Substrate baseplate, display baseplate, manufacturing method of substrate baseplate and display device

A manufacturing method and substrate substrate technology, applied in semiconductor/solid-state device manufacturing, instruments, electrical digital data processing, etc., can solve the problems of different thermal expansion coefficients between organic substrates and inorganic films, micro-cracks and easy peeling of inorganic films, etc., to achieve The effect of improving product yield and display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

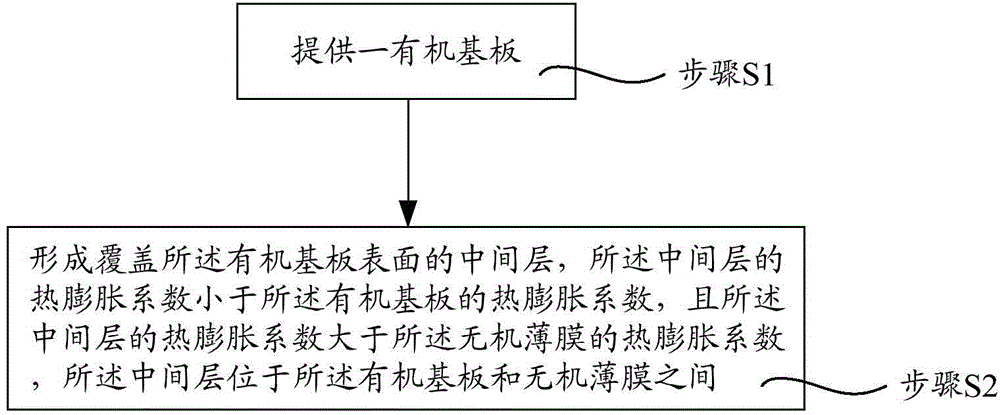

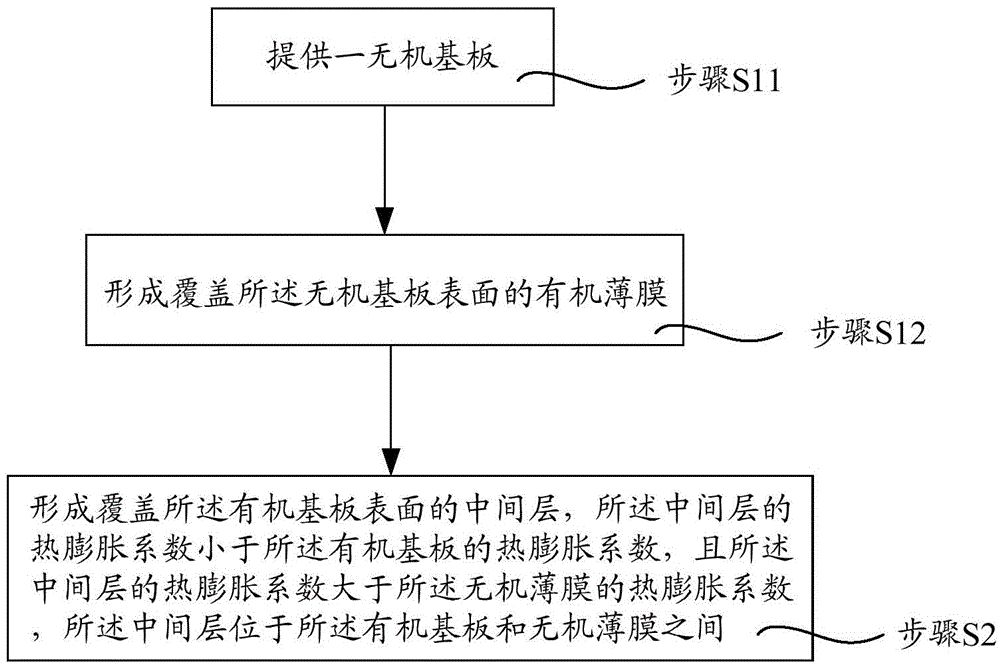

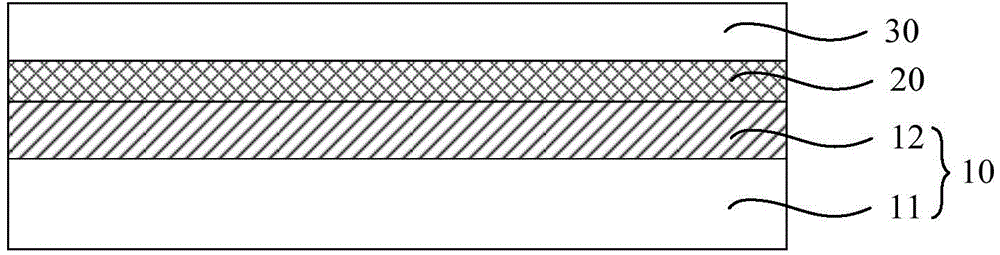

[0056] The present invention provides a base substrate used as a base for an inorganic thin film, the base substrate comprising an organic substrate and an intermediate layer covering the surface of the organic substrate, wherein the thermal expansion coefficient of the intermediate layer is smaller than that of the organic substrate , and the thermal expansion coefficient of the intermediate layer is greater than the thermal expansion coefficient of the inorganic thin film, and the intermediate layer is located between the organic substrate and the inorganic thin film. Among them, the organic substrate has the advantages of better flexibility, lighter weight, and more impact resistance, but its thermal expansion coefficient is large, and the deformation amount at high temperature is large. Since the thermal expansion coefficient of the inorganic material is much smaller than that of the organic material, the setting of the intermediate layer can buffer the influence of the the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com