Automatic material seal for use in processing process of cottonseed oil

A processing process, cottonseed oil technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of high labor intensity and unsafe accidents of workers, and achieve the effect of reducing labor intensity of workers and eliminating unsafe accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

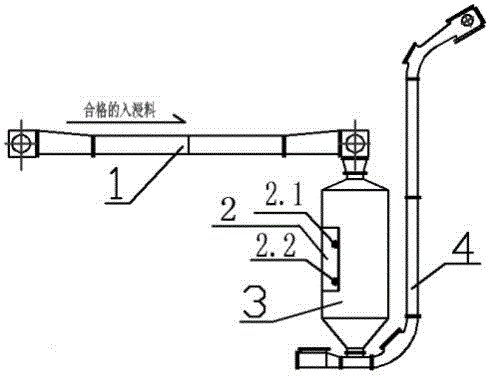

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] This embodiment is aimed at the feeding device used in the processing of cottonseed oil, including a feeding flat scraper 1, a high and low material level controller 2, a storage box 3, and a feeding buried scraper 4, wherein the high and low material level The controller 2 is installed in the material storage box 3. The high and low material level controller 2 is equipped with a high material level probe 2.2 and a low material level probe 2.1. The high material level probe 2.2 is installed at 1.4m of the material storage box 3. The probe 2.1 is installed at 1.2m of the storage box 3, and the connection line of the high and low material level controller 2 is connected to the frequency converter of the motor of the feed buried scraper 4. When the material level of the storage box 3 is higher than 1.4m, the feed The feeding speed of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com