Photomask and overlay-accuracy monitoring method of same

A technology for overlay accuracy and photomask, which is applied in the field of photomask and photomask overlay accuracy monitoring, can solve the problems of difficult process and inconvenient monitoring for photomask overlay accuracy monitoring, shortens the work cycle, The effect of simplifying work and good position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

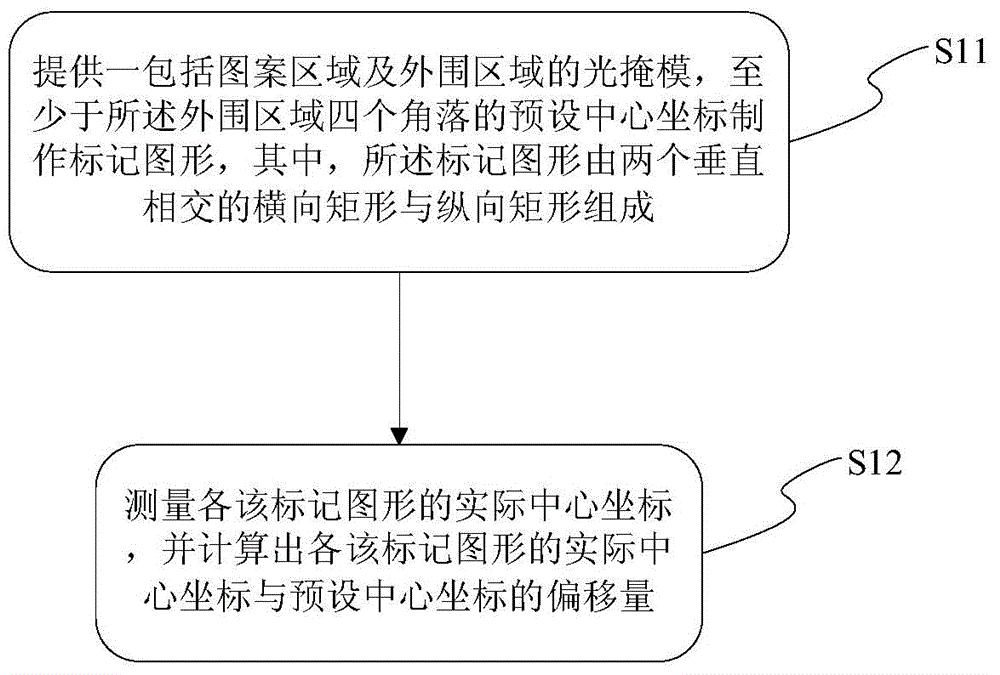

[0049] like Figure 1 ~ Figure 4 As shown, this embodiment provides a method for monitoring the overlay accuracy of a photomask, which at least includes the following steps:

