Particle material discharging device through swing rod drive

A blanking device and swing rod technology, applied in the field of feeder for pig raising, can solve the problems of difficult control of feeding volume, waste of feed, fast feeding speed, etc., so as to prevent feed pollution, feed waste, and slow feeding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

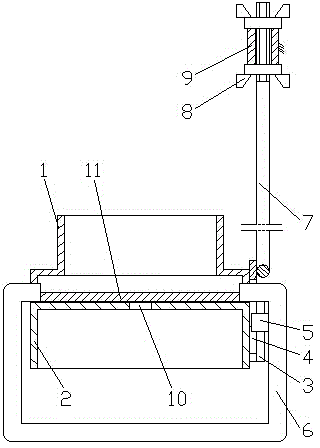

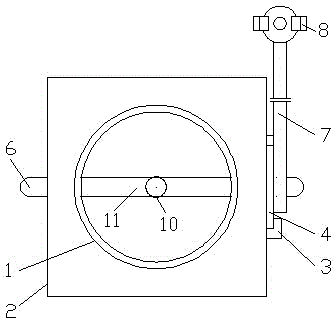

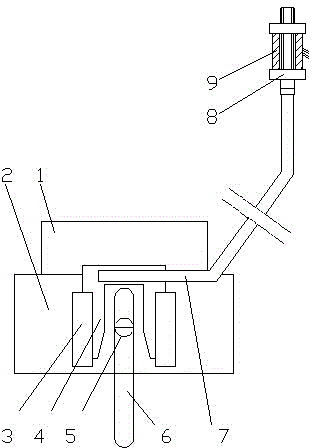

[0015] As shown in the figure, a swing rod drives the granular material blanking device. The machine base 2 is in the shape of a square cover. A blanking hole 10 is provided in the center of the square cover, and a strip-shaped blanking control is provided on the blanking hole 10. The door 11, the two ends of the blanking control door 11 are connected with the swing rod 6, the blanking control door 11 and the swing rod 6 form a rectangular ring, and the upper corner of the swing rod 6 is provided with a positioning pin 5, and on the outer wall of the machine base 2 There are two guide grooves 3 on the top, and a control slider 4 is installed in the two guide grooves 3. The control slider 4 is provided with an opening slot with an opening downward. Located in the opening slot on the control slider 4, the lower end of the control slider adjustment rod 7 is connected with the control slider 4, and the upper end of the control slider adjustment rod 7 is connected with the adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com