A kind of heat treatment method of tantalum powder

A heat treatment method, tantalum powder technology, applied in transportation and packaging, electrolytic capacitors, capacitors, etc., can solve the problems of high oxygen content of tantalum powder, large temperature difference, small temperature rise of tantalum powder, etc., to achieve uniform particle oxygen content, Oxygen content deviation is small and the effect of avoiding intense oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

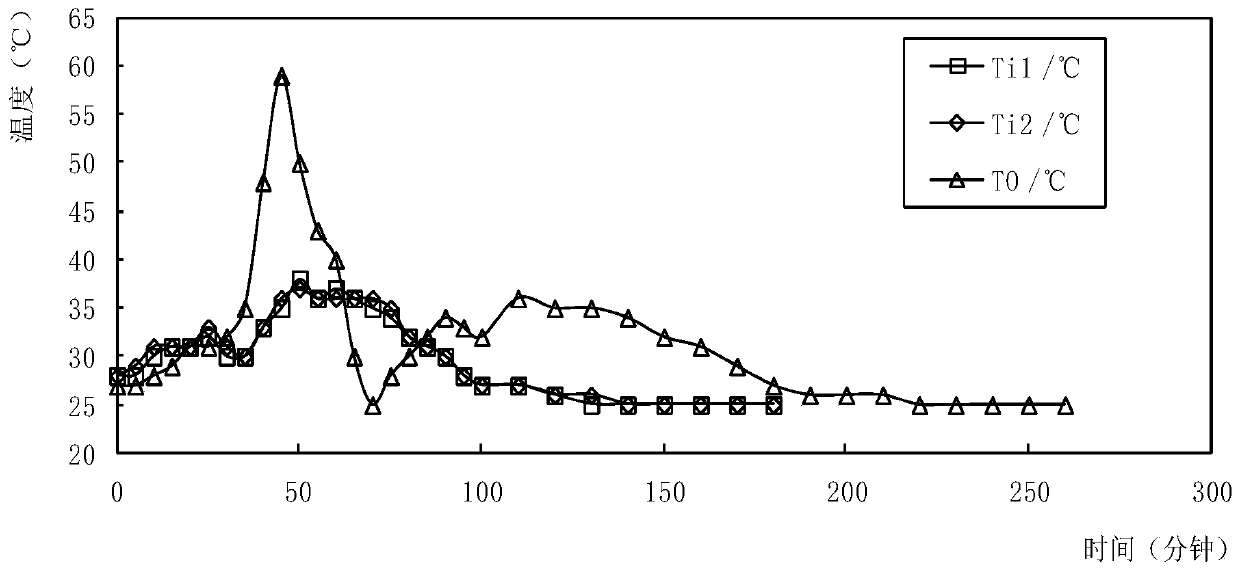

[0076] The tantalum powder prepared by reducing potassium fluorotantalate with sodium is washed with water, pickled with acid, washed with water and filtered, and the specific surface area after drying is 0.61m 2 / g, the oxygen content is 3050ppm, and the tantalum powder that nitrogen content is 80ppm is packed into tantalum crucible 4 lis, and the above-mentioned crucible 4 that tantalum powder is housed is packed again such as Figure 5 The heat treatment is carried out in the shown vacuum heat treatment furnace. The heat treatment furnace has a furnace shell 1 with a cooling water jacket 91 and a cooling water outlet 92. The inner and outer layers of the furnace are insulation screens composed of multi-layer heat-resistant metals. 2. Inside the insulation screen is a heater 3 made of high-temperature-resistant metals such as tantalum. Three layers of crucibles 4 are placed in the heater. row, 3 in each row, a total of 27 tantalum crucibles, a bendable thermocouple T i1 51 ...