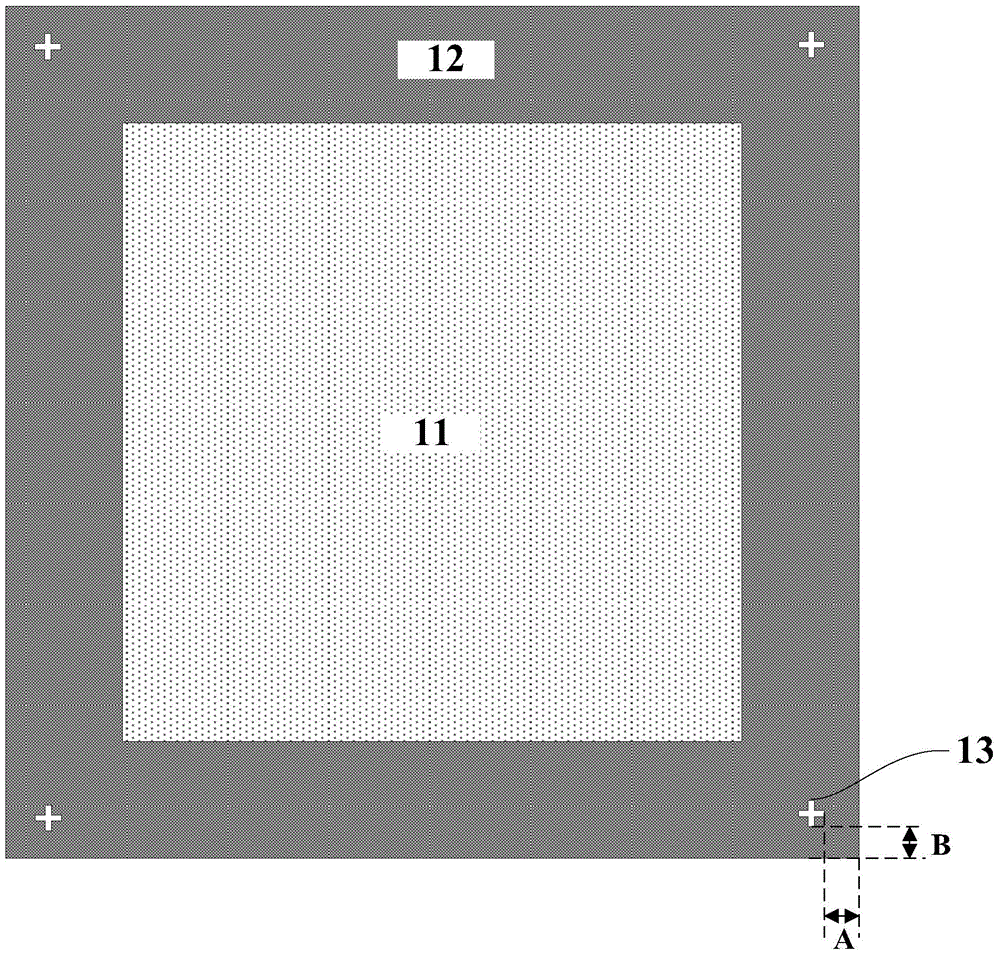

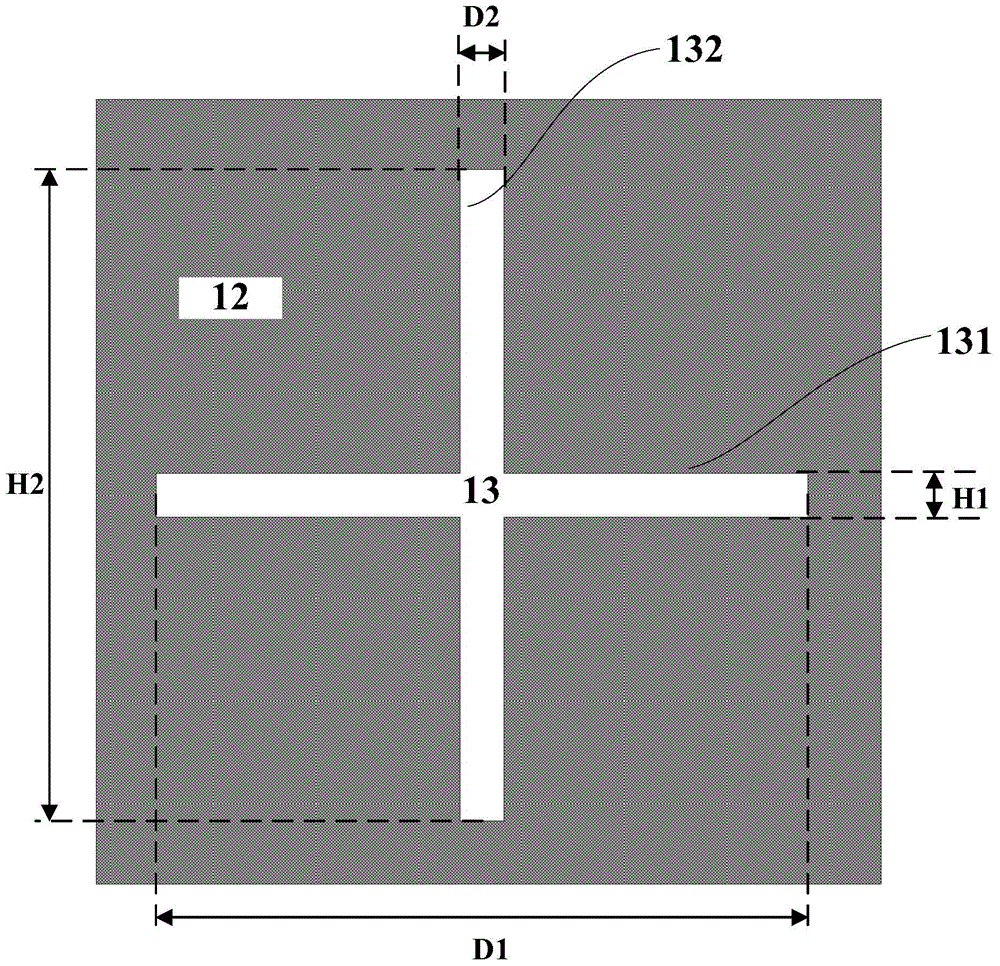

[0050] like Figure 1 ~ Figure 3 As shown, step 1) S11 is performed first, providing a photomask including a pattern area 11 and a peripheral area 12, at least at the preset central coordinates of the four corners of the peripheral area 12 to make a mark pattern 13, wherein the mark The graph 13 is composed of two vertically intersecting horizontal rectangles 131 and vertical rectangles 132 .

[0051]As an example, the photomask is composed of a light-transmitting layer and a light-shielding layer bonded to the surface of the light-transmitting layer. Specifically, the transparent layer is glass, and the light-shielding layer is chrome.

[0052] The graphic area 11 is used to make photolithographic patterns required by the photolithography process. The four corners of the peripheral region 12 are gener...

Embodiment 2

[0071] like figure 2 and image 3 As shown, the present embodiment provides a photomask, comprising:

[0072] Graphics area 11 and a peripheral area 12 surrounding said graphics area;

[0073] The four corners of the peripheral area 12 respectively have marking patterns 13 , and the marking patterns 13 are composed of vertically intersecting horizontal rectangles 131 and vertical rectangles 132 .

[0074] As an example, the photomask is composed of a light-transmitting layer and a light-shielding layer bonded to the surface of the light-transmitting layer. Specifically, the transparent layer is glass, and the light-shielding layer is chromium. The marking pattern 13 is a light-transmitting pattern formed by removing part of the light-shielding layer.

[0075] The graphic area 11 is used to make photolithographic patterns required by the photolithography process. The four corners of the peripheral region 12 are generally not used to make photolithographic patterns, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com