Stirring-type passivation device

A stirring type, passivation tank technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow passivation time, electrostatic spraying film peeling off, uneven thickness of passivation film, etc. To achieve the effect of speeding up the passivation speed and uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

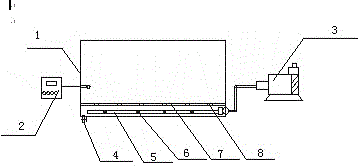

[0012] attached by figure 1 It can be seen that the present invention includes a passivation tank 1, the bottom of the passivation tank 1 is provided with a partition 7, and the partition 7 is provided with a plurality of through holes 8, and the partition 7 separates the passivation tank 1 into upper and lower parts. Two spaces, the bottom space between the partition plate 7 and the passivation tank 1 is provided with an air supply pipe 5, the air supply pipe 5 is connected with the blower 3, and several exhaust holes 6 are arranged on the air supply pipe 5 . The above-mentioned passivation tank 1 is also provided with a concentration controller 2 for monitoring and controlling the concentration of the liquid medicine in the tank. A sewage pipe 4 is provided at the bottom of the above-mentioned passivation tank 1 .

[0013] When in use, turn on the blower 3 and carry out air agitation to the passivation tank 1 to make the passivation solution in the tank flow, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com