Fluidized electric separation device

A fluidization and electro-separation technology, which is applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve the problems of complex structure of electro-separation equipment and insufficient charging of materials, and achieves good separation effect and high charging efficiency. The effect of good electrical effect and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

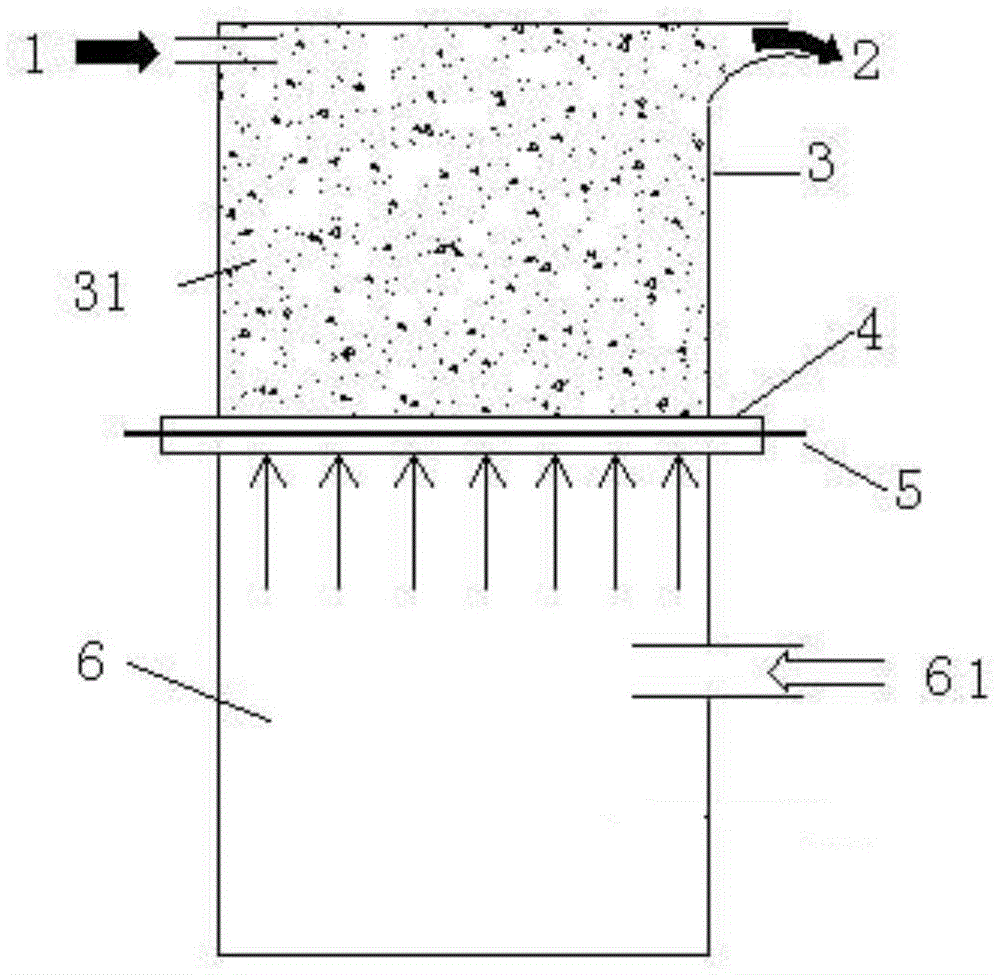

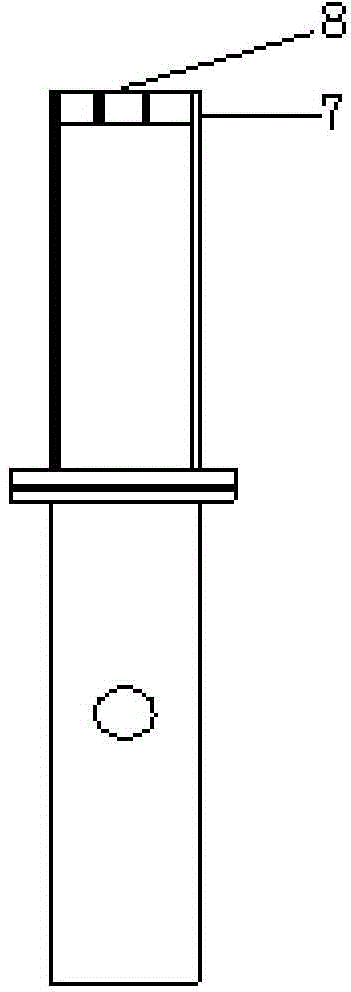

[0024] The powder material is sent into the fluidized bed 31 of the fluidized electric separator body 3 through the feeder through the feed port, the air supply system 61 is opened, and a fan is used to supply air to the fluidized electric separator body 3, and the wind force is from the supply The air system 61 enters the air chamber 6 through the pipe, and then enters the fluidized bed 31 through the air distribution plate 5, and supplies air to the inside of the fluidized bed 31 to fluidize the material. The air distribution plate 5 adopts an orifice plate with air permeability The material, which can be textile or perforated ceramic plate, can be determined by yourself.

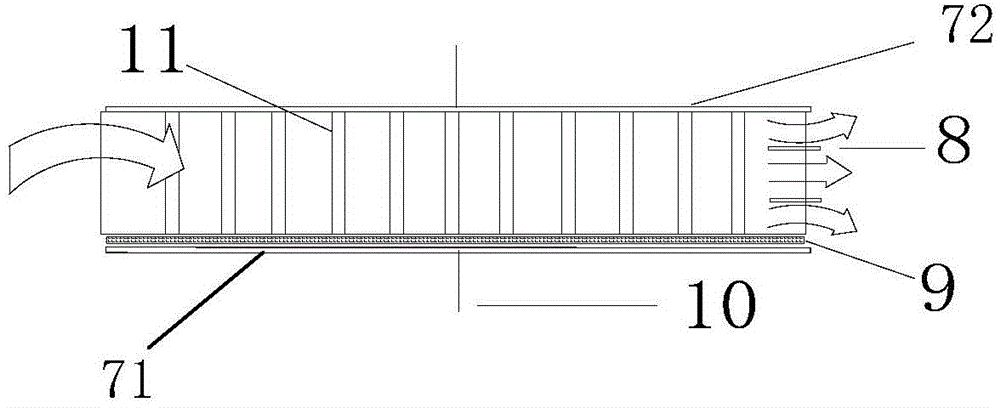

[0025] The front and rear side inner walls of the fluidized bed 31 are conductive front electrode plates 71 and rear electrode plates 72, the front electrode plates 71 and the rear electrode plates 72 are conductive metal material plates, and the front and rear electrode plates 71 , 72 electrode plates ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com