Follow-up conveying device of laser processing equipment for continuous cutting

A conveying device and laser processing technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as reducing the applicability of machine tools, affecting the stability of sheet materials, and being difficult to meet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

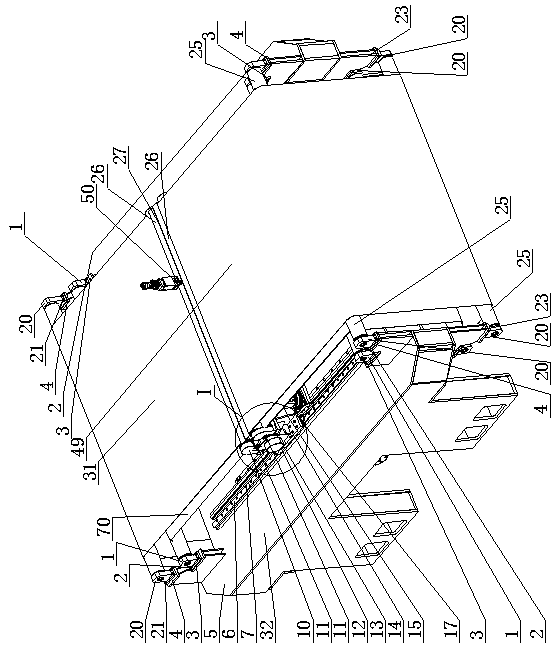

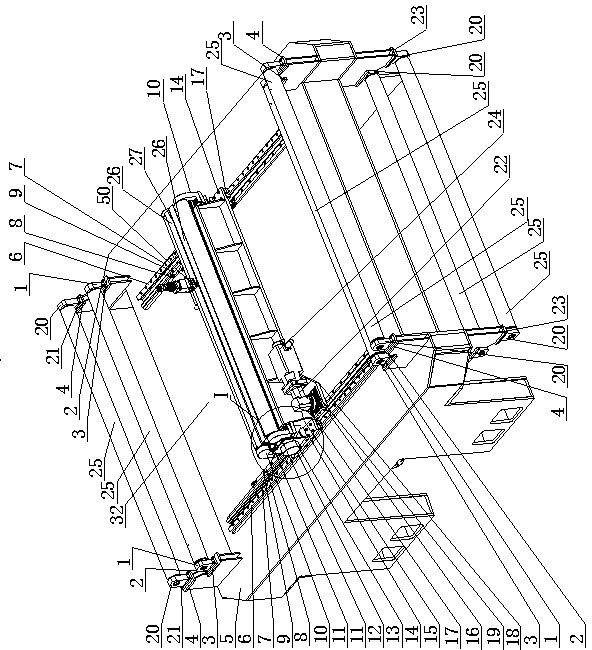

[0070] Embodiment 2: The preparation of this embodiment is the same as that of Embodiment 1 and will not be repeated, except that the arrangement of double conveying devices is adopted.

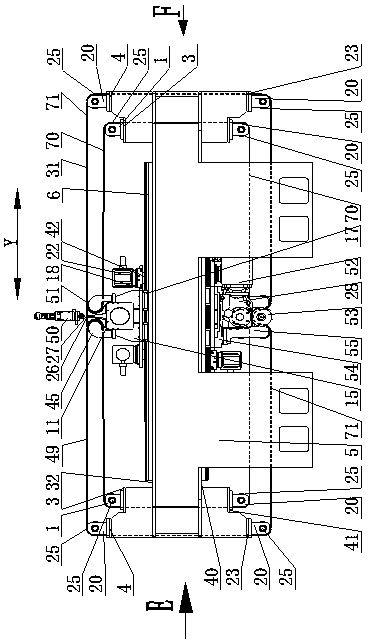

[0071] Such as Figure 19 and 20 As shown, a continuous cutting laser processing equipment follows the conveying device, which includes a frame 5, and on the top surface of the frame 5, an upper movable frame that can reciprocate relative to the frame 5 is arranged side by side under the drive of the upper beam driving device. Crossbeam 15 is provided with parallel upper beam left driven roller 45 and upper crossbeam right driven roller 51 on moving crossbeam 15, is provided with a plurality of frame driven rollers 25 on frame 5, on described frame driven roller 25 The part corresponding to the belt is set and can rotate independently (coaxial double rollers). On the bottom surface of the frame 5, there is also a lower moving beam 54 that moves back and forth relative to the frame under the ...

Embodiment 3

[0076] Embodiment 3: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that the feeding direction (Y direction) adopts a double-belt arrangement. Such as Figure 24 Shown, a kind of laser processing equipment of continuous cutting follows conveying device, and it comprises frame 5, is provided with on the top surface of frame 5 and can move back and forth with respect to frame under the drive of upper beam driving device under the movable crossbeam 15, Be provided with parallel upper beam left driven roller 45 and upper beam right driven roller 51 on upper moving beam 15, be provided with a plurality of frame driven rollers 25 on frame 5, also be provided with lower beam drive on frame 5 bottom surface Driven by the device, the lower moving crossbeam 54 that reciprocates relative to the frame is provided with the first driving roller 30 and the second driving roller 65 arranged up and down in parallel on the lower moving cros...

Embodiment 4

[0081] Embodiment 4: The similarities between this embodiment and Embodiment 3 will not be described in detail. The difference is that an upper movable crossbeam that can move back and forth relative to the frame is arranged side by side on the top surface of the frame 5 under the drive of the upper crossbeam driving device. 15, on each moving beam 15, be provided with parallel upper beam left driven roller 45 and upper beam right driven roller 51, be provided with a plurality of frame driven rollers 25 on the frame 5, on the frame driven roller 25 is provided with a part corresponding to each belt and can rotate independently (coaxial double rollers). The lower crossbeam 54 that moves back and forth relative to the frame under the drive of the lower crossbeam driving device is also arranged side by side on the bottom surface of the frame 5. Each lower moving crossbeam 54 is provided with a first driving roller 30 and a second driving roller 65 arranged up and down in parallel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com