Punching machine intelligent feeding-cropping mechanical arm

A manipulator and intelligent technology, applied in manipulators, program-controlled manipulators, forging/pressing/hammering machinery, etc., can solve the problems of manual crushing, disability, low production efficiency, etc., to avoid potential safety hazards, facilitate operation, reduce The effect of device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

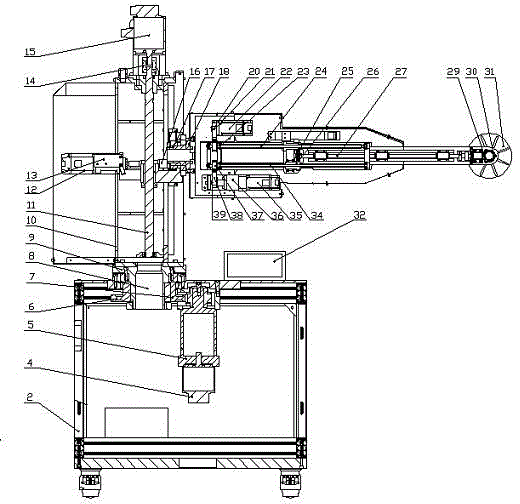

[0007] see figure 1 , The punch press intelligent loading and unloading manipulator provided by the present invention includes a swing arm movement mechanism, an up and down movement mechanism, a turning movement mechanism, a horizontal movement mechanism and an end rotation mechanism. The swing arm movement mechanism is provided with an upwardly extending 1-axis transmission shaft 8 and a 1-axis servo motor 4 for driving the rotation of the 1-axis transmission shaft. The 1-axis transmission shaft and the 1-axis servo motor are installed on the main engine on the frame 2; the up and down movement mechanism is provided with a vertical 2-axis ball screw 11 and a 2-axis servo motor 15 for driving the rotation of the 2-axis ball screw, the 2-axis ball screw and the 2 The axis servo motor is installed on the 2-axis frame 10, the 2-axis frame is located above the main frame and is fixedly connected with the 1-axis transmission shaft, when the 1-axis servo motor drives the 1-axis tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com