Heat exchanger arrangement and production method

A manufacturing method and technology of heat exchangers, applied to heat exchanger sealing devices, indirect heat exchangers, heat exchanger types, etc., can solve problems such as insufficient sealing quality, unacceptable cost, adverse effects on heat exchanger efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

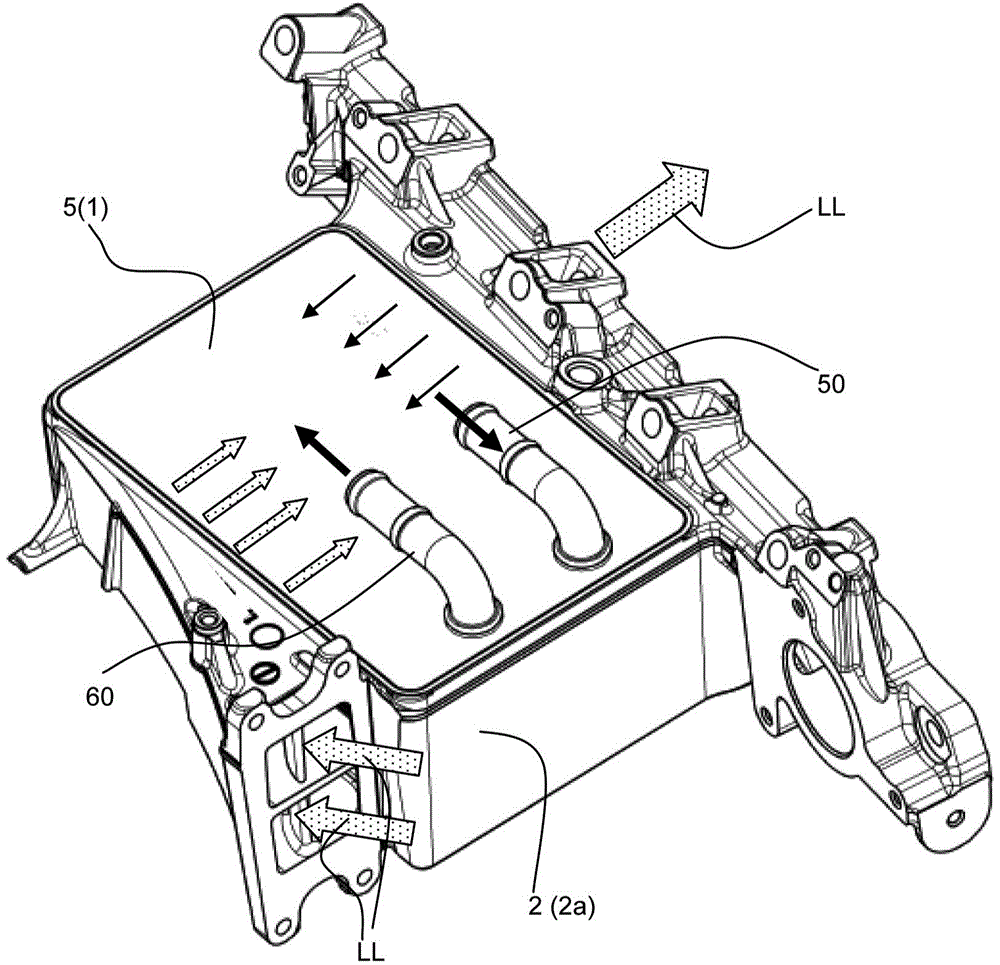

[0028] Such as figure 1 , 8 and 9, as an indirect charge air radiator in a motor vehicle for cooling the compressed charge air fed to an internal combustion engine. The heat exchanger arrangement can also be used for other purposes and also outside the field of motor vehicle applications.

