Preparation method of solvent resistant composite nanofiltration membrane

A composite nanofiltration membrane and solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of good compatibility of alcohol solvents and low solvent permeation flux, and achieve excellent stability performance, improved charging performance, and high permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

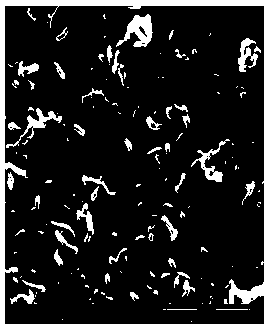

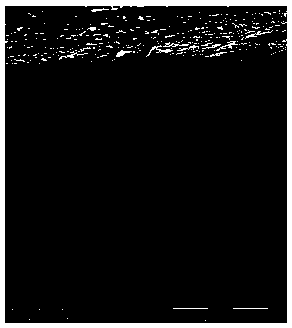

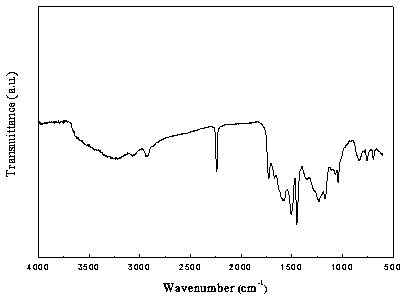

Image

Examples

Embodiment 1

[0029] Embodiment 1: This embodiment is a preparation method of a solvent-resistant composite nanofiltration membrane, specifically prepared according to the following steps.

[0030] 1. Preparation of ultrafiltration base membrane: firstly, the vacuum-dried polymer polyacrylonitrile was dissolved in dissolved nitrogen methyl pyrrolidone, and a polymer solution with a mass fraction of 18% was prepared.

[0031] Two, using the immersion-precipitation phase inversion method to make a polymer solution with a mass fraction of 18% into an ultrafiltration base membrane;

[0032] 3. Configure a sodium hydroxide solution with a mass concentration of 10% and a hydrochloric acid solution with a concentration of 0.1mol / L;

[0033] 4. Put the polyacrylonitrile-based film in sodium hydroxide solution, and react at 40 degrees Celsius for 30-120 minutes;

[0034] 5. After the reaction is over, put the membrane in deionized water for soaking and cleaning, and then place it in dilute hydrochl...

Embodiment 2

[0043] Example 2: Reference Example 1: The solvent described in step one is N-dimethylformamide, dimethylacetamide or dimethyl sulfoxide.

Embodiment 3

[0044] Embodiment 3: Referring to Embodiment 1 or 2: the mass fraction of aniline in the aniline-ethanol solution described in step 2 is 2% to 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com