Electronic photographic developer and method for forming image

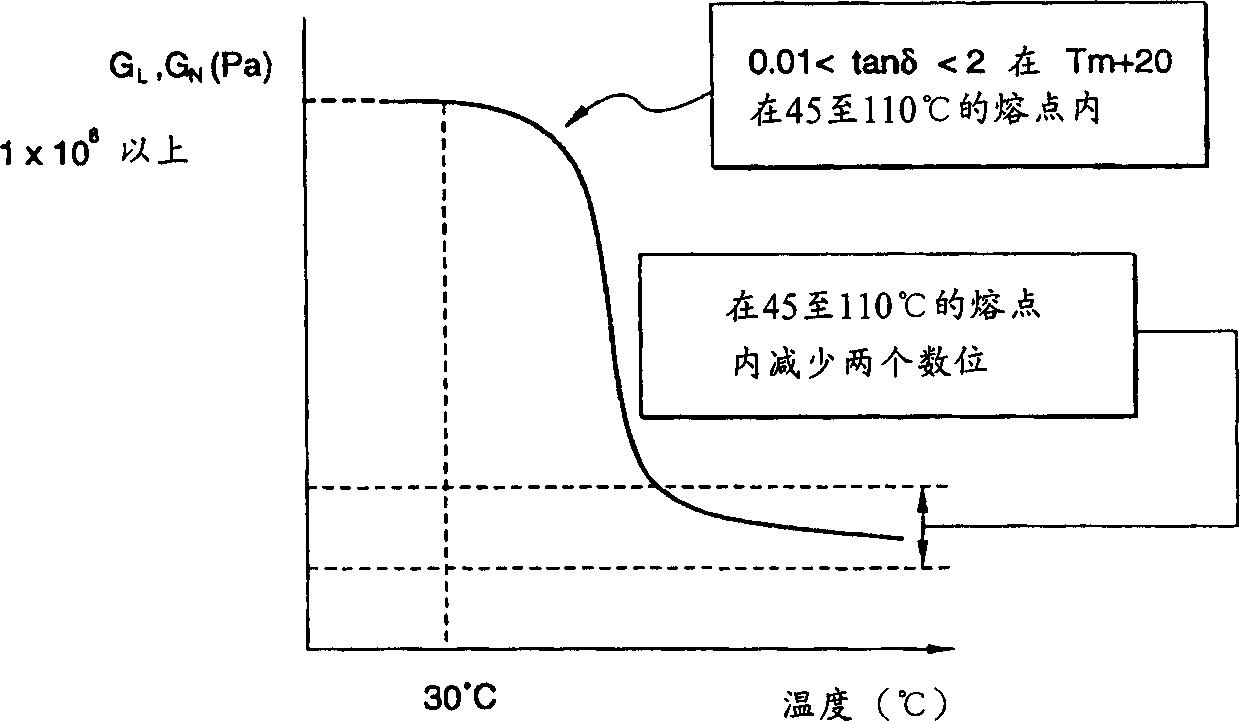

A technology for electrophotography and developer, applied in the direction of developer, electrography, optics, etc., can solve the problems of toner transfer charge, difficult charge of crystalline resin, etc., to achieve improved charging performance, good charging performance, image Excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] Synthesis of Crystalline Polyester Resin (1)

[0173] 17.4 parts by weight of 1,10-decanediol, 2.2 parts by weight of sodium dimethyl sulfophthalate, 10 parts by weight of dimethyl sulfite and 0.03 parts by weight of dibutyltin oxide as a catalyst were placed In the heated three-necked flask, the air in the flask was replaced with nitrogen by a decompression operation to form an inert atmosphere, followed by mechanical stirring at 180° C. for 3 hours. Dimethyl sulfoxide was distilled off under reduced pressure, and 26.5 parts by weight of dimethyl dodecanedioate was added thereto, followed by stirring at 180° C. for 1 hour.

[0174] Thereafter, the temperature was gradually increased to 220°C under reduced pressure, followed by stirring for 30 minutes. When the contents of the flask were in a viscous state, they were then cooled with air to terminate the reaction to synthesize 36 parts by weight of crystalline polyester resin (1).

[0175] The resulting crystalline po...

Embodiment 2

[0240] Synthesis of Crystalline Polyester Resin (2)

[0241] 124 parts by weight of ethylene glycol, 22.2 parts by weight of 5-sulfodimethylsodium phthalate, 213 parts by weight of dimethyl sebacate and 0.3 parts by weight of dibutyltin oxide as a catalyst were placed in the In the heated three-necked flask, the air in the flask was replaced with nitrogen by a decompression operation to form an inert atmosphere, followed by stirring at 180° C. for 5 hours with mechanical stirring.

[0242] Thereafter, the temperature was gradually increased to 220°C under reduced pressure, followed by stirring for 2 hours. When the contents of the flask were viscous, they were then cooled with air to terminate the reaction to synthesize 220 parts by weight of crystalline polyester resin (2).

[0243] The obtained crystalline polyester resin (2) was measured for molecular weight by gel permeation chromatography (GPC) (polystyrene standard), and it had a weight average molecular weight (Mw) of ...

Embodiment 3

[0263] Preparation of carrier (2)

[0264]A film-forming solution obtained by mixing a carbon dispersion liquid and 0.63 parts by weight of an 80% by weight trifunctional isocyanate (Takenate D110N, produced by Takeda Chemical Co., Ltd.) in ethyl acetate, and 100 parts by weight of Mn-Mg-Sr iron oxide Bulk particles (average particle diameter: 35 µm) were placed in a kneader / coater and stirred at normal temperature for 5 minutes, and the solvent was distilled off by raising the temperature to 150°C under normal pressure, and the carbon dispersed The solution is by adding 0.12 parts by weight of carbon black (VXC-72, trade name, produced by Cabot Corporation) to 75% by weight of toluene / butyl acetate solution of 0.66 parts by weight of acrylic polyol and toluene of 1.25 parts by weight, It was then dispersed in a sand mill for 20 minutes. After a further 30 minutes of agitation, the heater was turned off and cooled to 50°C. The resulting coated support was sieved with a 75 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com