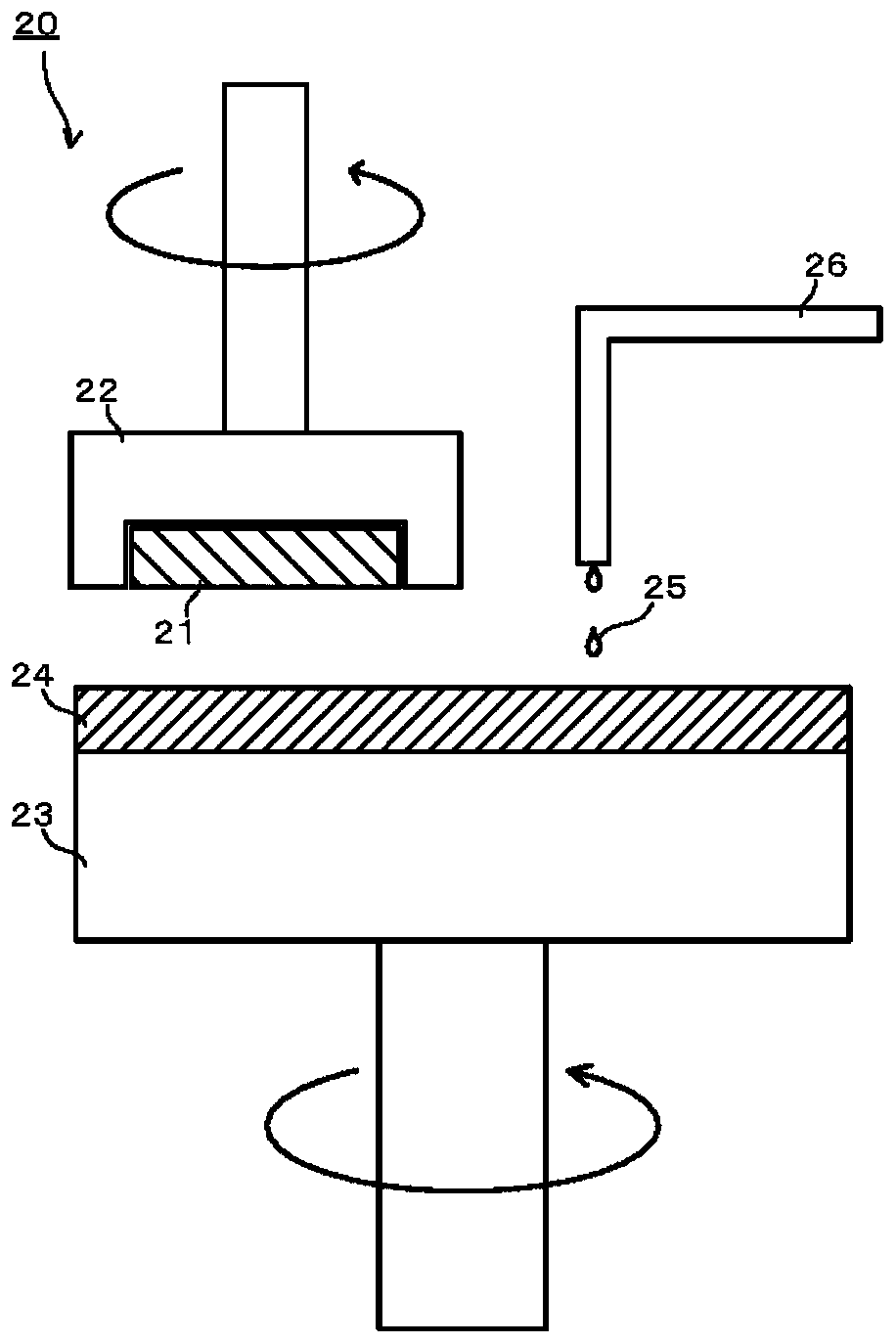

[0156] [Grinding characteristics]

[0157] The polishing characteristics were evaluated by performing the following polishing using a fully automatic CMP polishing apparatus (manufactured by Applied Materials, apparatus name: Mirra). A foamed hard polyur...

example 1

[0163] Pure water, compound (1Si-1)·K +, polyacrylic acid, and a pH adjuster are mixed to prepare a mixed solution adjusted so as to become a predetermined pH, and the mixed solution is added to disperse cerium oxide particles with an average primary particle diameter of 60 nm (average secondary particle diameter of 90 nm). The mixture was mixed with a cerium oxide dispersion liquid made of pure water to obtain a polishing composition (1) having a pH of 9.0. Table 3 shows the content of each component in the polishing composition (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com