Electrical connection arrangement for an ignition coil

A technology for connecting device and ignition coil, which is applied in the field of ignition coils and thin wires used to form cold contacts on ignition coils, and electrical contacts are surrounded by paint, can solve problems such as problems with electrical contacts, reduce structural size, ensure The effect of compactness, optimal arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

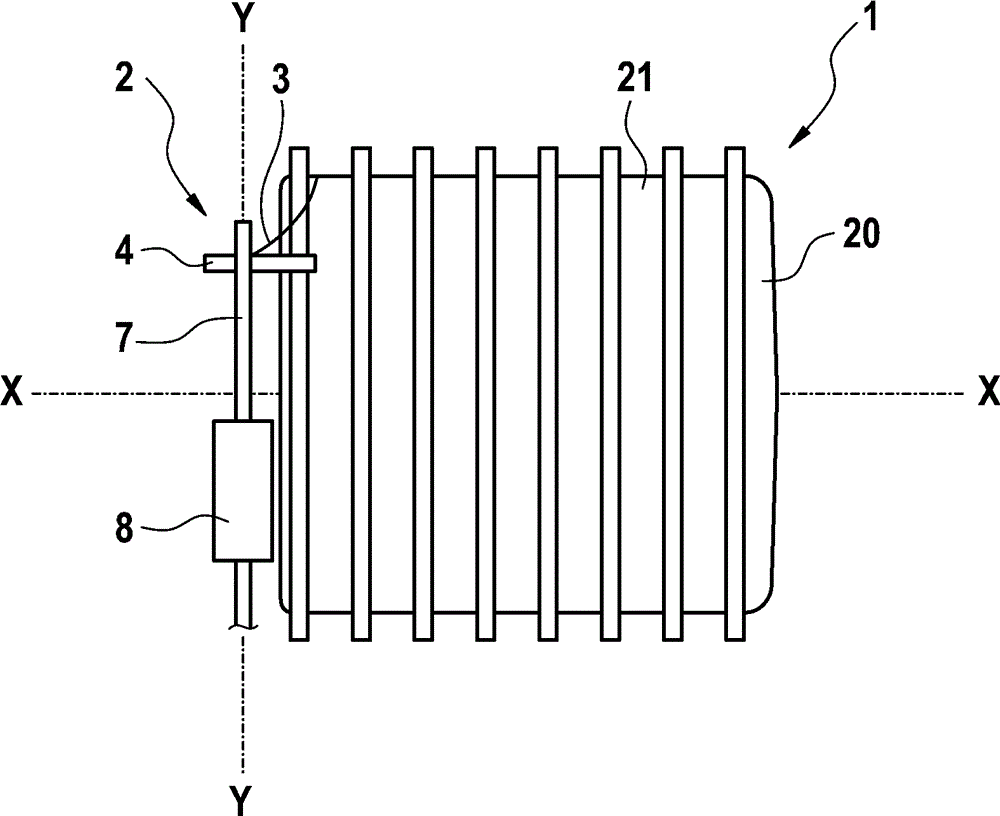

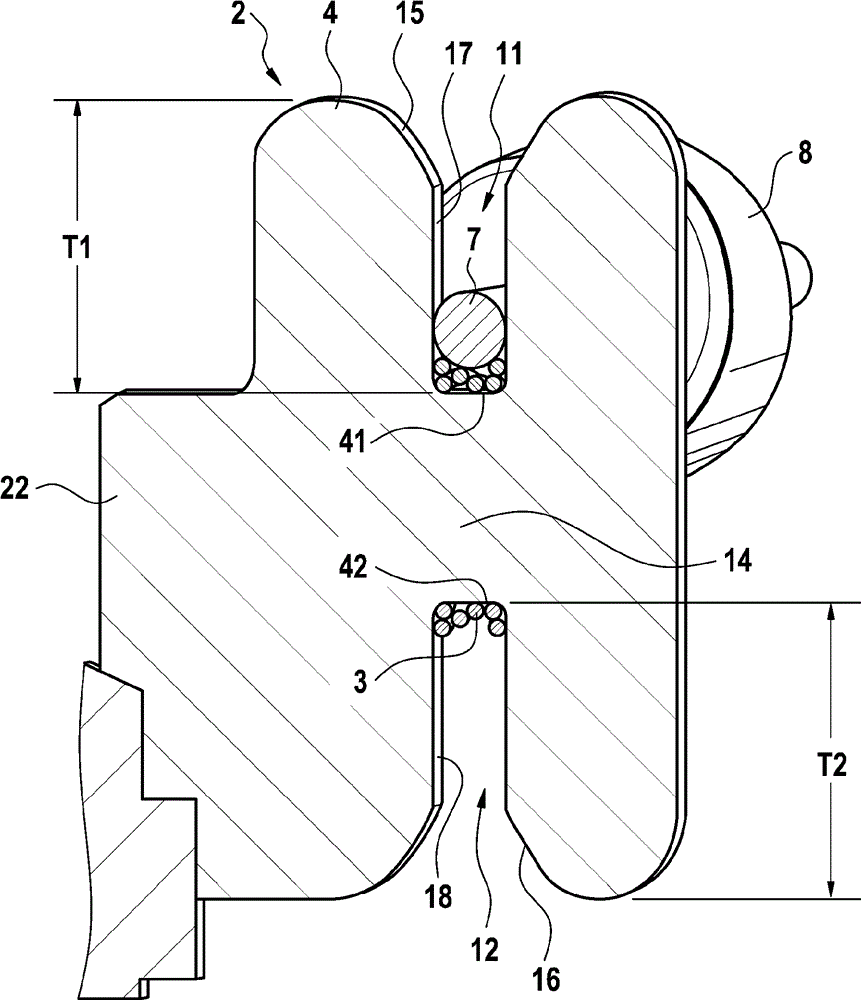

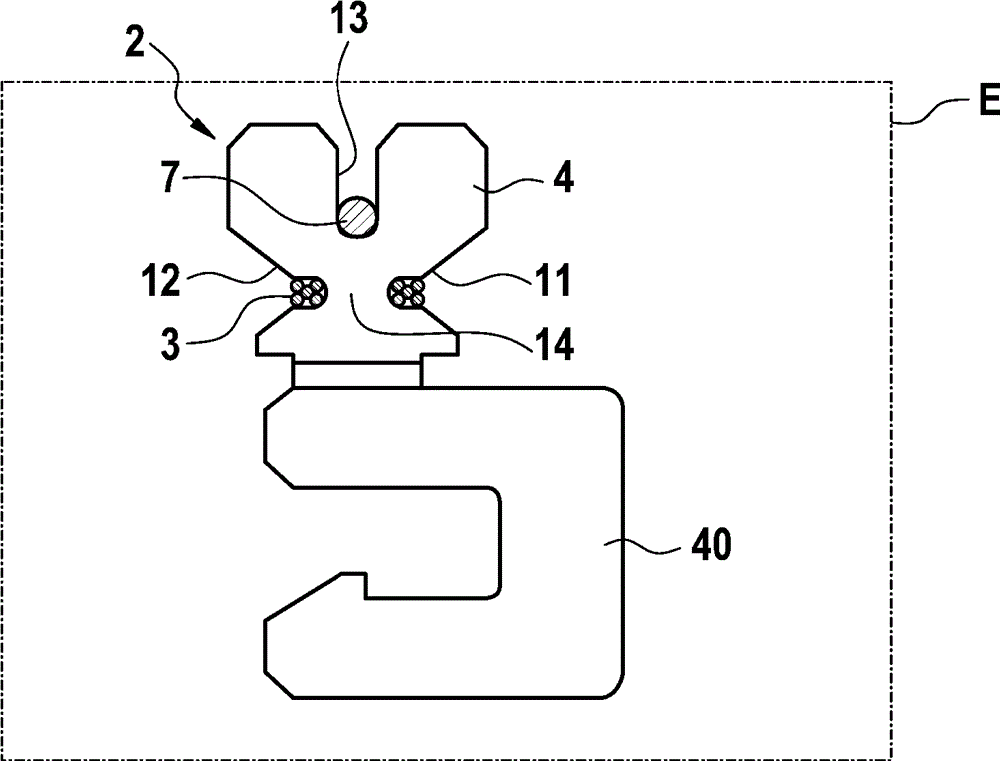

[0022] Refer below Figures 1 to 3 The electrical connection device 2 for the ignition coil 1 is described in detail.

[0023] as from figure 1 It can be seen in the figure that the ignition coil 1 according to the invention comprises an electrical connection device 2 and a coil body 20 with a plurality of surrounding chambers 21 in which enameled wire 3 is wound multiple times.

[0024] The electrical connection device 2 comprises a plate-shaped contact element 4 which is arranged only in the plane E. FIG. The contact element 4 has a first recess 11 and a second recess 12 which form a constriction region 14 between them. In this case, the first recess 11 and the second recess 12 are arranged opposite one another and have the same depth. as from figure 2 It can be seen that the enameled wire 3 is wound multiple times around the constriction region 14 and leads to the coil body 20 . Here, a first introduction region 15 and a second introduction region 16 for easier windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com