Multistage spillage preventing device of soybean milk maker

A soymilk machine and anti-overflow technology, which is applied to beverage preparation devices, milk replacers, household appliances, etc., can solve the problems of difficulty in synchronizing foam, aggravating overflow, and irreconcilability, and can increase local air pressure, reduce foam generation, and prevent bubbles. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

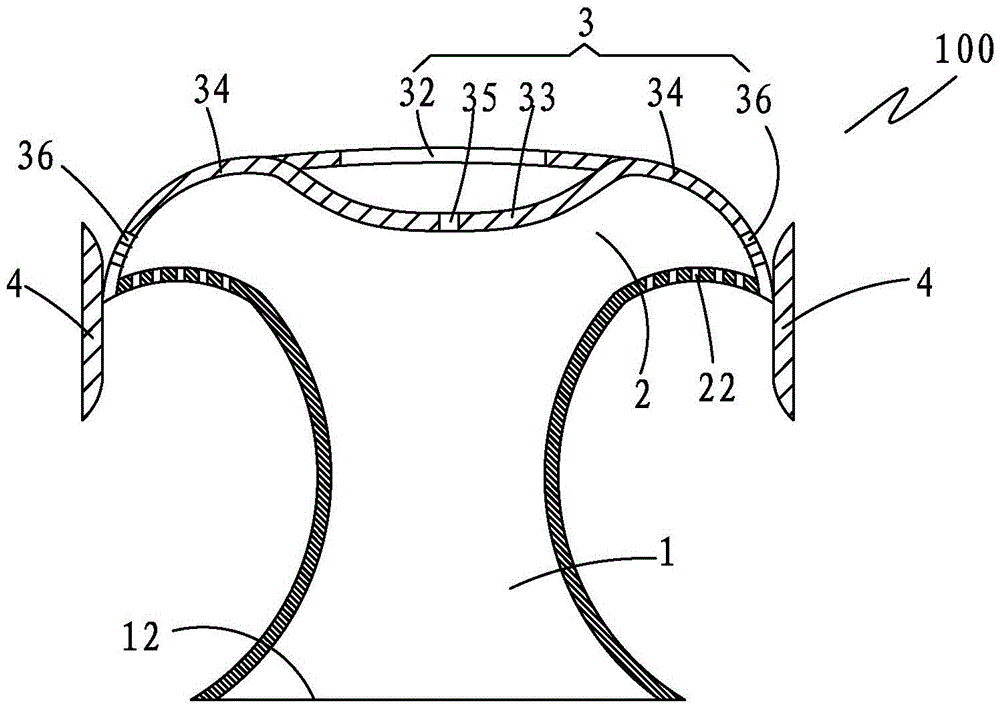

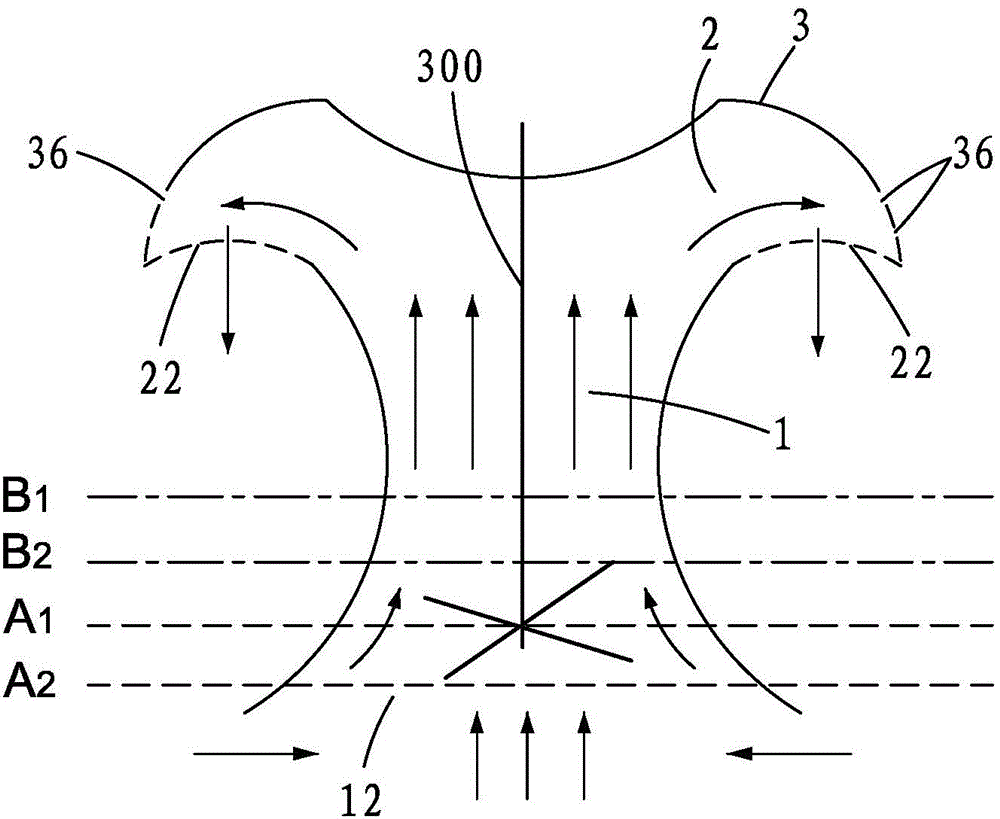

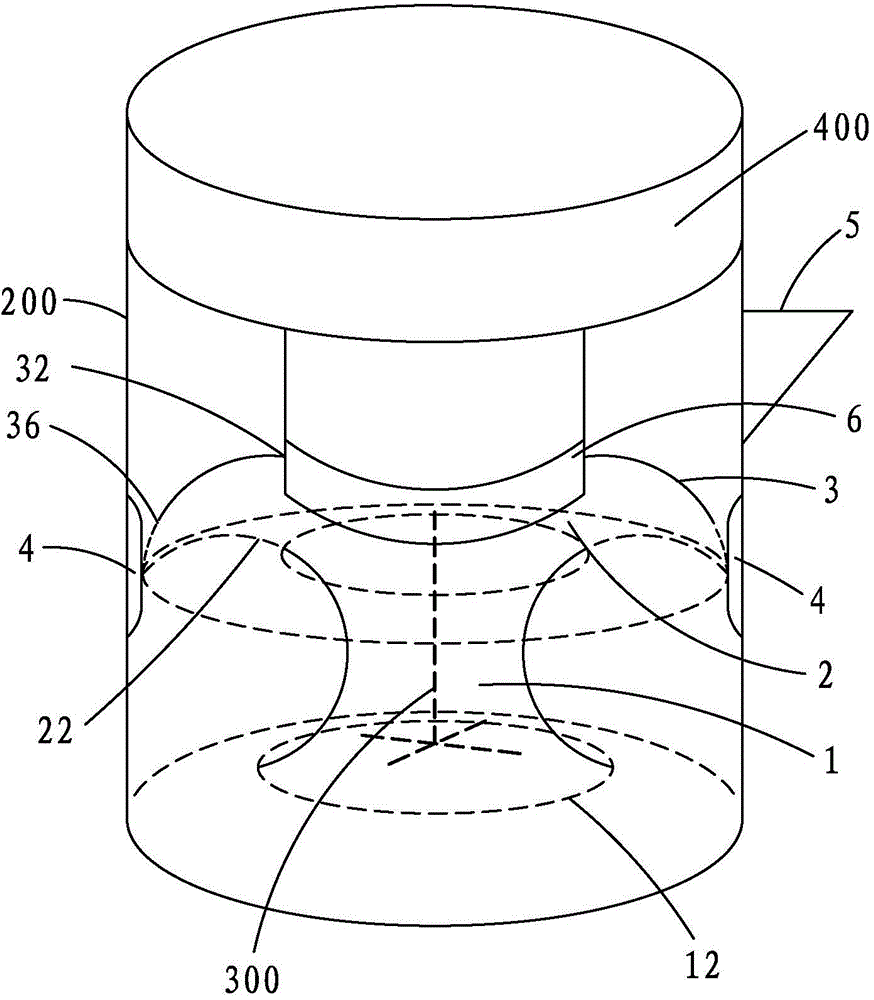

[0025] Such as Figure 1 to Figure 3 As shown, the multiple anti-overflow device 100 of the soybean milk machine of the present invention includes an upward channel 1, a diversion guide channel 2, an anti-overflow arched top 3, a smooth rail for pressure relief on the cup wall 4, and a gas overflow port 5; Track 6.

[0026] The upward channel 1 is vertically arranged in the milk cooking cup 200, the grinding cutter head 300 of the soybean milk machine is arranged in the upward channel 1, and the bottom opening of the upward channel 1 is the upward inlet 12 of soybean milk, and the top is connected to the split flow Guide channel 2; the inner diameter of the upward channel 1 gradually decreases from bottom to top, so that the soybean milk has enough pressure to continue upward in the middle of the upward channel 1, and reaches the diversion guide channel 2, and the upward inlet 12 of the soybean milk is smooth The transitional bell mouth makes the entrance relatively wide, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com