Apparatus and method for changing graphics and text on sheet-fed paper

A sheet-fed, graphic technology, applied to printing, printing devices, etc., can solve the problems of not meeting the real-time matching needs of the production line, troubles, etc., to achieve the effect of ensuring paper and improving printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

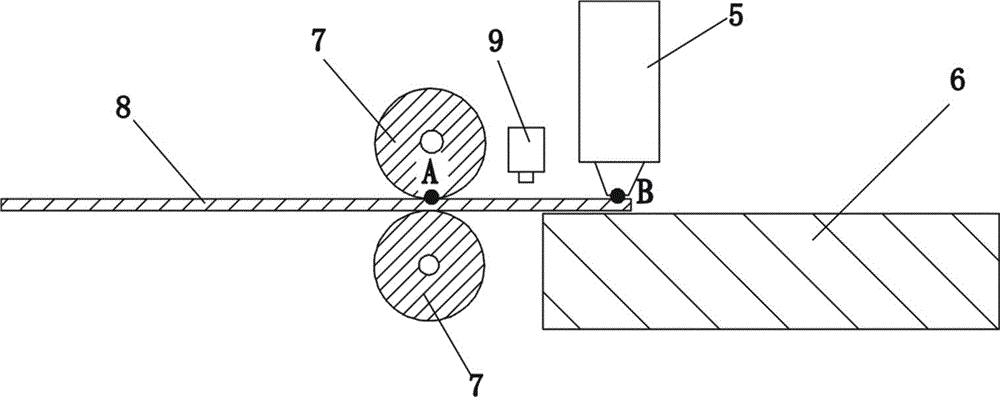

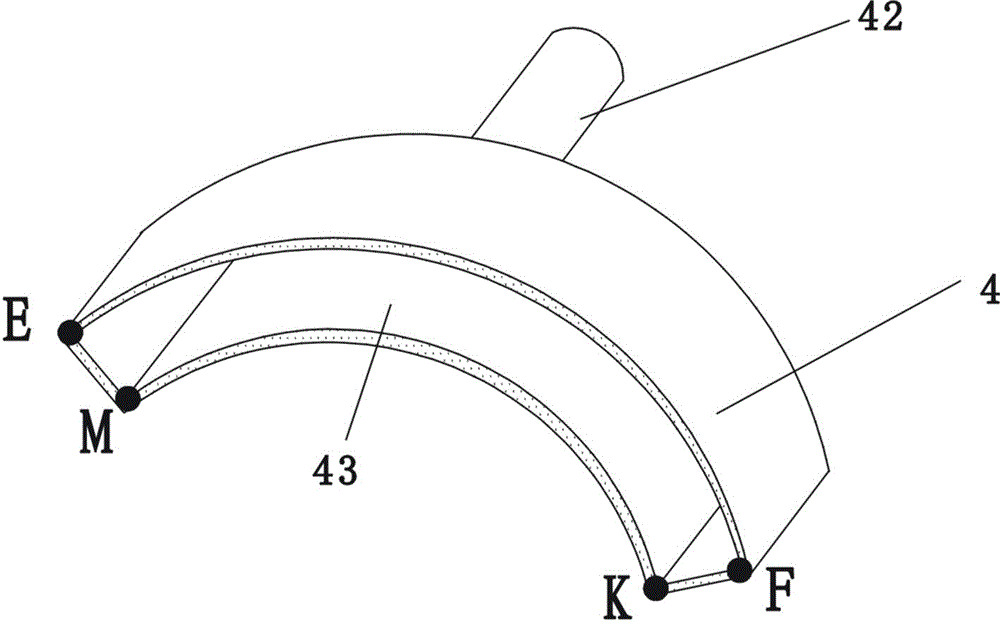

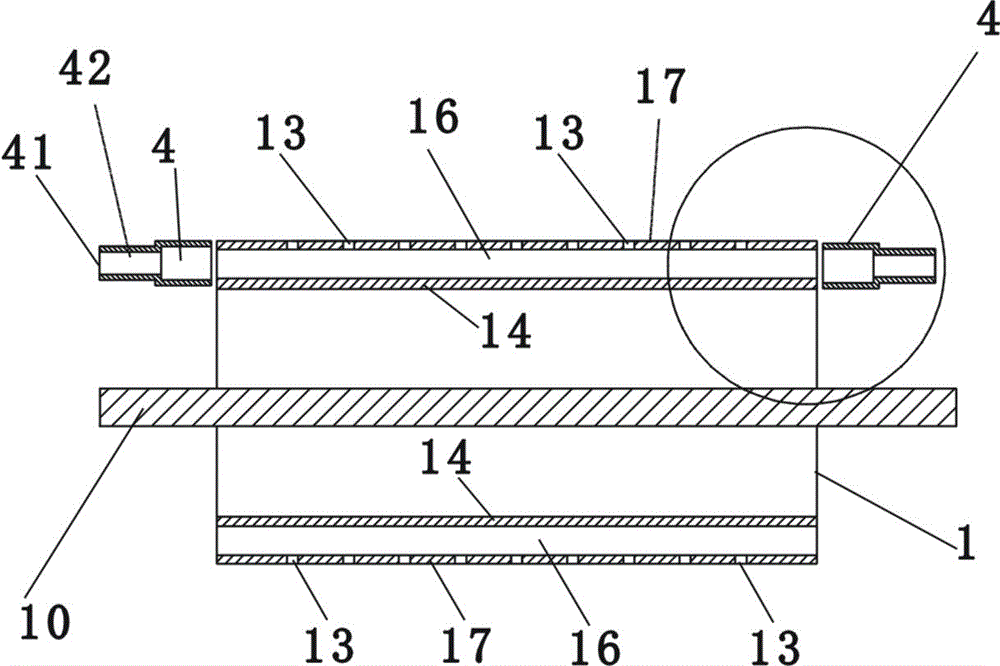

[0048] figure 2 , image 3 , Figure 8 , Figure 4 As shown, the sheet-fed changing graphics and text printing equipment includes an inkjet head 5 and a microprocessor. The microprocessor stores the data information of printing graphics and texts. Ink action, the inkjet head 5 is equipped with an ink cartridge 51, and a paper pad member is provided under the inkjet head 5. The paper pad member under the inkjet head is a circular roller 1 with a diameter equal to 80CM, and the circular roller 1 A rotating shaft 10 is provided, and the extension direction of the rotating shaft 10 is the front-to-back direction, the inkjet head 5 is close to the circumferential surface of the circular roller 1, and the ejection direction of the inkjet head 5 is the radial direction of the circular roller 1; A plurality of inkjet heads 5 are arranged in a circumferential arrangement, and the distance between each inkjet head 5 and the central axis of the circular roller is equal. The surface ...

Embodiment 2

[0054] A method for printing changing graphics and text on a sheet of paper, using the equipment for printing changing graphics and text on a sheet of paper according to Embodiment 1, comprising the following steps:

[0055] (1), input the data information of the paper 8 to be printed into the microprocessor; the external air pumping part continuously pumps air from the main air pumping hole 41, so that the arc negative pressure chamber 4 maintains negative pressure, and then makes the arc shape Each elongated chamber 16 of the circular roller aligned with the middle section of the arc-shaped opening 43 of the negative pressure chamber 4 continuously forms a stable negative pressure;

[0056](2) The circular paper transfer part (circular paper transfer sprocket 2) of the paper transfer mechanism is constantly rotating, and the paper transfer chain 22 is driven by the circular paper transfer sprocket 2. The paper bite 21 bites the front edge of the paper 8 and drives the paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com