Cleaning mechanism for cleaning filtering net by left-right swinging on solid-liquid separator

A solid-liquid separator, left and right swing technology, applied in the direction of filtration separation, separation method, fixed filter filter, etc., can solve the problems of low degree of automation, filter blockage, low efficiency, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

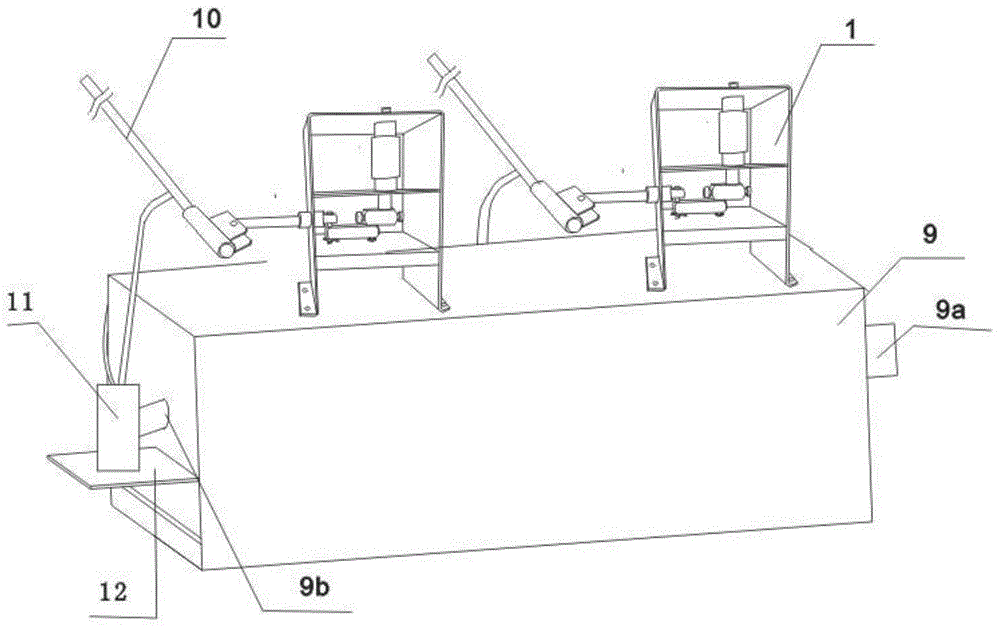

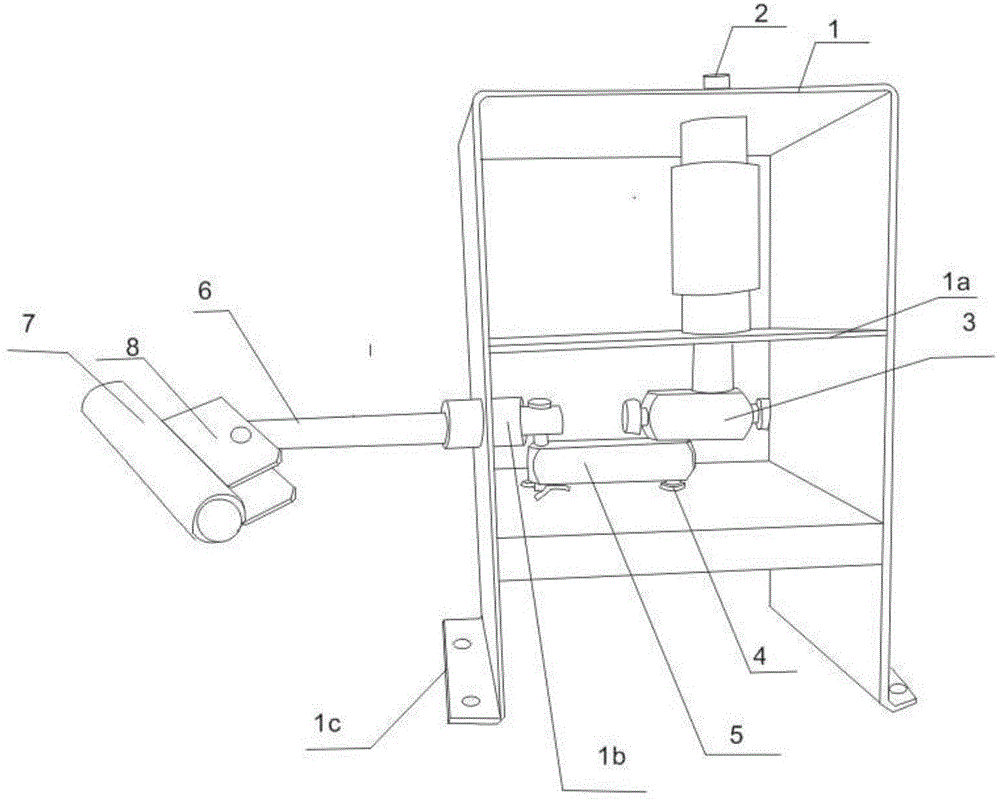

[0020] Such as Figure 1-2 As shown: the cleaning mechanism of the solid-liquid separator of the present invention that swings left and right to clean the filter screen includes a box body 1, a vertical shaft 2, a first connecting rod 3, a pin 4, a second connecting rod 5, a connecting shaft 6, and a connecting shaft sleeve Tube 1b, transverse plate 1a, gun shaft fixing tube 7, installation part 1c, connecting plate 8, water tank 9, high pressure water gun 10, water pump 11 and water pump mounting bracket 12 and other components.

[0021] The water tank 9 is installed in the cabinet of the solid-liquid separator, and the water tank 9 is provided with a water inlet 9a and a water outlet 9b, preferably the water inlet 9a and the water outlet 9b are located on the opposite side, and the water outlet 9b passes through the inlet of the water pump 11 and the high-pressure water gun 10 Link to each other, the back side of water tank 9 is provided with water pump mounting bracket 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com