Shovel for chemical production

A chemical production and shovel technology, applied in the field of chemical production application tools, can solve problems such as not easy to loosen, low work efficiency, easy to slip, etc., to achieve the effects of preventing slipping and abrasion, high production efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

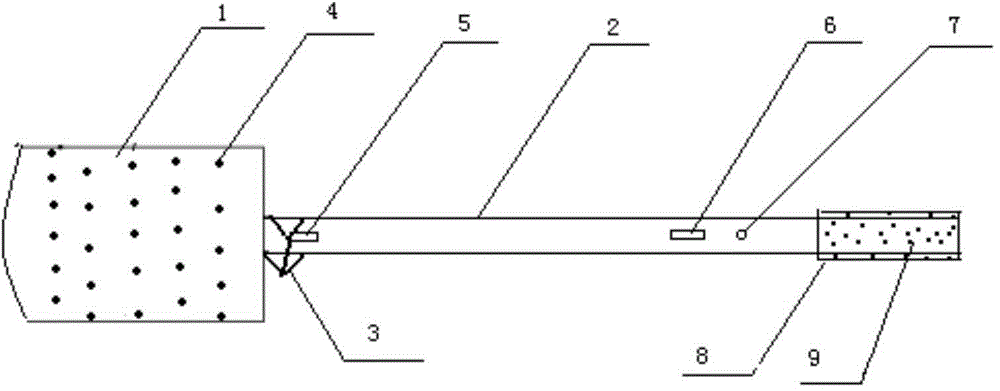

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] The invention provides a shovel for chemical production, which includes a shovel body 1 and a handle 2 fixedly connected to the shovel body 1. It is characterized in that: a foot 3 is provided under the handle 2, and the foot 3 is located between the handle 2 and the handle 2. At the joint of the shovel body 1, when the operator temporarily puts the shovel into the raw material tank, the handle 2 can be supported by the legs 3, and the handle 2 is suspended to prevent the handle 2 from being stained with chemical raw materials.

[0014] The front end of the shovel body 1 is arc-shaped, and the front of the shovel body 1 is provided with a circular protrusion 4, so that the reacting material can move in waves on the shovel body 1, which is conducive to loosening the material and reacting more fully.

[0015] The handle 2 is a hollow struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com