Corrosion resistant method and structure of steel column base with shoe plate

A shoe plate and steel column technology, applied to building components, building insulation materials, etc., can solve problems such as easy accumulation of water or corrosive liquid, reduced structural durability, and easy corrosion of steel column feet, etc., to achieve simple and convenient force transmission path, Solve the effect of easy corrosion and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

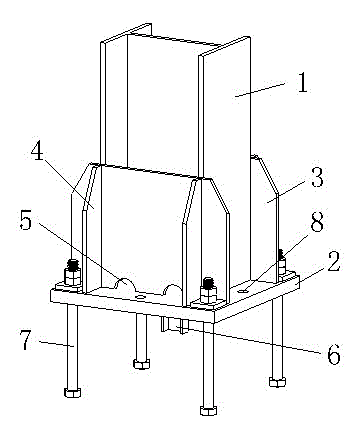

[0016] An anti-corrosion method for steel column feet with shoe plates, such as figure 1 shown. The method is to drill a set of drainage holes at the bottom of the shoe plate welded with the I-shaped steel wing plate and the bottom plate, so as to drain the accumulated water or corrosive liquid in the closed space at the foot of the steel column in time, so as to realize the steel column with shoe plate Antiseptic purpose for feet. The drain hole adopts a semicircular hole or a rectangular hole, and a gate shape is formed between the bottom surface of the hole and the bottom plate to expand the drain channel.

[0017] The steel column foot structure with shoe plate formed according to the aforementioned method includes a base plate 2, the top surface of the base plate 2 is welded to the bottom end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com