Refined multifunctional welding system and control method thereof

A welding system and multi-functional technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

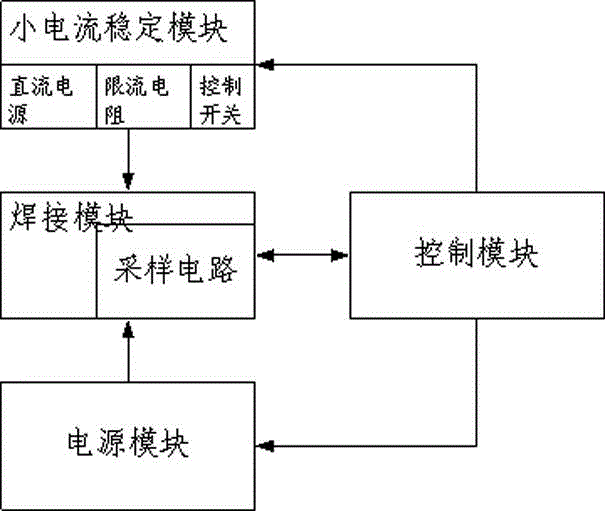

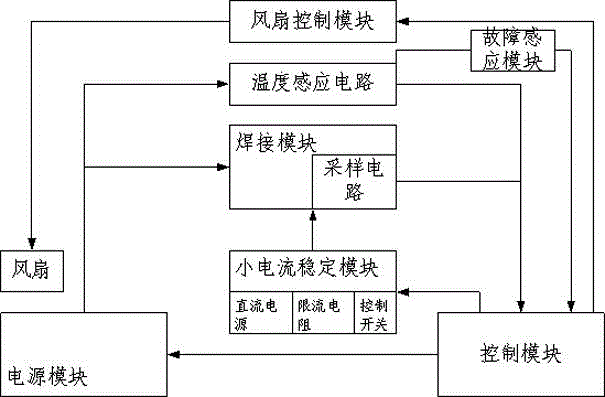

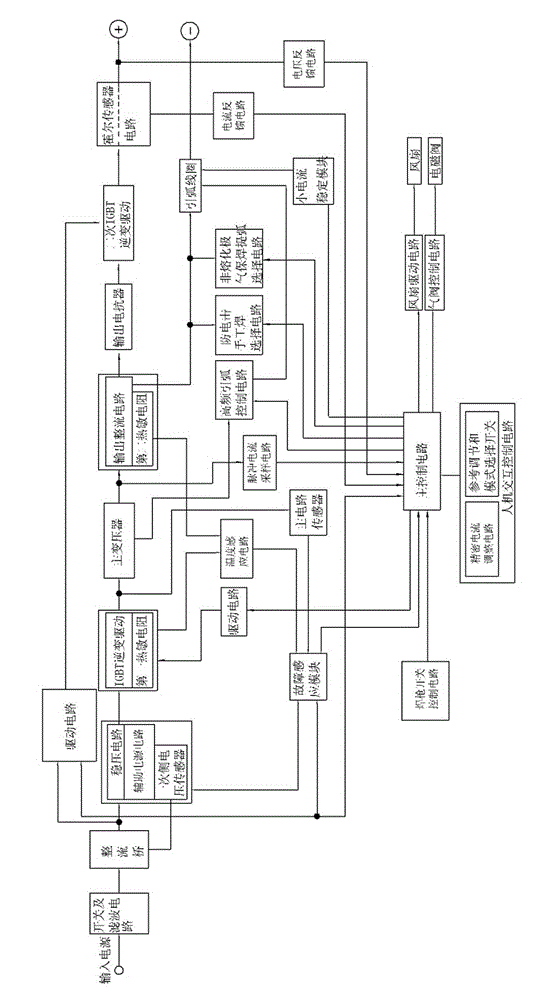

[0066] as attached Figure 1-3 As shown, a refined multifunctional welding system is provided with a welding module for performing welding; a sampling unit arranged on the welding module for sampling the welding current / voltage; electrically connected to the sampling unit and the welding module respectively, A power module used to provide power for the refined multifunctional welding system; it is also provided with a sampling unit and a power module electrically connected to store various welding characteristic parameters, and according to the characteristic parameters for the refined multifunctional welding system. A control module controlled by other modules; this control module can use the x86 microcomputer or single-chip microcomputer syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com