Device and method for producing continuous low-temperature large-section atmospheric pressure plasma plumes

An atmospheric pressure plasma and large cross-section technology, applied in the field of plasma, can solve the problems of small cross-section, low time duty cycle, and high plasma plume temperature, and achieve large cross-sectional area, high time duty cycle, and low gas temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, a device for generating a continuous low-temperature large-section atmospheric-pressure plasma plume.

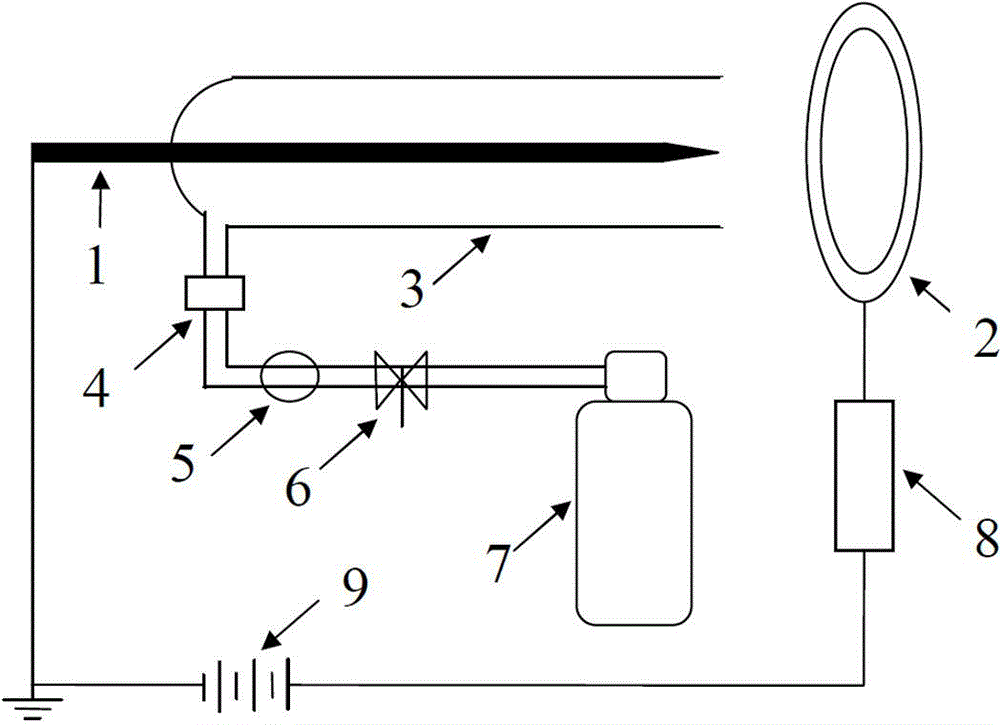

[0038] like figure 1 As shown, the device provided by the present invention includes a spray gun mechanism, an air supply mechanism and a power supply mechanism.

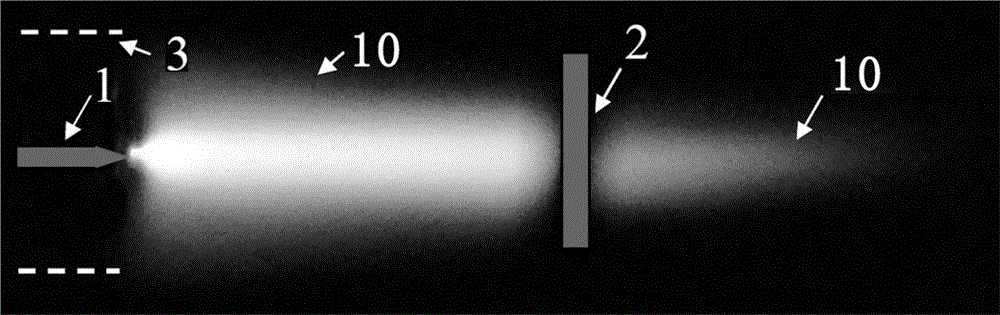

[0039] The spray gun mechanism includes a rod-shaped metal cathode 1 , a hollow closed anode 2 and a U-shaped dielectric tube 3 . One end of the rod-shaped metal cathode 1 is grounded, and the other end is a free end. The U-shaped medium pipe 3 has a sealed end and an open end; the U-shaped medium pipe 3 is placed laterally so that the sealed end and the open end are in the same horizontal plane. The free end of the rod-shaped metal cathode 1 penetrates into the U-shaped dielectric tube 3 from the bottom of the sealed end of the U-shaped dielectric tube 3, and extends to the open end of the U-shaped dielectric tube 3. The free end of the rod-shaped metal cathode 1 is connected to the U-shaped d...

Embodiment 2

[0046] Embodiment 2, a method for generating a continuous low-temperature large-section atmospheric pressure plasma plume.

[0047] The method for producing a continuous low-temperature large-section atmospheric pressure plasma plume provided by the present invention comprises the following steps:

[0048] a. Set up the spray gun mechanism.

[0049] like figure 1 As shown, the spray gun mechanism includes a rod-shaped metal cathode 1 , a hollow closed anode 2 and a U-shaped dielectric tube 3 . One end of the rod-shaped metal cathode 1 is grounded, and the other end is a free end. The U-shaped medium pipe 3 has a sealed end and an open end; the U-shaped medium pipe 3 is placed laterally so that the sealed end and the open end are in the same horizontal plane. The free end of the rod-shaped metal cathode 1 penetrates into the U-shaped dielectric tube 3 from the bottom of the sealed end of the U-shaped dielectric tube 3, and extends to the open end of the U-shaped dielectric t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com