Separator for energy storage device, laminated body, and porous membrane

A technology for electrical storage equipment and separators, which is applied in the field of separators for electrical storage equipment, laminates and porous membranes, and can solve the problems of insufficient adhesion and insufficient bonding between reactive polymers and porous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

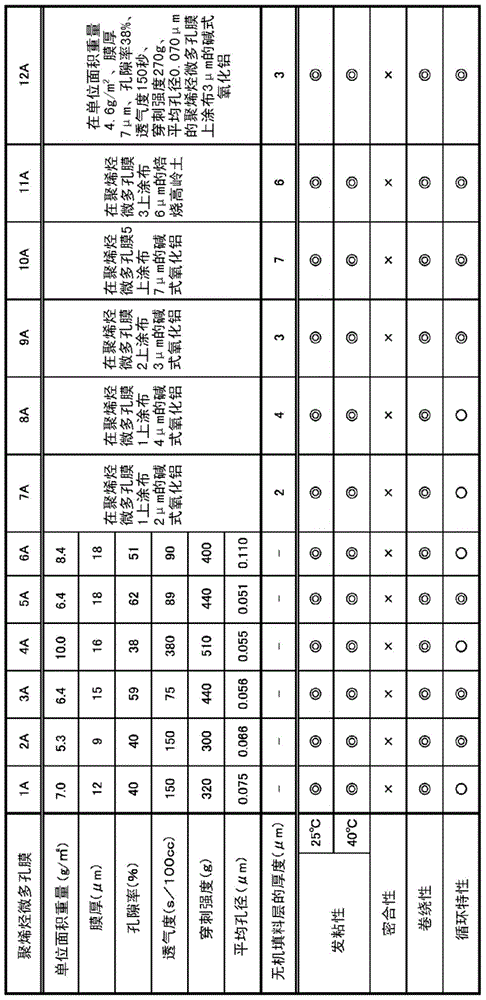

[0052] [Separators for electrical storage devices]

[0053] The separator for an electrical storage device (hereinafter, simply referred to as a "separator") according to the present embodiment has:

[0054] a polyolefin microporous membrane (hereinafter also simply referred to as "microporous membrane"), and a thermoplastic polymer covering layer covering at least a part of the surface of at least one side of the polyolefin microporous membrane,

[0055] The thermoplastic polymer covering layer is a layer in which a portion containing the thermoplastic polymer and a portion not containing the pre-thermoplastic polymer are present in the form of sea islands on the polyolefin microporous membrane,

[0056] the thermoplastic polymer contained in the aforementioned thermoplastic polymer cover layer has at least 2 glass transition temperatures,

[0057] At least one of the aforementioned glass transition temperatures exists in the region of less than 20°C,

[0058] At least one of...

no. 2 Embodiment approach

[0252] The porous membrane of this embodiment

[0253] having: a polyolefin microporous membrane, and a thermoplastic polymer cover layer covering at least a part of the surface of at least one side of the polyolefin microporous membrane,

[0254] The glass transition temperature of the thermoplastic polymer contained in the thermoplastic polymer covering layer is -10°C or more and 40°C or less, and

[0255] The degree of swelling of the thermoplastic polymer with respect to the electrolytic solution is 5 times or less.

[0256] In the second embodiment, other aspects are the same as those described in the first embodiment except for the aspects described later.

[0257] (glass transition temperature)

[0258] The thermoplastic polymer of the present embodiment has a glass transition temperature of preferably -10°C to 40°C, more preferably 0°C to 35°C, still more preferably 15°C to 30°C. In this embodiment, when the glass transition temperature of the thermoplastic polymer ...