Embodiment 2

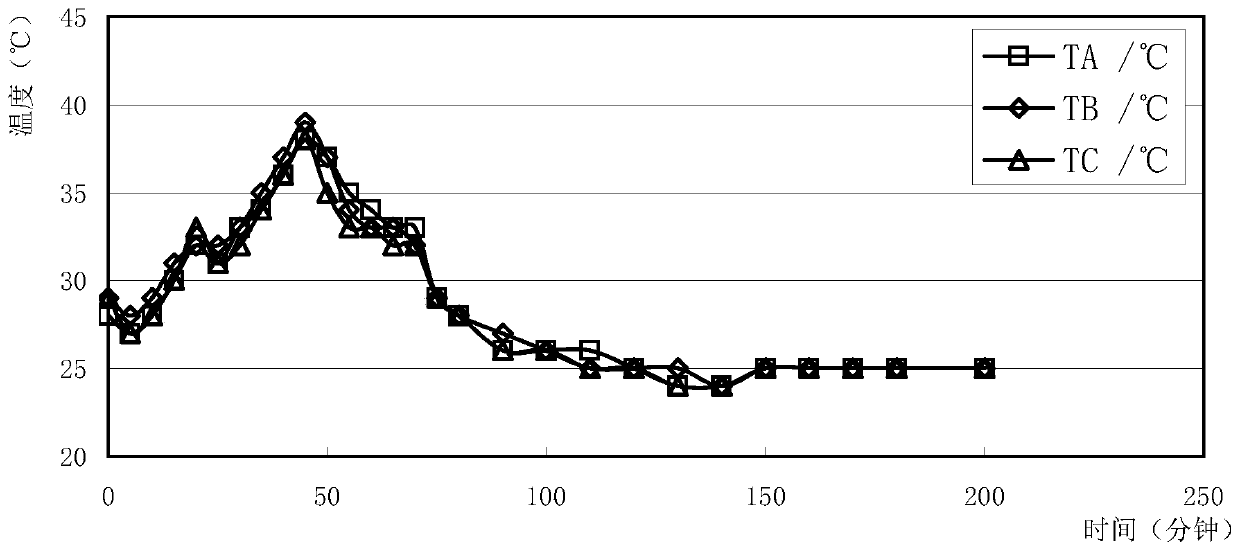

[0084] use as Figure 6 In the passivation device shown, the specific surface area obtained after heat treatment of 130kg is 0.428m 2 / g, tantalum powder with an oxygen content of 4010ppm and a nitrogen content of 110ppm, add 2080 grams of magnesium powder, mix the magnesium powder and tantalum powder evenly, put them into 11 tantalum crucibles 17, and put 3 bendable thermocouples 3A , 3B and 3C are respectively placed on the tantalum powder 16 in the center of the bottom layer of the tantalum crucible, the sixth layer of the tantalum crucible and the top layer of the tantalum crucible (the three thermocouples of 3A, 3B and 3C are distributed in the reactor On a concentric circle of the outer circle of the cover, there is an included angle of about 10° to 15° between 3A and 3B and 3B and 3C, Figure 6 The middle thermocouples 3A, 3B and 3C just mean that three thermocouples are placed in tantalum crucibles of different heights from the reactor cover downwards), and the materi...

Embodiment 3

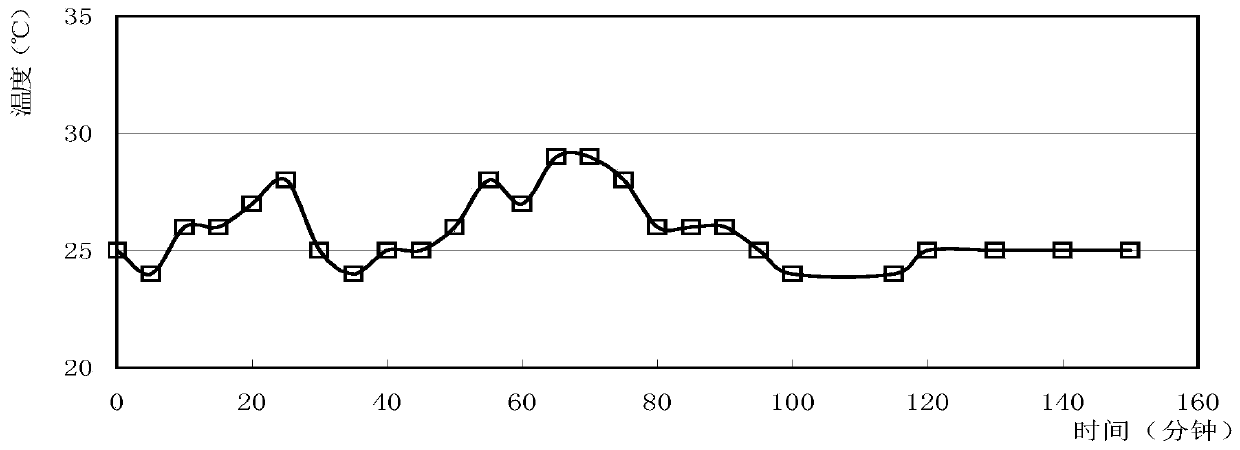

[0094]The oxygen content that has carried out deoxidation treatment with embodiment 2 is 2000ppm, and specific surface area is 0.42m 2 / g of tantalum powder is used as the raw material of the capacitor anode, and 0.21mm tantalum wire is used as the lead wire to bury it in the tantalum powder. Each anode block uses 1.245 grams of tantalum powder and presses it into a cylinder with a diameter of 6 mm and a thickness of 8 mm. The density of tantalum pressing is about 5.5g / cm 3 Put the compact into a tantalum crucible, place a thermocouple on the tantalum anode compact, put the tantalum compact into a vacuum sintering furnace for sintering, and evacuate until the vacuum degree reaches 1×10 -5 Torr, heat up to 1480°C for sintering for 20 minutes, then power off to cool down to 25°C. Since the sintered tantalum block is relatively large, it is difficult to dissipate the internal heat during passivation. The passivation treatment is carried out with argon and air cooled to about -5°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com