Workshop manufacturing process-oriented active sensing and anomaly analysis method of real-time generating performance

A technology of manufacturing process and analysis method, applied in the direction of total factory control, total factory control, program control, etc., can solve problems such as poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

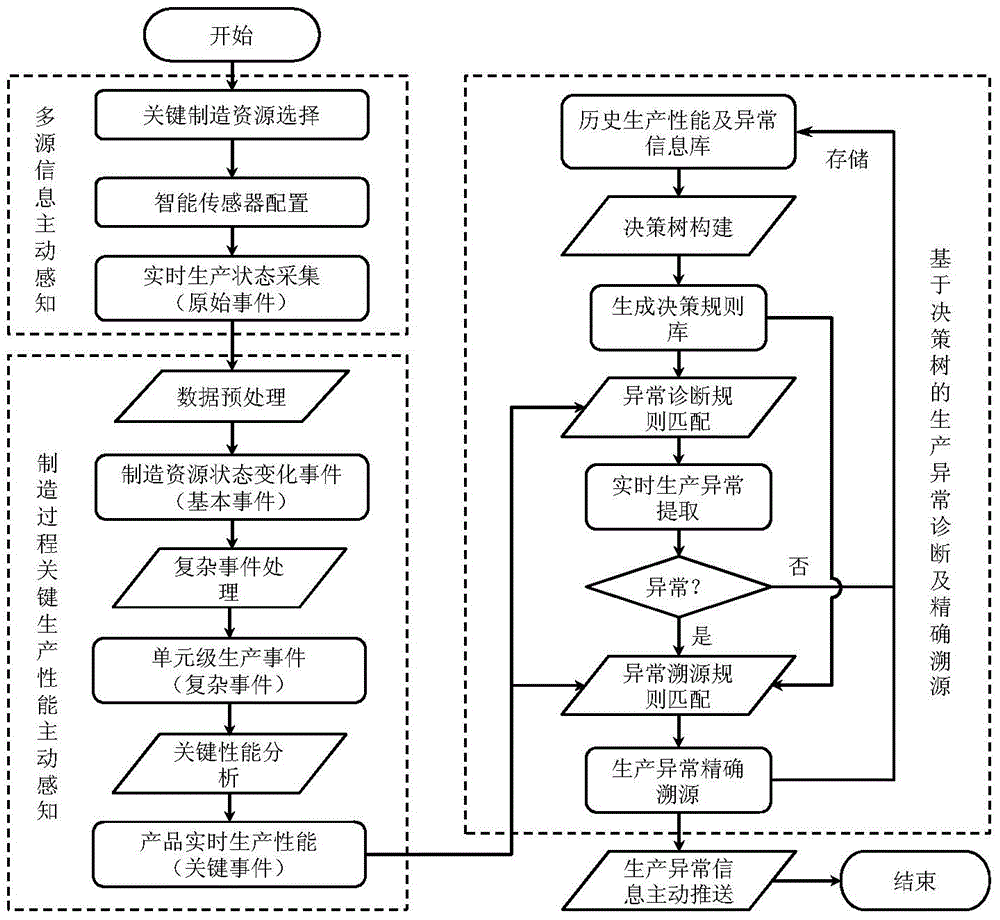

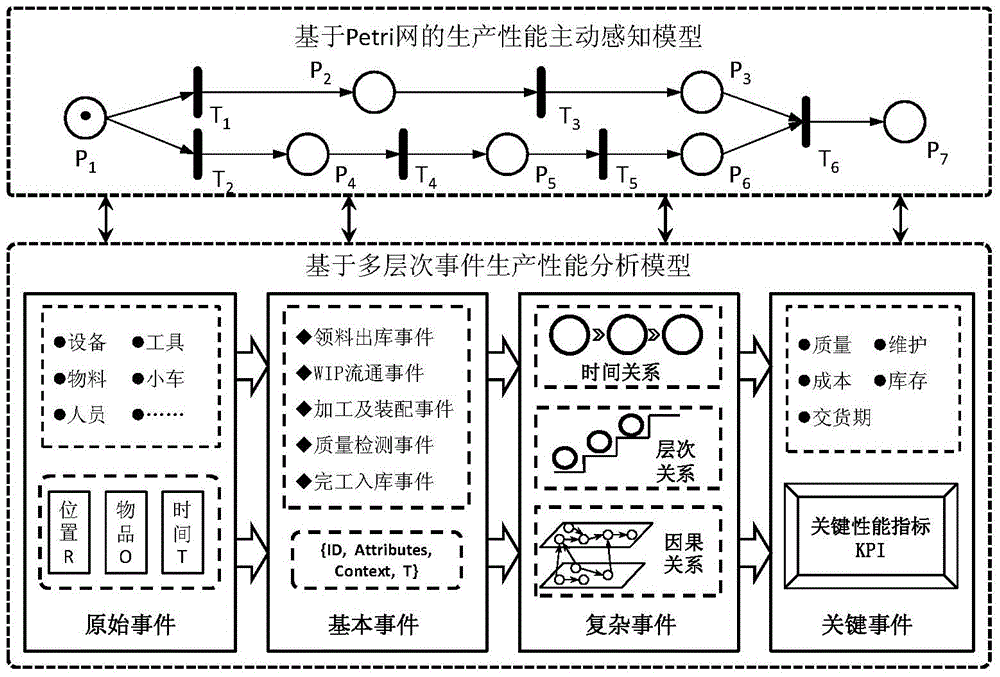

[0064] refer to Figure 1-6 . The specific steps of the real-time generation performance active perception and abnormal analysis method oriented to the workshop manufacturing process of the present invention are as follows:

