Round split conductor with internal optical fibers

A technology with built-in optical fibers and split conductors, which is applied in the direction of fiber mechanical structures, power cables, electrical components, etc., can solve the problems of increased line loss, torsional force, small tensile force, increased processing difficulty, etc., to increase line loss, electric field, etc. Uniform and reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

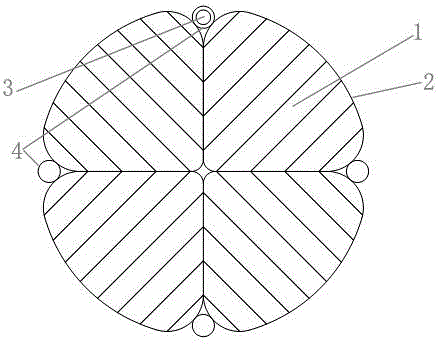

[0022] Such as figure 1 A segmented conductor with a rounded built-in optical fiber is shown, the conductor structure is composed of four fan-shaped conductor strands 1; the fan-shaped conductor strands 1 are provided with insulation to isolate each strand Crepe paper 2; the fan-shaped corners of the fan-shaped conductor strands 1 are provided with a wire bundle 4 with an optical fiber unit 3 directly dragged in the center.

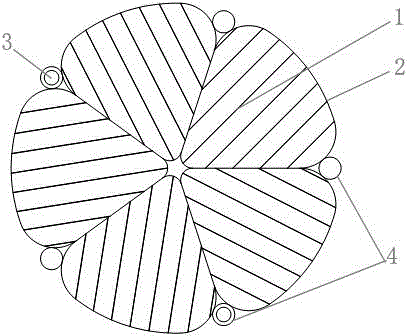

[0023] Such as figure 2 A segmented conductor with built-in optical fiber is shown, the conductor structure is composed of five fan-shaped conductor strands 1; insulation wrinkles are provided between the fan-shaped conductor strands 1 to isolate each strand Paper 2; two wire bundles 4 with optical fiber unit 3 directly dragged between the fan-shaped corners of the fan-shaped conductor strand 1 .

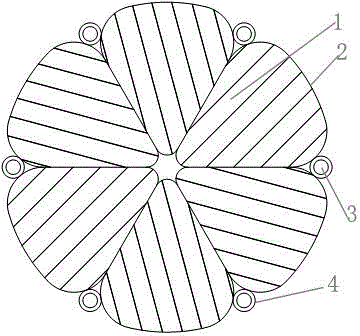

[0024] Such as image 3 A segmented conductor wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com