Valve with PVD coated surface

A valve and coating technology, which is applied in the field of engine valve mechanism and engine parts, can solve the problems of shortened service life of the valve, decreased performance, and harsh working environment of the valve, and achieve the effect of prolonging the service life and improving the service life

Inactive Publication Date: 2015-03-18

扬州光辉汽车零部件有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The working environment of the valve is particularly harsh, high temperature (about 2200 degrees), high pressure (6-10MPa), high wear and high movement frequency (when the engine is 3000 rpm, the valve opens and closes 1500 times / min). The service performance is obviously reduced, resulting in a significant shortening of the service life of the valve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

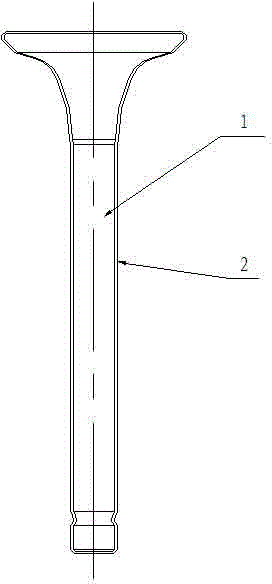

[0007] Such as figure 1 As shown, the present invention includes a valve body 1 , and a wear-resistant PVD coating 2 is provided on the outer periphery of the valve body 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a valve with the PVD coated surface and relates to the technical field of engine parts, in particular to the technical field of engine gas distributing mechanisms. The valve comprises a valve body, and a wear-resistance PVD coating is arranged on the periphery of the valve body. The valve is made of the material of ustenitic stainless steel 21-4N, and the wear-resistance PVD coating with the certain thickness coats the surface by the vapor phase deposition method. The valve has the temperature resistance, high-temperature oxidation resistance, corrosion resistance and impact resistance, the fine-performance engine can be met, the performance is maintained in the high temperature state, and the service life of the valve can be prolonged.

Description

technical field [0001] The invention relates to the technical field of engine parts, in particular to the technical field of engine valve trains. Background technique [0002] As a very important part of the engine, the valve should have the following points as the engine develops in the direction of high speed, high power, low emission and low energy consumption: (1) good wear resistance; (2) good wear resistance Thermal, good thermal conductivity; (3) It can still maintain its hardness and strength under high temperature and high pressure, and can withstand impact; (4) It will not oxidize and corrode under high temperature; (5) The valve is light in weight. The working environment of the valve is particularly harsh, high temperature (about 2200 degrees), high pressure (6-10MPa), high wear and high movement frequency (when the engine is 3000 rpm, the valve opens and closes 1500 times / min). The service performance is obviously reduced, resulting in a significant shortening ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01L3/04

CPCF01L3/04

Inventor 杜举才徐巍巍

Owner 扬州光辉汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com