A hydrogen-rich PECVD process method for enhancing the hydrogen passivation ability of solar cells

A solar cell and hydrogen passivation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of restricting the photoelectric conversion efficiency of crystalline silicon solar cells, impurity cannot be completely removed, and carrier life is reduced, etc. and control, high practical value, optimized effect of bulk passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

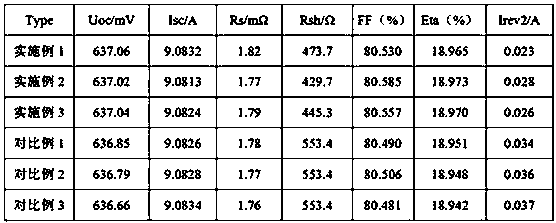

Examples

Embodiment 1

[0027] The present invention achieves the above object by providing a hydrogen-rich PECVD process that enhances the hydrogen passivation ability of solar cells, and is characterized in that: through normal NH 3 After the pretreatment, the first and second layers of coating, the H 2 plasma deposition.

[0028] A hydrogen-rich PECVD process for enhancing the hydrogen passivation ability of solar cells, characterized in that: the NH 3 Pretreatment is to use ammonia gas to pretreat the surface of the silicon wafer after high-frequency ionization;

[0029] where NH 3 The pre-cleaning parameters were set as follows: deposition temperature 400 °C, power 4500 W, ammonia gas flow rate 7 slm, pressure 1700 mTor, duty cycle 4:40 ms, cleaning time 10 s.

[0030] The first layer of coating film described in it utilizes setting pressure and temperature, passes through silane (SiH 4 ) and ammonia (NH 3 ), after high-frequency ionization, it is deposited on the surface of the silicon waf...

Embodiment 2

[0045] All the other are specifically with embodiment 1

[0046] A hydrogen-rich PECVD process that enhances the hydrogen passivation ability of solar cells is completed through the following steps:

[0047] (1) NH 3 Pretreatment: deposition temperature 415 ℃, power 5500 W, ammonia gas flow rate 6 slm, pressure 1750 mTor, duty cycle 4:40 ms, cleaning time 15 s;

[0048] (2) The first layer of coating: deposition temperature 430 ℃, power 6800 W, ammonia flow rate 4.2 slm, silane flow rate 1100 sccm, pressure 1600 mTor, duty cycle 5:50 ms, deposition time 140 s; The ratio is controlled at 2.28, and the film thickness is controlled at 20 nm;

[0049] (3) The second layer of coating: the deposition temperature is 445 ℃, the deposition power is 7400 W, the duty cycle is 5:50 ms, the pressure is 1550 mTor, the deposition time is 470 s. The flow rate achieves a negative rate of uniform decline; among them, the initial flow rate of ammonia is 3.8 slm, the flow rate at the end of de...

Embodiment 3

[0058] All the other are specifically with embodiment 1

[0059] A hydrogen-rich PECVD process that enhances the hydrogen passivation ability of solar cells is completed through the following steps:

[0060] (1) NH 3 Pretreatment: deposition temperature 430 ℃, power 5000 W, ammonia gas flow rate 6.5 slm, pressure 1650 mTor, duty cycle 4:40 ms, cleaning time 20 s;

[0061] (2) The first layer of coating: deposition temperature 460 ℃, power 6500 W, ammonia flow rate 4.0 slm, silane flow rate 1000 sccm, pressure 1650 mTor, duty cycle 5:50 ms, deposition time 100 s; The ratio is controlled at 2.25, and the film thickness is controlled at 15 nm;

[0062] (3) The second layer coating: deposition temperature is 430 ℃, deposition power is 7800 W, duty cycle is 5:50 ms, pressure is 1600 mTor, deposition time is 450 s. During this deposition time, the flow of ammonia gas achieves a positive and uniform increase rate, and silane The flow rate achieves a negative rate of uniform declin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com