Mildew-proof color paste and preparation method thereof

A color paste and anti-mildew technology, applied in the direction of pigment paste, etc., can solve the problems of single product performance, high biological toxicity, complex materials, etc., to improve safety performance, reduce toxic gases, increase wettability and dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

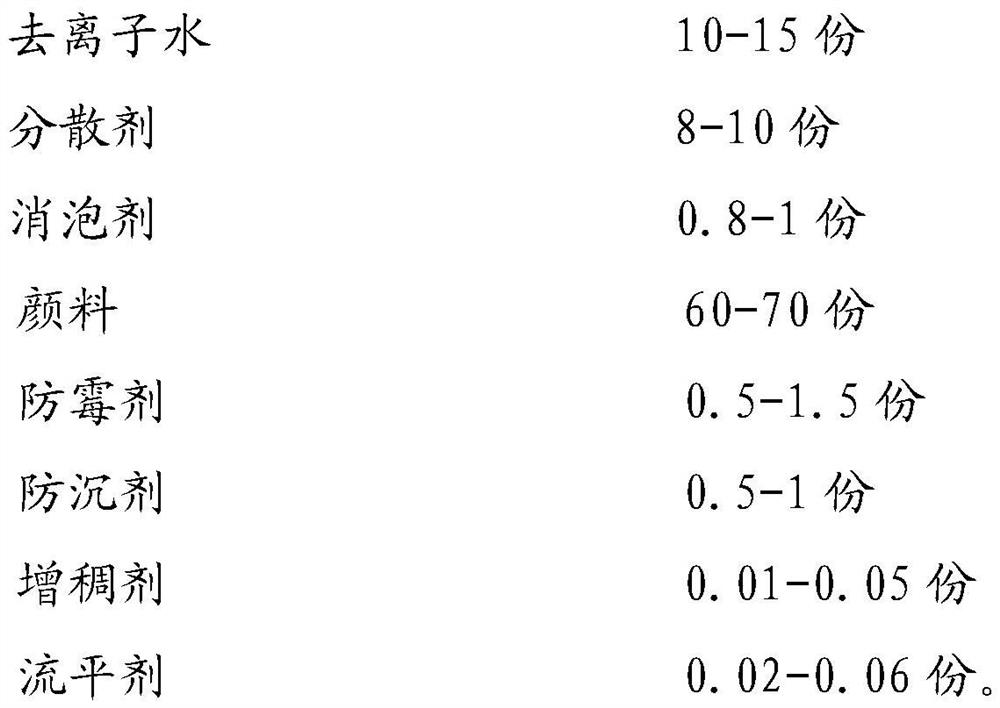

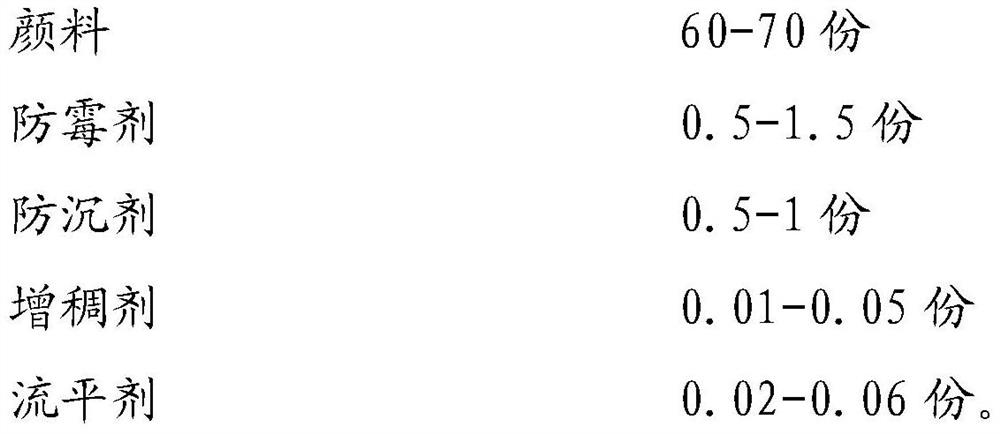

[0034] Anti-mildew color paste of the present invention comprises the following components by weight:

[0035] 12 parts of deionized water, 9 parts of dispersant, 1 part of defoamer, 60 parts of titanium dioxide, 1.5 parts of antifungal agent, 1 part of anti-settling agent, 0.05 part of thickener and 0.06 part of leveling agent

[0036] Among them, the deionized water is tertiary water; the dispersant is polyacrylic acid sodium salt, which is the P30 of Gaotai in France; the defoamer is A10 of Corning; The thickener is any one of hydroxyethyl cellulose or alkali-swellable thickener; the alkali-swellable thickener can be selected from ASE60 of Oriental Tomorrow Chemical Co., Ltd.; the leveling agent is a solvent-free polyurethane fluid The leveling agent is 2025; the antifungal agent is a mixture of hibiscus bark, white fresh bark, cork, flavescens, pepper, orange peel and normal saline.

[0037] The preparation method of the anti-mildew color paste of the present embodiment m...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 anti-mold color paste is that the anti-mold color paste of the present embodiment includes the following components by weight:

[0043] 10 parts of deionized water, 8 parts of dispersant, 0.8 part of defoamer, 60 parts of titanium dioxide, 0.5 part of antifungal agent, 0.5 part of anti-settling agent, 0.01 part of thickener, and 0.02 part of leveling agent.

[0044] The preparation method of the anti-mildew color paste described in the present embodiment, comprises the steps:

[0045] (1) Add accurately weighed deionized water into the tank, start stirring to a low speed state, add dispersant and defoamer, raise to medium speed to disperse, until the stirring is uniform,

[0046] (2) Then add the pigments in batches, beat and disperse quickly for 20-30 minutes after adding,

[0047] (3) Then reduce the speed to medium speed, add anti-settling agent and anti-mold, stir for 3-5 minutes, then add leveling agent and thic...

Embodiment 3

[0049] The difference between embodiment 3 and embodiment 1 pan-magnesium color paste is that the anti-mildew color paste of the present embodiment comprises the following components by weight:

[0050] 13 parts of deionized water, 8 parts of dispersant, 0.9 part of defoamer, 65 parts of titanium dioxide, 1.3 parts of antifungal agent, 0.3 part of anti-settling agent, 0.04 part of thickener, 0.05 part of leveling agent,

[0051] The preparation method of the anti-mildew color paste described in the present embodiment, comprises the steps:

[0052] (1) Add accurately weighed deionized water into the tank, start stirring to a low speed state, add dispersant and defoamer, raise to medium speed to disperse, until the stirring is uniform,

[0053] (2) Then add the pigments in batches, beat and disperse quickly for 20-30 minutes after adding,

[0054] (3) Then reduce the speed to medium speed, add anti-settling agent and anti-mold agent, stir for 3-5 minutes, then add leveling agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com