A frame glue coating pre-curing device and method

A pre-curing and coating technology, which is applied to the device, coating, pre-treatment surface, etc. of the surface coating liquid. Easy to operate, increase product yield and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

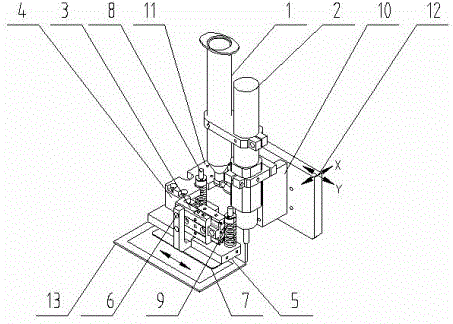

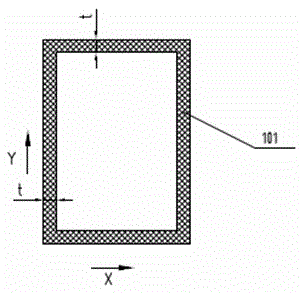

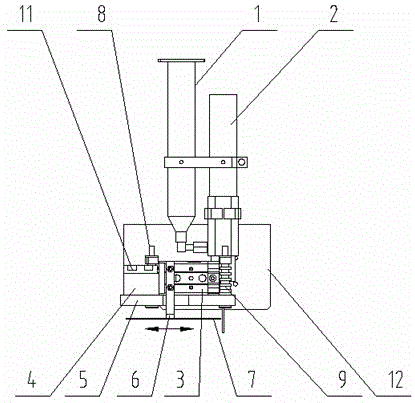

[0030] like figure 1 As shown in the figure, a sealant coating pre-curing device used in this method includes an X-direction ultraviolet light source 9, a Y-direction ultraviolet light source 8, a cylinder 3 and a dispensing valve 2, and the dispensing valve 2 is fixed in an X-direction ultraviolet light source , On the bracket plate 12 that moves in the Y direction, the X-direction ultraviolet light source 9, the Y-direction ultraviolet light source 8 and the cylinder 3 are installed on the fixing plate 5, the fixing plate 5 is connected with the bracket plate 12, and the lower part of the fixing plate 5 is provided. There is a shading plate 7, the shading plate 7 is fixed on the cylinder 3, and a light-transmitting hole is opened on the shading plate 7. The glue dispensing valve 2 is also connected with the glue storage cylinder 1 , the lower end of the glue dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com