A safety monitoring system for mine hoist maintenance personnel

A safety monitoring system and maintenance personnel technology, applied in transmission systems, electrical components, services based on location information, etc., can solve the problems of poor communication quality, reliability, stability, danger, etc., to improve safety and technical management level, The effect of a good computer interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] Basic thought of the present invention is:

[0037] By proposing a safety monitoring system for maintenance personnel of a coal mine hoist, the position of the maintenance personnel can be uploaded to the driver in the control room in real time and accurately, and the driver decides whether to move the car according to the location of the maintenance personnel until the maintenance is confirmed The driver can only move the car after the personnel are evacuated to the safe area, which is beneficial to eliminate the hidden safety hazards in the intercom communication process, effectively prevent accidents, and greatly improve the safety of maintenance.

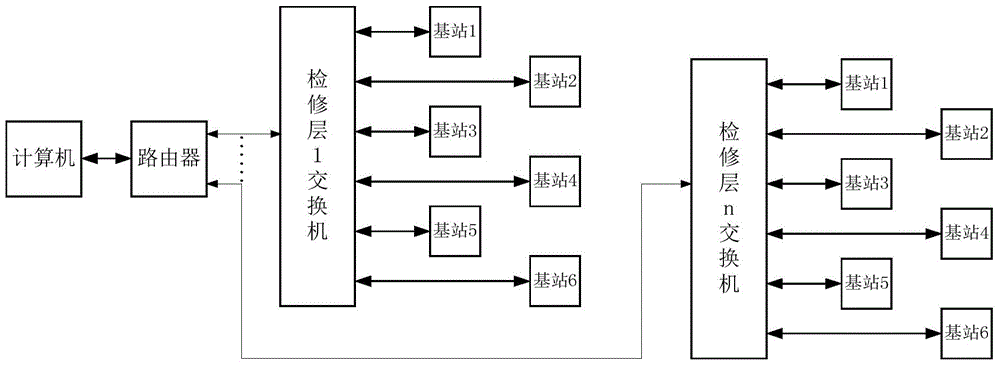

[0038] Specifically, combine figure 1 As shown, a coal mine hoist maintenance personnel safety monitoring system includes a computer 1, a network router 2 and several sets of maintenance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com