Sheet type giant magnetostrictive magnetic field sensor based on fiber Bragg grating

A giant magnetostrictive and magnetic field sensor technology, which is applied in the use of magneto-optical equipment for magnetic field measurement, the size/direction of the magnetic field, etc., can solve problems such as difficult to use magnetic field measurement, and achieve high reliability, strong anti-interference ability, Ease of forming a sensor network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

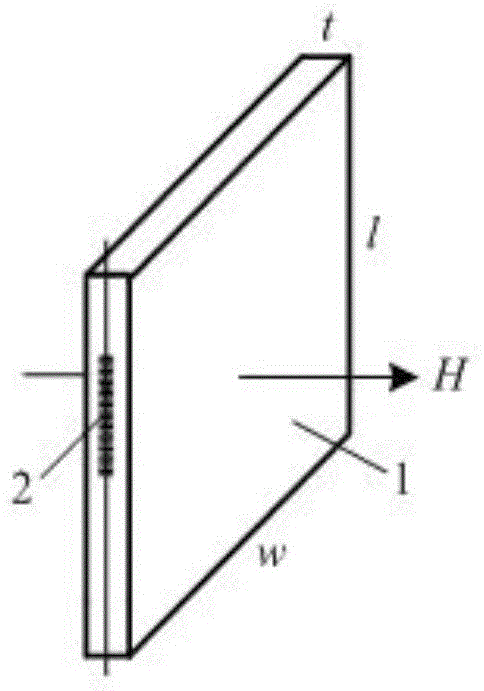

[0021] The sheet type giant magnetostrictive magnetic field sensor based on fiber grating provided by the present invention has a structure such as figure 1 Shown: including giant magnetostrictive sheet 1 and fiber grating 2. The magnetostriction of the giant magnetostrictive sheet 1 is along its thickness direction. The fiber grating 2 is perpendicular to the magnetostrictive direction of the giant magnetostrictive sheet 1, and it is pasted on the side along the length L direction of the giant magnetostrictive sheet 1 to form a sheet-type giant magnetostrictive magnetic field sensor based on a fiber grating.

[0022] The giant magnetostrictive sheet 1 is a sheet made by cutting a TeDyFe rod.

[0023] The thickness t direction of the giant magnetostrictive sheet 1 is the magnetostrictive direction, and the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com