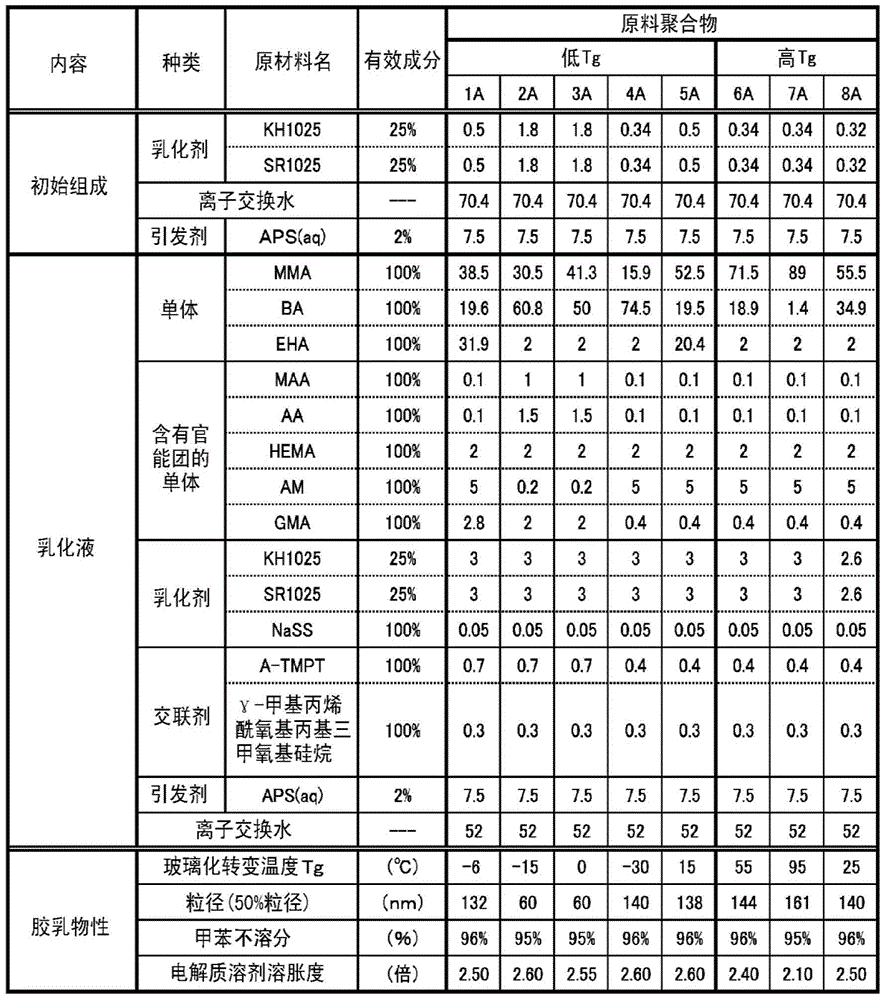

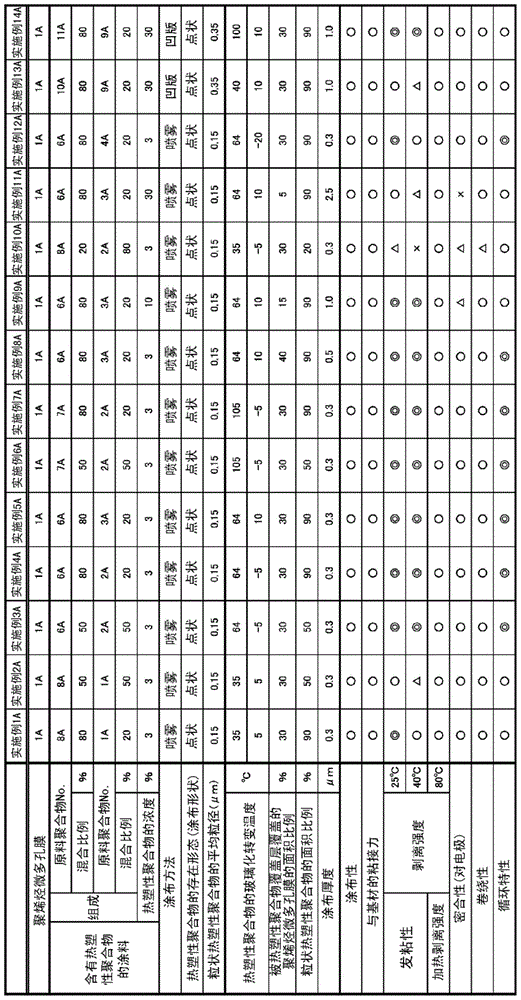

Embodiment

[0272] Hereinafter, although this invention is demonstrated more concretely based on an Example and a comparative example, this invention is not limited to these Examples. The measurement methods and evaluation methods of various physical properties used in the following production examples, examples, and comparative examples are as follows. In addition, unless otherwise specified, various measurements and evaluations were performed under the conditions of room temperature 23 degreeC, 1 atmospheric pressure, and 50% of relative humidity.

[0273] [test methods]

[0274] (1) Viscosity average molecular weight (hereinafter also referred to as "Mv".)

[0275] Based on ASRM-D4020, the intrinsic viscosity [η] at 135° C. using a decalin solvent was obtained, and Mv of polyethylene was calculated by the following formula.

[0276] [η]=0.00068×Mv 0.67

[0277] In addition, Mv of polypropylene was calculated|required by the following formula.

[0278] [η]=1.10×Mv 0.80

[0279] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com