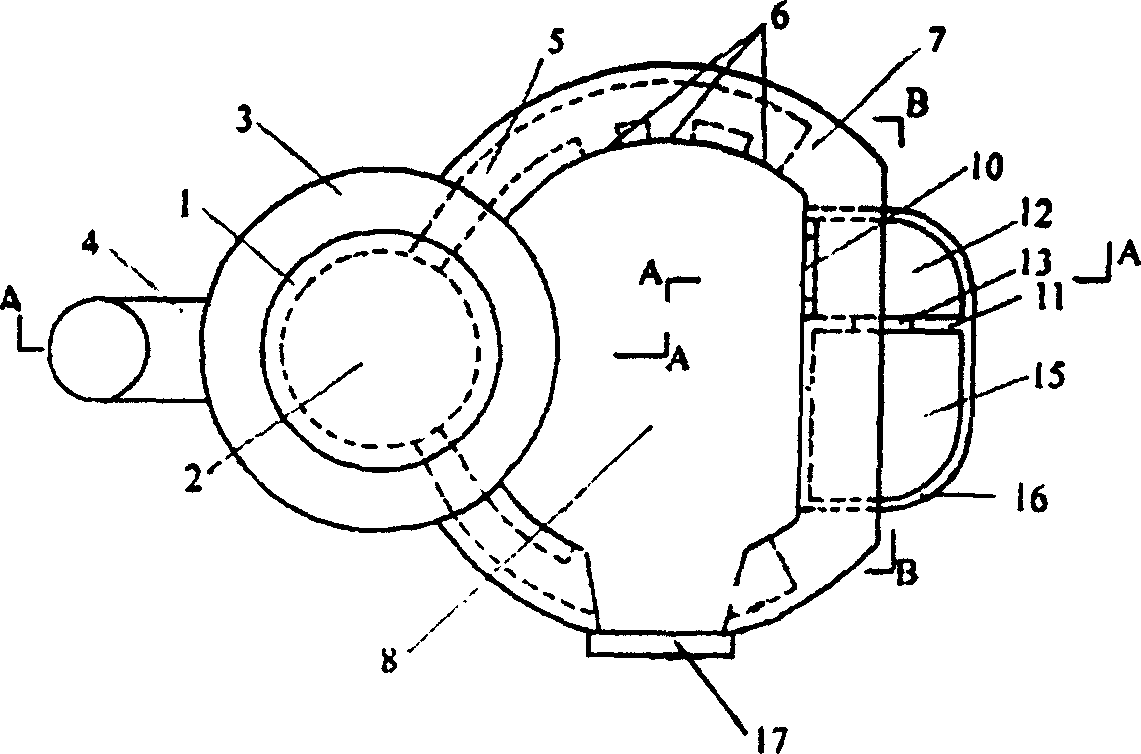

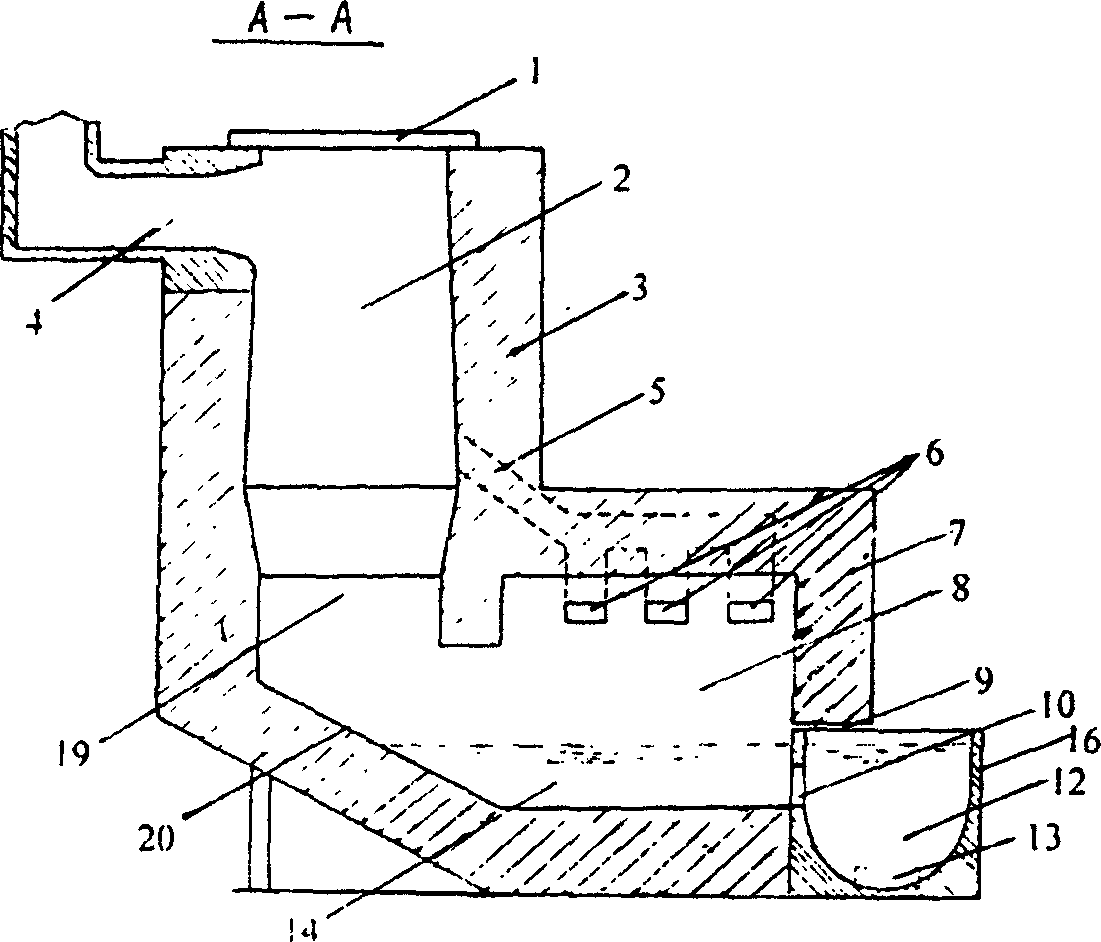

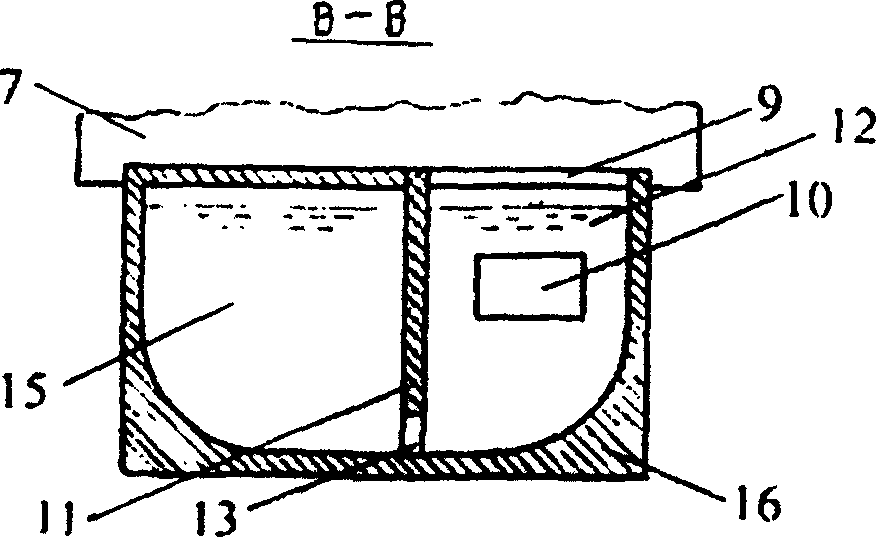

Energy-saving continuous aluminum alloy melting-refining furnace

An aluminum alloy, energy-saving technology, applied in the field of continuous aluminum alloy melting-refining device, to achieve the effects of convenient operation, uniform temperature and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The existing continuous aluminum melting furnace melts 500 kilograms of aluminum per hour. Two heavy oil burners are installed in the overheating area, and the fuel consumption is 20 kg per hour. Three 30 kW resistance furnaces (each containing 500 kg of aluminum water) are used to operate simultaneously. After adjusting the temperature of the aluminum liquid to 700 ° C, the aluminum liquid is degassed with nitrogen. After slag removal and standing still, the blanks of auto parts are poured. This operation takes about 3 hours. The power consumption per kilogram of aluminum alloy is about 0.20 degrees. After changing the structure of the present invention, it can guarantee to obtain the suitable temperature of molten aluminum (see Table 2), thereby canceling the resistance furnace, and saving 200 kwh of electricity per ton of molten aluminum.

[0031] Table 2 Temperature of molten aluminum in different parts ℃

[0032] Superheating zone Degassing tank P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com