Automatic cylinder lining board assembly platform and control method thereof

A technology for assembling platforms and lining boards, which is applied in the direction of program-controlled manipulators, assembly machines, manufacturing tools, etc., can solve problems such as potential safety hazards, heavy weight, and complex lining board structure, so as to eliminate safety accidents, improve efficiency, and reduce operating intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

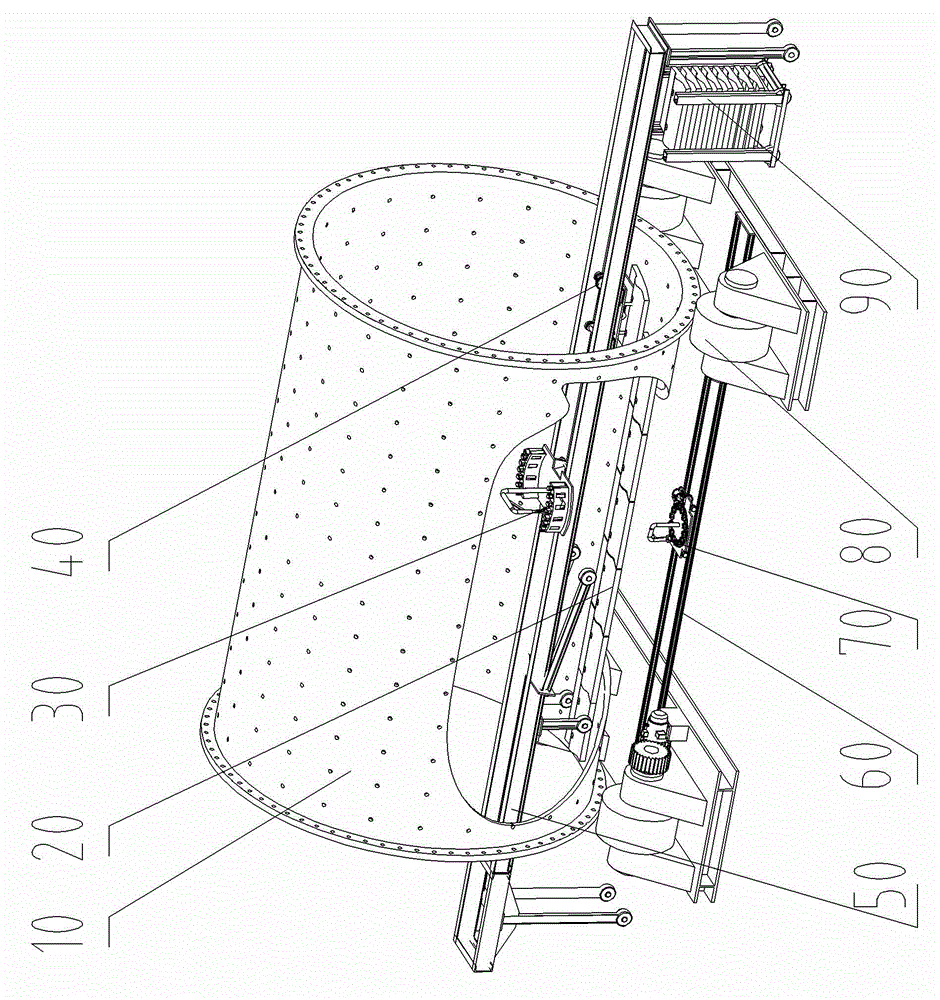

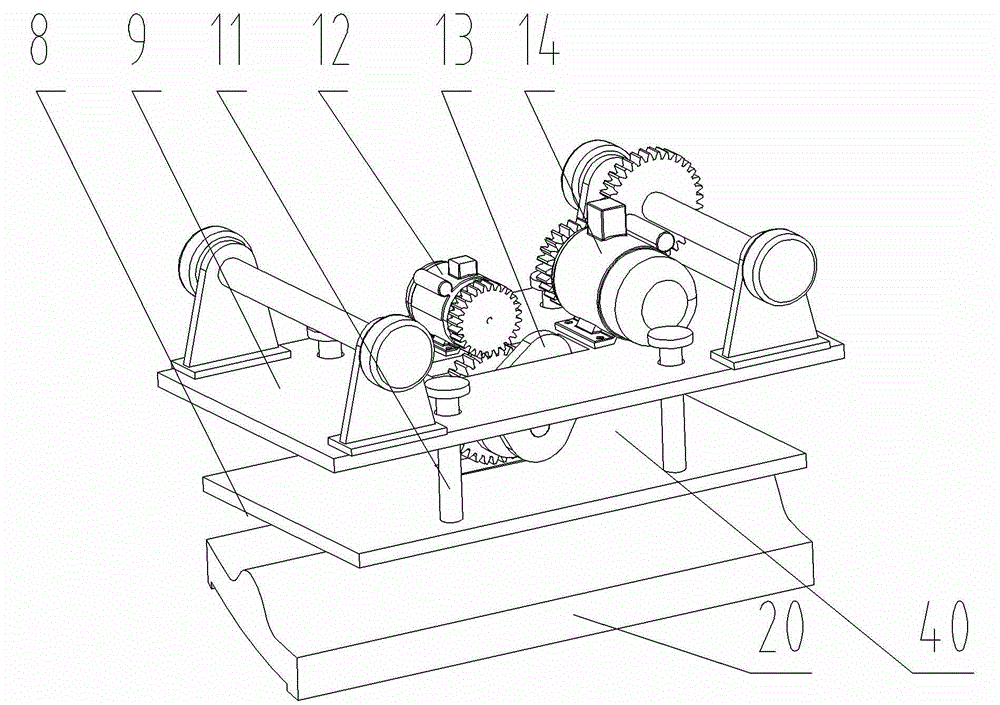

[0033] As shown in the figure, the cylinder liner automatic assembly platform of the present invention includes correspondingly arranged horizontal upper rails 50 and horizontal lower rails 60. The upper part of the upper rail 50 is provided with