A device for collecting and filtering metal dust vapor

A technology for metal dust and filter devices, which is used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of equipment damage, low metal dust removal efficiency, high noise, etc., to increase the dust removal area and increase the side The effect of moving to the range and reducing the running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

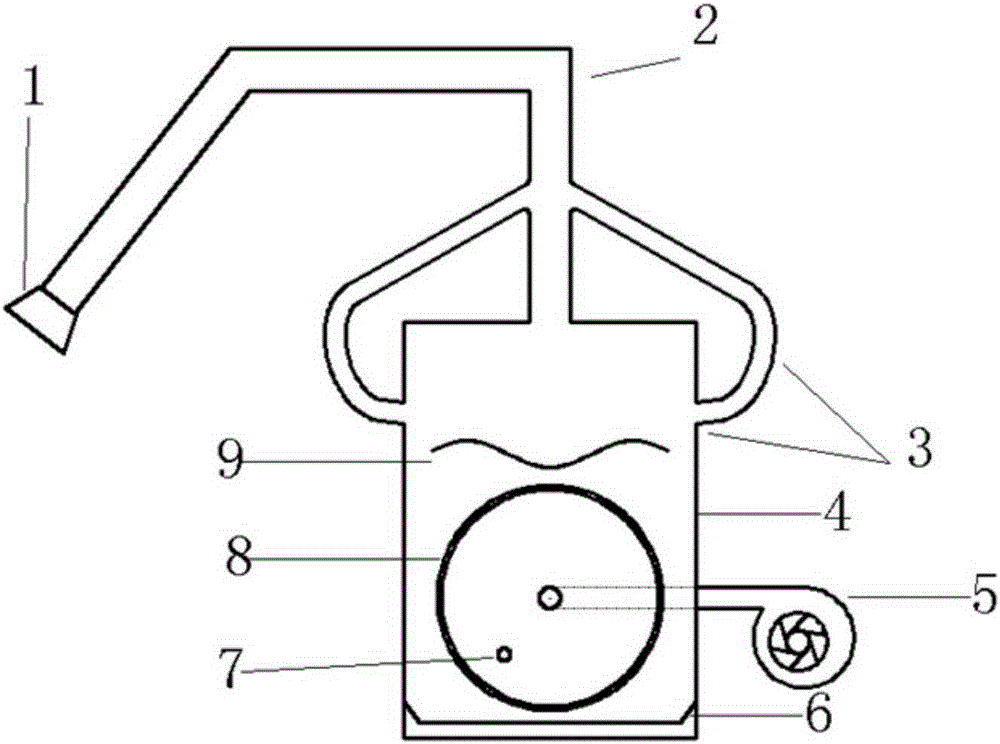

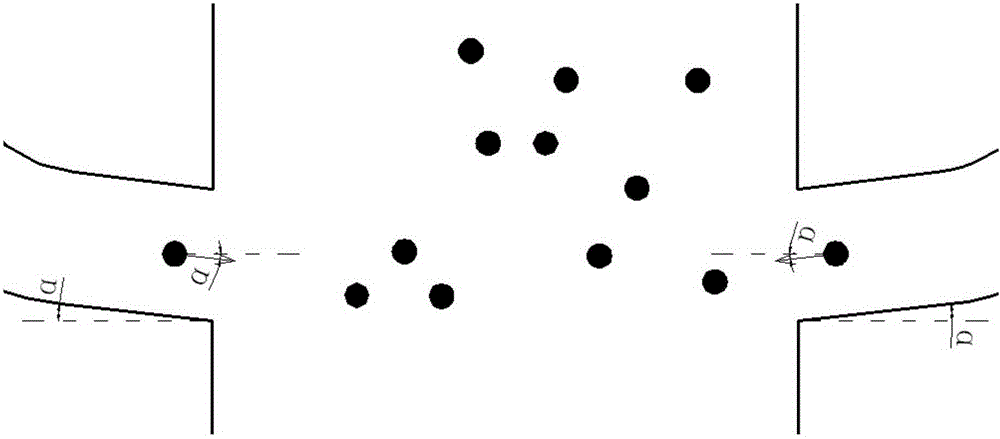

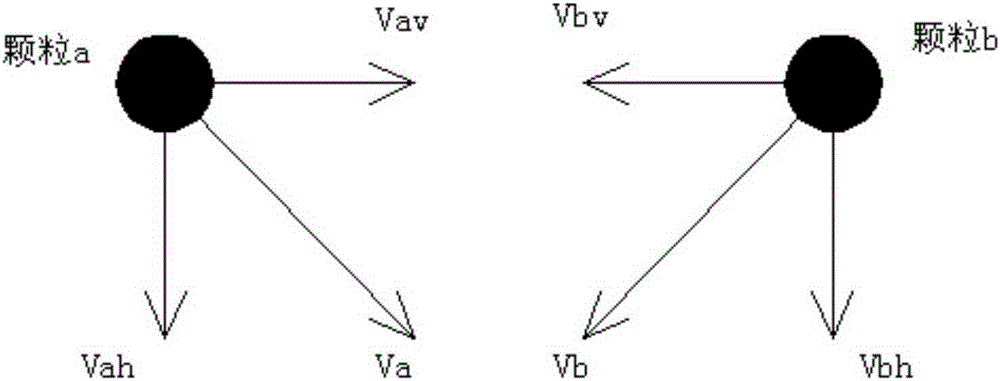

[0022] Such as figure 1 As shown, a device for collecting and filtering metal dust vapor, including a trumpet-shaped collection port 1, a suspension arm feeder 2, a side air inlet 3, a dust removal chamber 4, a negative pressure fan 5, and a gas shock hammer 7 , high-efficiency dust removal cylinder 8 and streamlined spoiler 9. The fan 5 provides a negative pressure environment for the whole equipment, so that the dust-laden gas enters the interior of the dust removal chamber 4 through the trumpet-shaped collection port 1 through the suspension arm 2 and the side wind inlet 3, and the air entering from the suspension arm 2 and the side wind inlet 3 The dusty gas intersects with each other, and the metal particles inside collide, which reduces the speed of the dust particles, and then the dusty gas continues to hit the streamlined spoiler 9, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com