A system for casting alloys and a method for processing castings

A technology for casting alloys and alloys, which is applied to the system of casting alloys and the field of processing castings, can solve the problem that closed molds cannot be ultrasonically vibrated, and achieve the effects of increasing the nucleation rate, high mechanical properties, and broadening the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

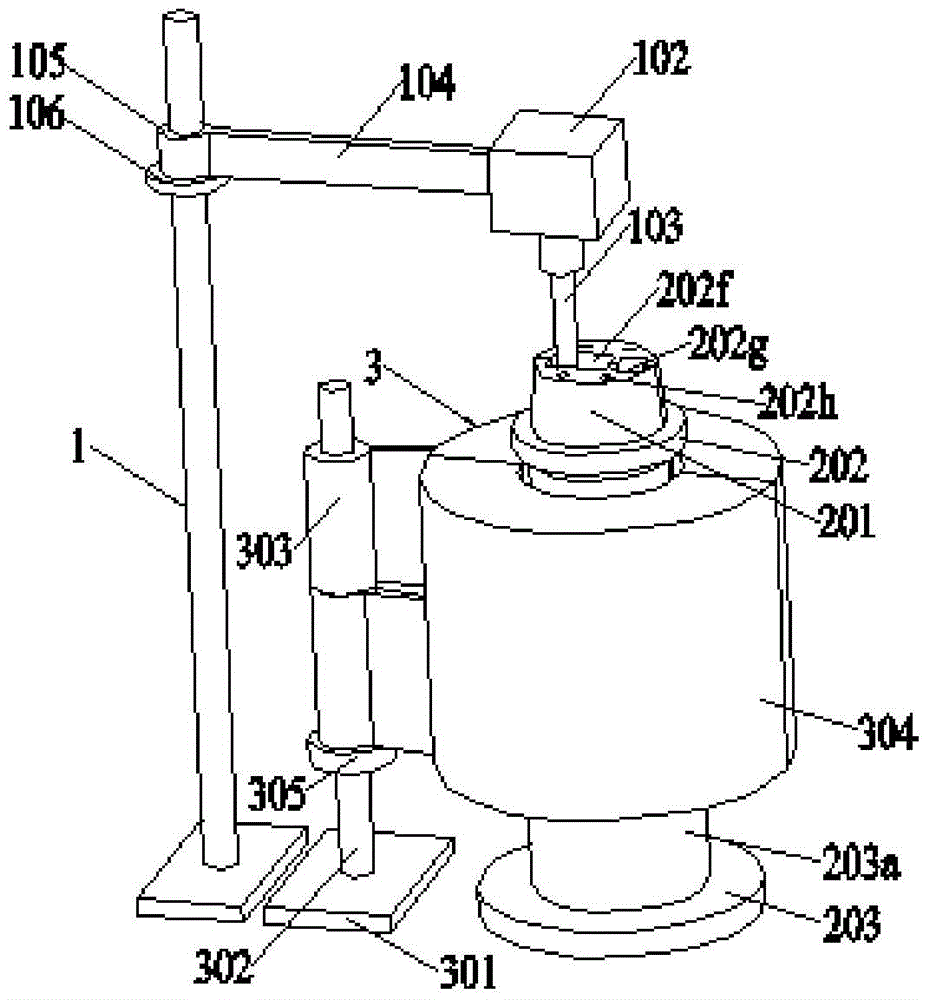

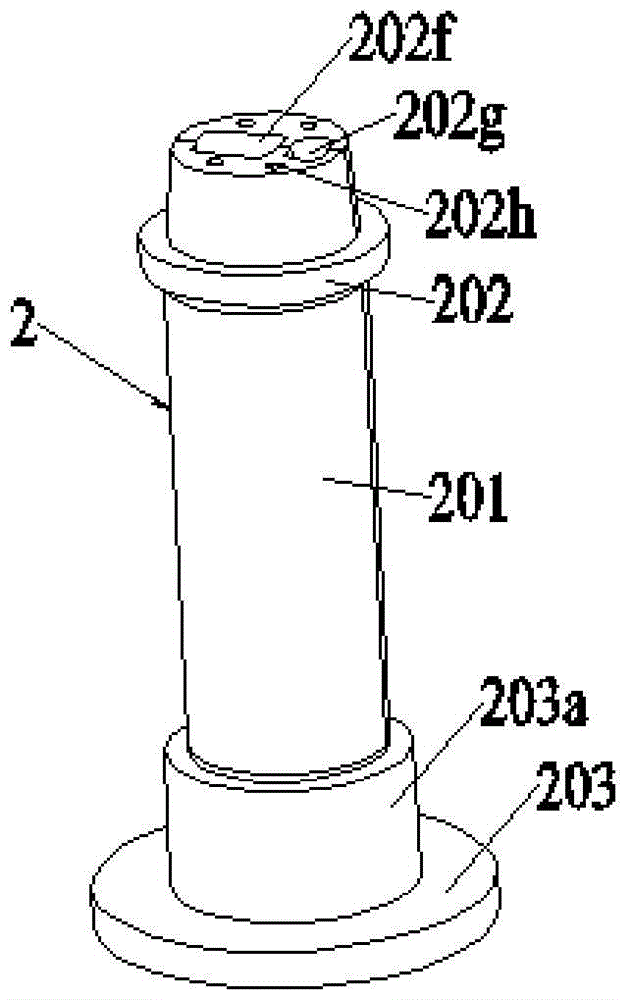

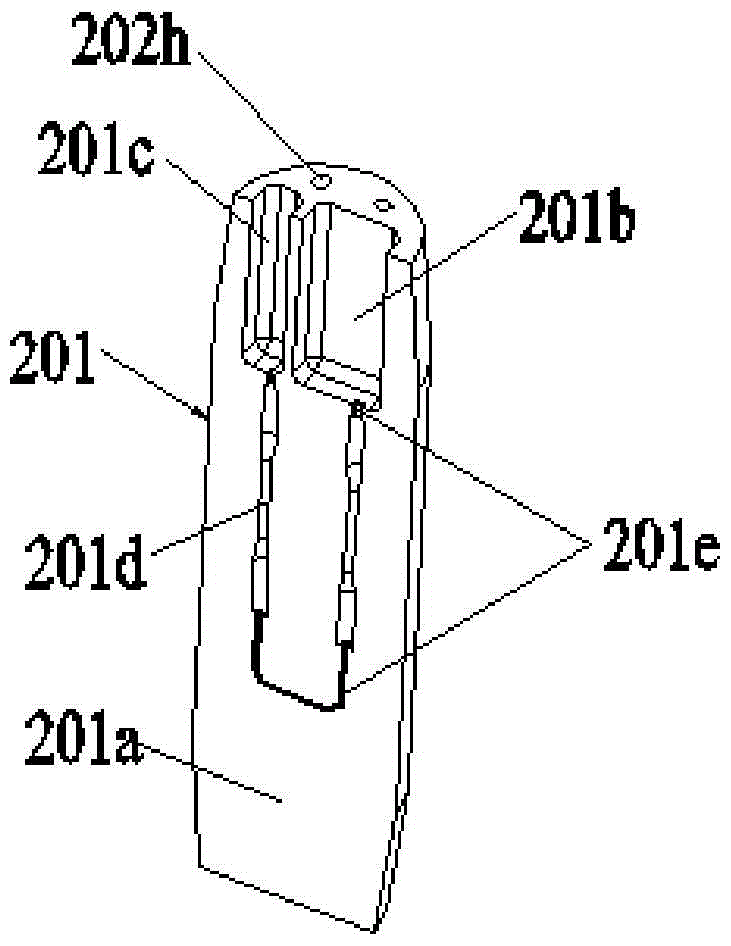

[0034] Embodiments of the present invention provide a system for casting alloys, such as figure 1 , figure 2 and image 3 , the system includes an ultrasonic device 1, a mold 2 and a heating device 3, the ultrasonic device 1 includes: a bracket 101, an ultrasonic generator 102 and an ultrasonic vibrator 103, the ultrasonic generator 102 is installed on the bracket 101, and one end of the ultrasonic vibrator 103 is connected to the ultrasonic The generator 102 is connected; the top surface of the mold 2 is provided with a gate 202f and a riser 202g, and the inside of the mold 2 is provided with a cavity and a runner 201e, and the cavity communicates with the gate 202f and the riser 202g respectively through the runner 201e , the other end of the ultrasonic vibrator 103 is located in the gate 202f or riser 202g, and the heating device 3 is arranged on the outer wall of the mold 2 . In this embodiment, the other end of the ultrasonic vibrator 103 is located in the gate 202f. ...

Embodiment 2

[0050] The embodiment of the present invention provides a method for processing castings using the system provided in Embodiment 1, such as Figure 6 As shown, the method includes:

[0051] Step 100: Combine Figure 1 to Figure 5 , spraying a release agent inside the mold 2;

[0052] Step 200: preheating the mold 2 through the heating device 3;

[0053] Step 300: Preheating the ultrasonic vibrator 103 into the gate 202f or riser 202g;

[0054] Step 400: Pour the alloy into the mold 2 through the gate 202f, and the alloy flows through the cavity through the gate 202f and emerges from the riser 202g;

[0055] Step 500: Vibrating the alloy through the ultrasonic vibrator 103;

[0056] Step 600: After the alloy is mixed evenly, remove the heating device 3, cool the mold 2, and the ultrasonic vibrator 103 continues to vibrate the alloy;

[0057] Step 700: before the alloy is solidified, stop the vibration, so that the ultrasonic vibrator 103 leaves the gate 202f or the riser 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com