Distribution line tour-inspection system based on GIS and GPS

A technology for inspection systems and power distribution lines, applied in information technology support systems, inspection time patrols, data processing applications, etc., can solve the problems of low recording efficiency, error-prone data, and high cost of manual paper media, and achieve battery life. Strong, improve work efficiency, little effect of direct sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

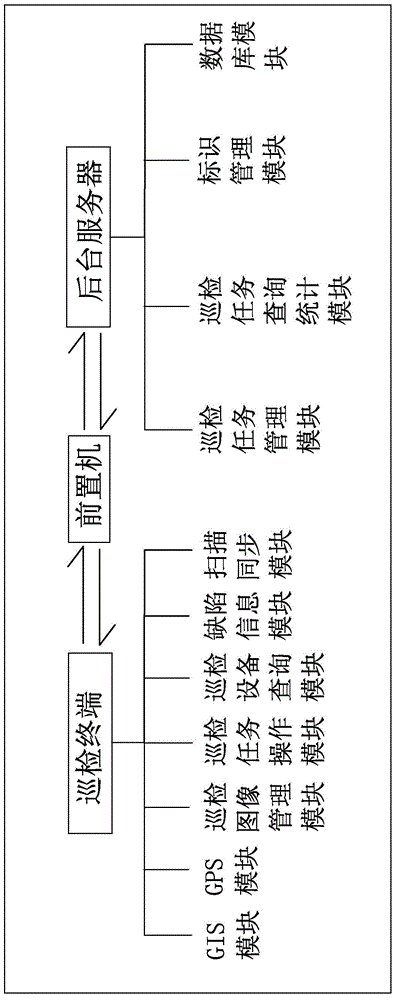

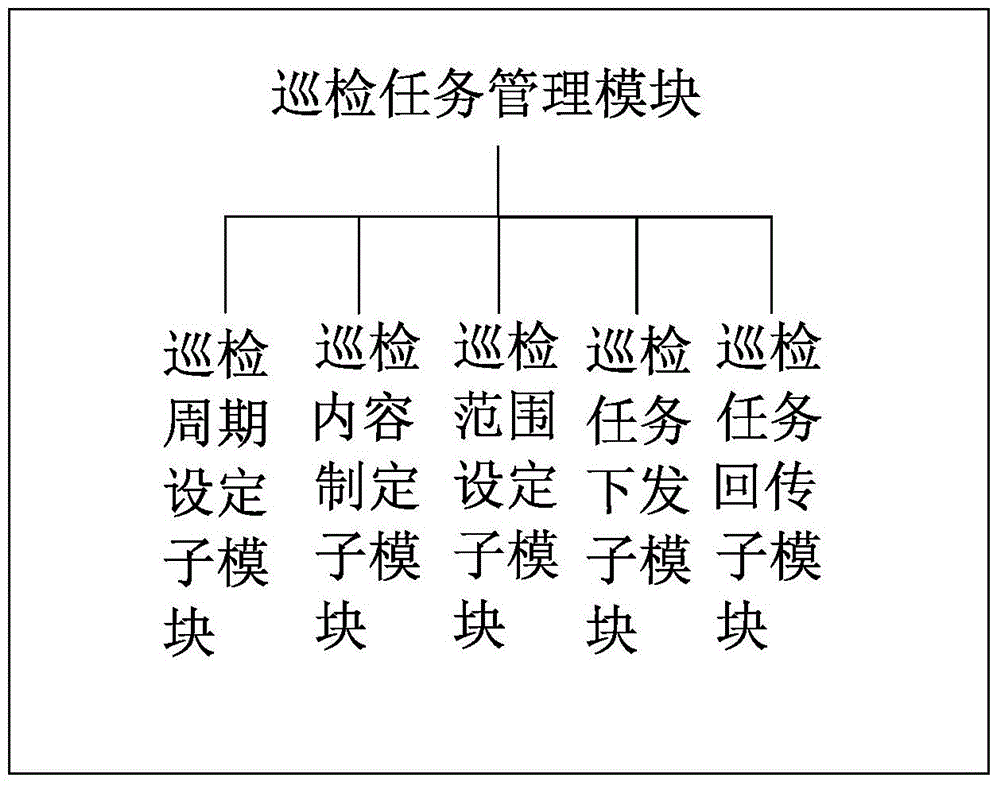

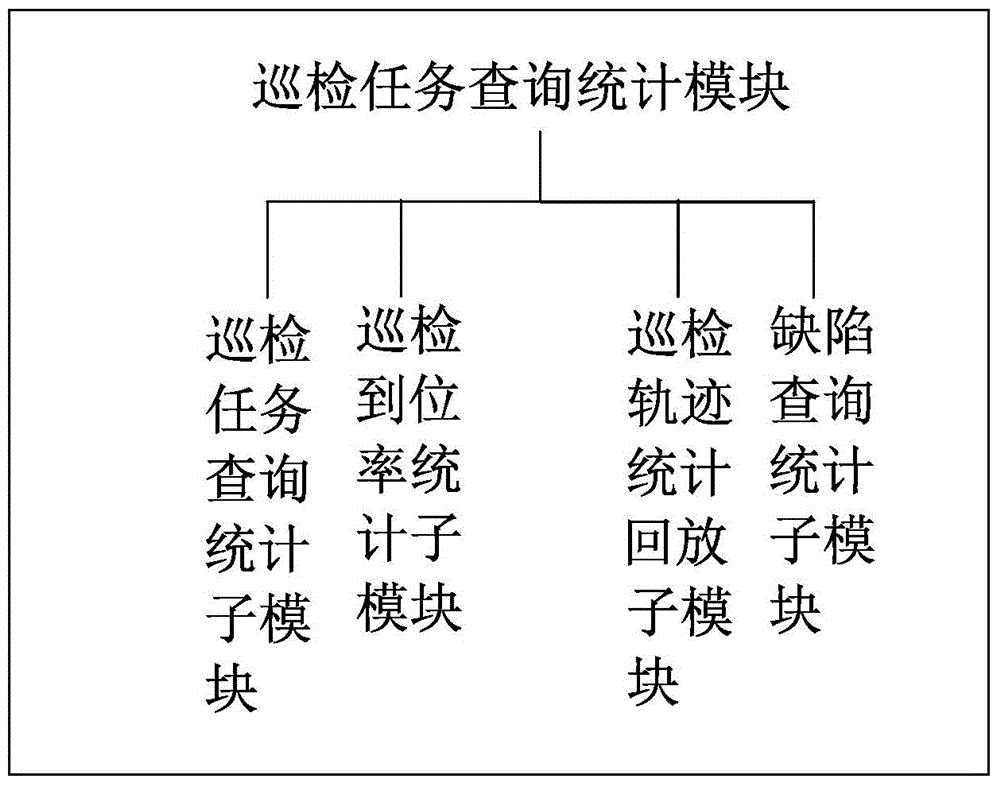

[0022] Referring to the accompanying drawings, a GIS and GPS-based power distribution line inspection system provided by the present invention is composed of an inspection terminal and a background server. Data is transmitted between the inspection terminal and the background server through a front-end computer. The background server is equipped with Inspection task management module, inspection task query statistics module, identification management module, database module, inspection terminal is equipped with GIS module, GPS module, inspection image management module, inspection task operation module, inspection equipment query module, defect information module, scan synchronization module; the patrol inspection task management module includes a patrol inspection period setting submodule, a patrol inspection content generation submodule, a patrol inspection task delivery submodule and a patrol inspection task return submodule; the patrol inspection The task query statistics m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com