A kind of preparation method of high-efficiency crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high cost, many precious metals, and weak efficiency improvement effect, so as to reduce the use of precious metals, increase absorption and utilization, and improve battery conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

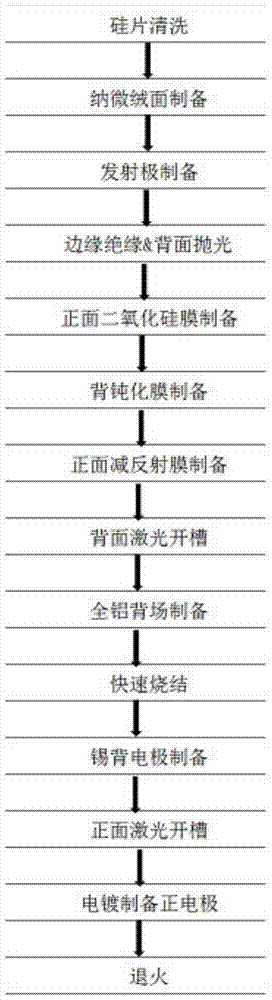

Method used

Image

Examples

Embodiment 1

[0040] Example 1: (1) Clean the silicon wafer; (2) Prepare nano-micro composite suede on the front of the silicon wafer by reactive ion etching, and then use a mixed solution of BOE, hydrogen peroxide and DI water to clean the surface of the silicon wafer; (3) Use The emitter is prepared by the diffusion process, and the square resistance of the emitter is 95 ohms; (4) The front side of the silicon wafer is protected by a water film, and the back side is directly in contact with the corrosion chemical, the edge PN junction and the surface phospho-silicate glass are removed, and the back side is polished at the same time. The reflectivity is controlled at 30; (5) Ozone oxidation is used to grow a layer of silicon dioxide on the surface of the silicon wafer with a thickness of 2nm; (6) The plasma-enhanced chemical vapor deposition method (ie PECVD) is used to prepare three Aluminum oxide + silicon nitride composite film, in which the thickness of aluminum oxide is 5 nm, and the t...

Embodiment 2

[0041]Example 2: (1) Clean the silicon wafer; (2) Prepare nano-micro composite suede on the front of the silicon wafer by metal-assisted chemical etching, and then use a mixed solution of BOE, hydrogen peroxide and DI water to clean the surface of the silicon wafer; (3) The emitter is prepared by the ion implantation process, and the square resistance of the emitter is 100 ohms; (4) The front side of the silicon wafer is protected by a water film, and the back side is directly in contact with corrosive chemicals to remove the edge PN junction and surface phospho-silicate glass, and the back side is polished at the same time. After polishing, the reflectivity is controlled at 33; (5) A layer of silicon dioxide is grown on the surface of the silicon wafer with a thickness of 10 nm by thermal oxidation; Al2O3, with a thickness of 25 nm, and after low-temperature annealing, PECVD was used to prepare silicon nitride, and superimposed on Al2O3, the thickness of silicon nitride was 15...

Embodiment 3

[0042] Example 3: (1) Clean the silicon wafer; (2) Prepare nano-micro composite suede on the front of the silicon wafer by metal-assisted chemical etching, and then use a mixed solution of BOE, hydrogen peroxide and DI water to clean the surface of the silicon wafer; (3) The emitter is prepared by the ion implantation process, and the square resistance of the emitter is 95 ohms; (4) The front side of the silicon wafer is protected by a water film, and the back side is directly in contact with corrosion chemicals to remove the edge PN junction and surface phospho-silicate glass, and the back side is polished at the same time. After polishing, the reflectivity is controlled at 30; (5) A layer of silicon dioxide is grown on the surface of the silicon wafer by thermal oxidation method, with a thickness of 2nm; (6) Al2O3 is prepared on the back of the silicon wafer by ALD method, with a thickness of 5 nm, and then after low-temperature annealing, silicon nitride was prepared by PECV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com