[0065] The present invention designs an active perception and abnormal diagnosis method for real-time production performance oriented to the workshop manufacturing process. Level, quickly diagnose the cause of the abnormality, and provide a basis for quickly obtaining the optimal scheduling strategy. The specific implementation steps are as follows:

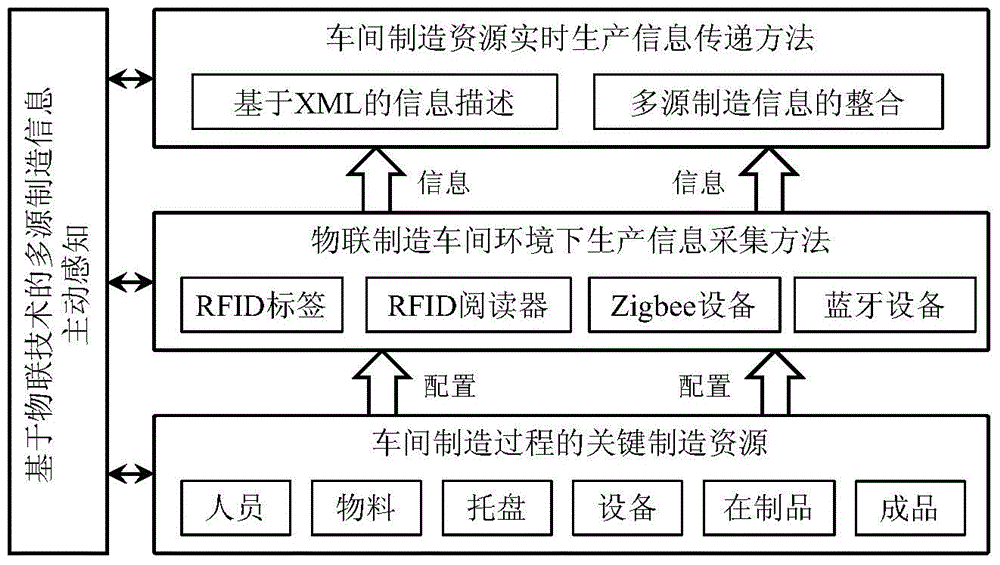

[0066] Step 1: Based on the existing IoT sensing technology, construct an intelligent manufacturing resource that can perceive changes in its surrounding environment and its own operating status, and transmit the real-time status of the manufacturing resource to the upper management system, specifically including the following steps:

[0067] Step 1.1: Based on key production performance information, sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com