fastening bolt storage, automatic delivery and placement trolleys 30, and the lower part of the upper rail 50 is provided with liners. The plate is automatically conveyed and picked up by a trolley 40, the lower track 60 is provided with a trolley 70 for automatic delivery and tightening of nuts, and one end of the upper track 50 is provided with a liner plate storage trolley 90; The following track 60 is arranged on the support wheel set 80 .

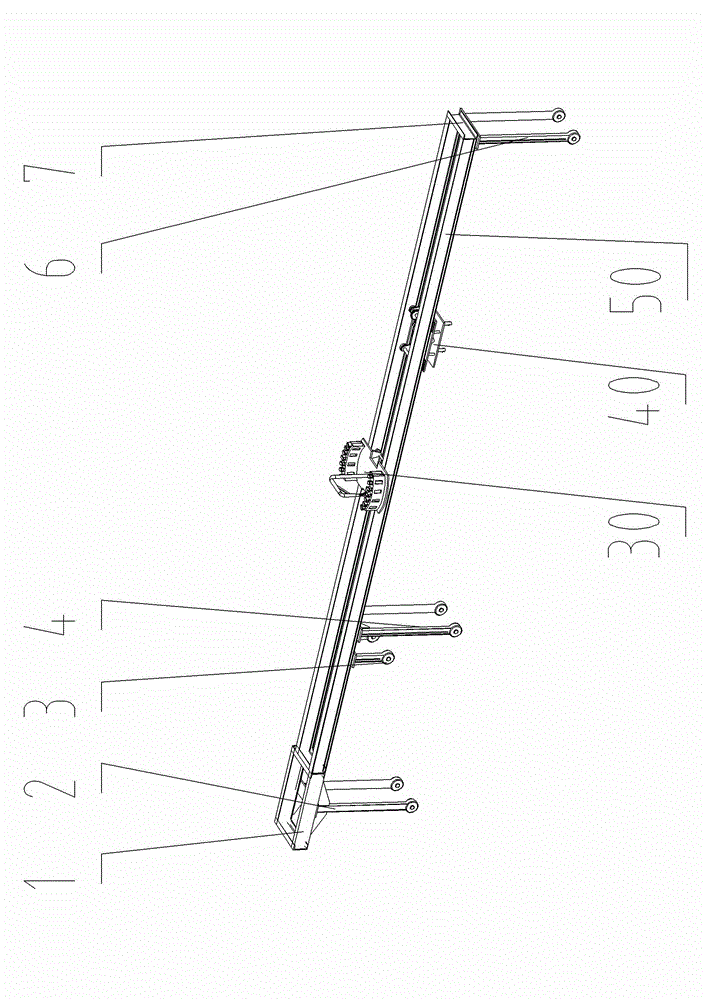

[0034] The two ends of the upper track 50 are respectively provided with a first platform body 1 and a second platform body 7, the lower end of the first platform body 1 is provided with a first cylinder outer support leg 2, and the lower end of the second platform body 7 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com