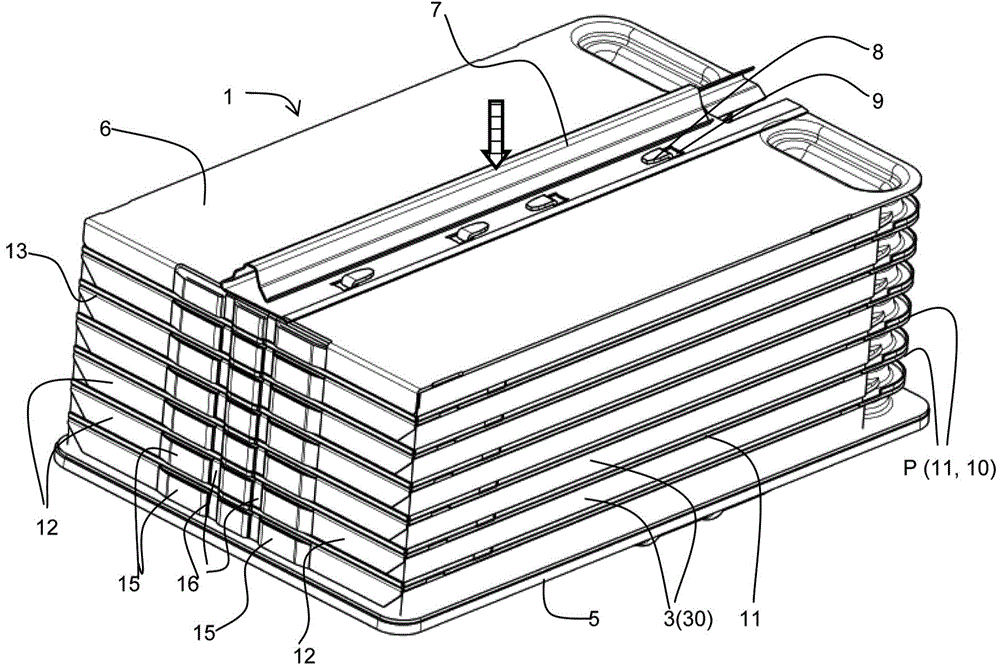

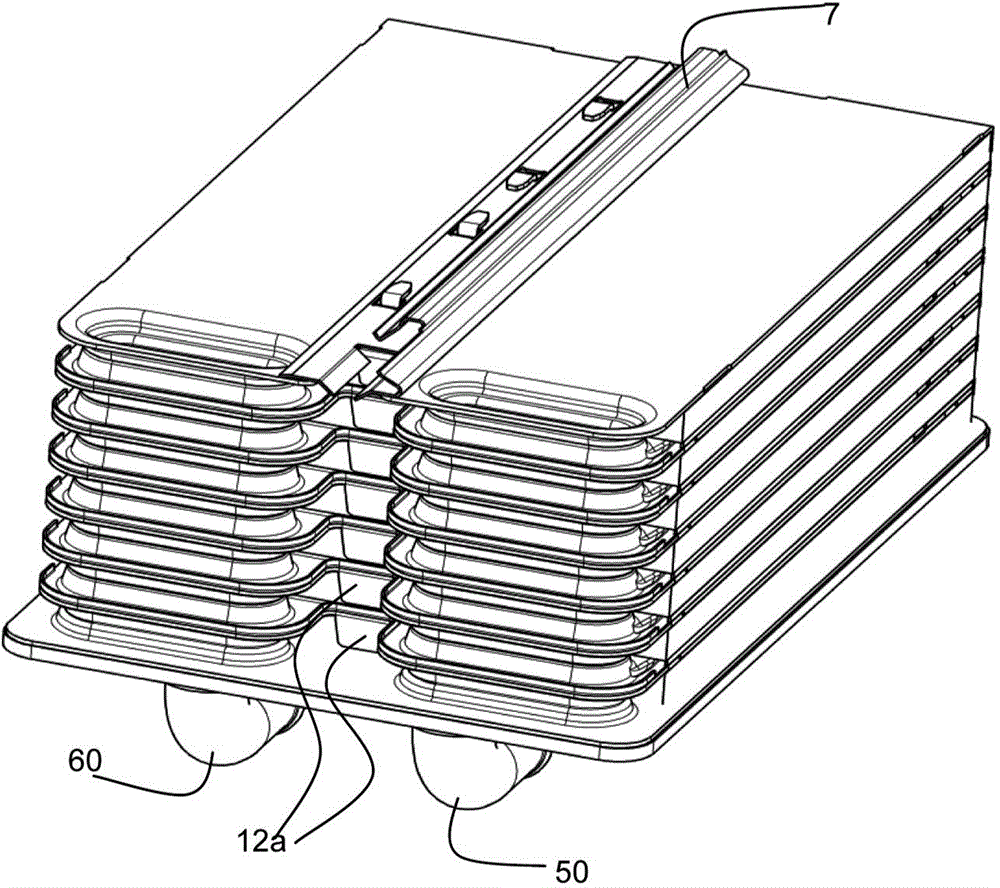

[0029] exist Figures 1 to 3 An inlet 50 and an outlet 60 for the cooling liquid can be seen in , which are fastened to the top plate 5 which belongs to the radiator block 1 . from figure 1 In particular the external features of the housing 2 shown in the figure should be appreciated that there is an inlet for the charge air LL to be cooled on the housing 2 and an inlet for the already cooled charge air LL on the opposite side (not shown). Outlet for cooled charge air, the inlet and outlet are indicated by square arrows.

[0030] The radiator block has a flow path 10 for the cooling liquid, which is formed in the illustrated embodiment by a pair of plates P (consisting of plates 11A, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com