Large high-temperature high-lift two-stage full-lining oil slurry pump

A high-lift, lining technology, used in pumps, pump components, non-displacement pumps, etc., can solve problems such as increasing the internal stress of the pump body, leakage, and damage to the pump body, and achieve the effect of preventing damage and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] For ease of understanding, the specific structure of each component in the headlight module will be further described below in conjunction with the accompanying drawings.

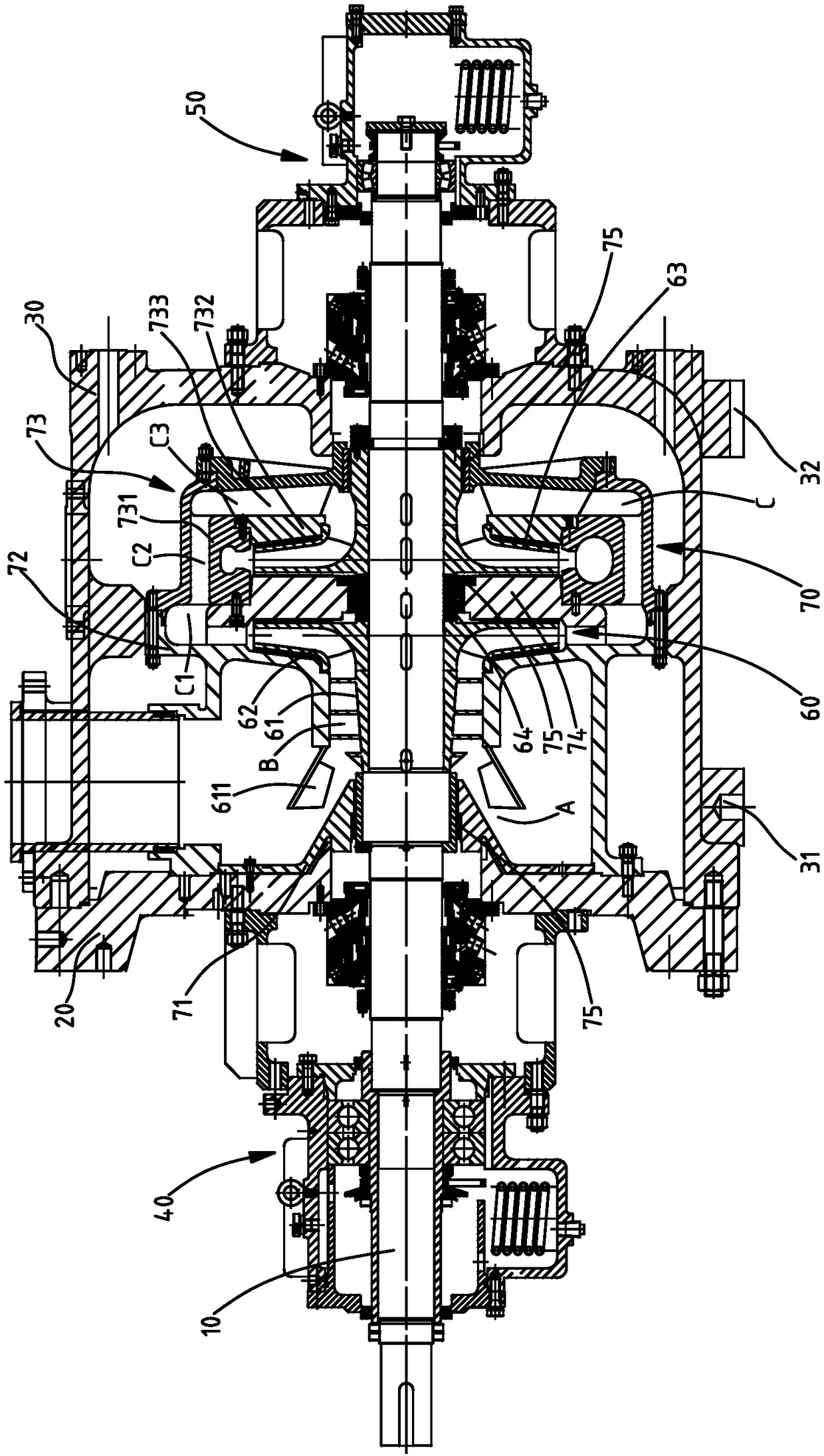

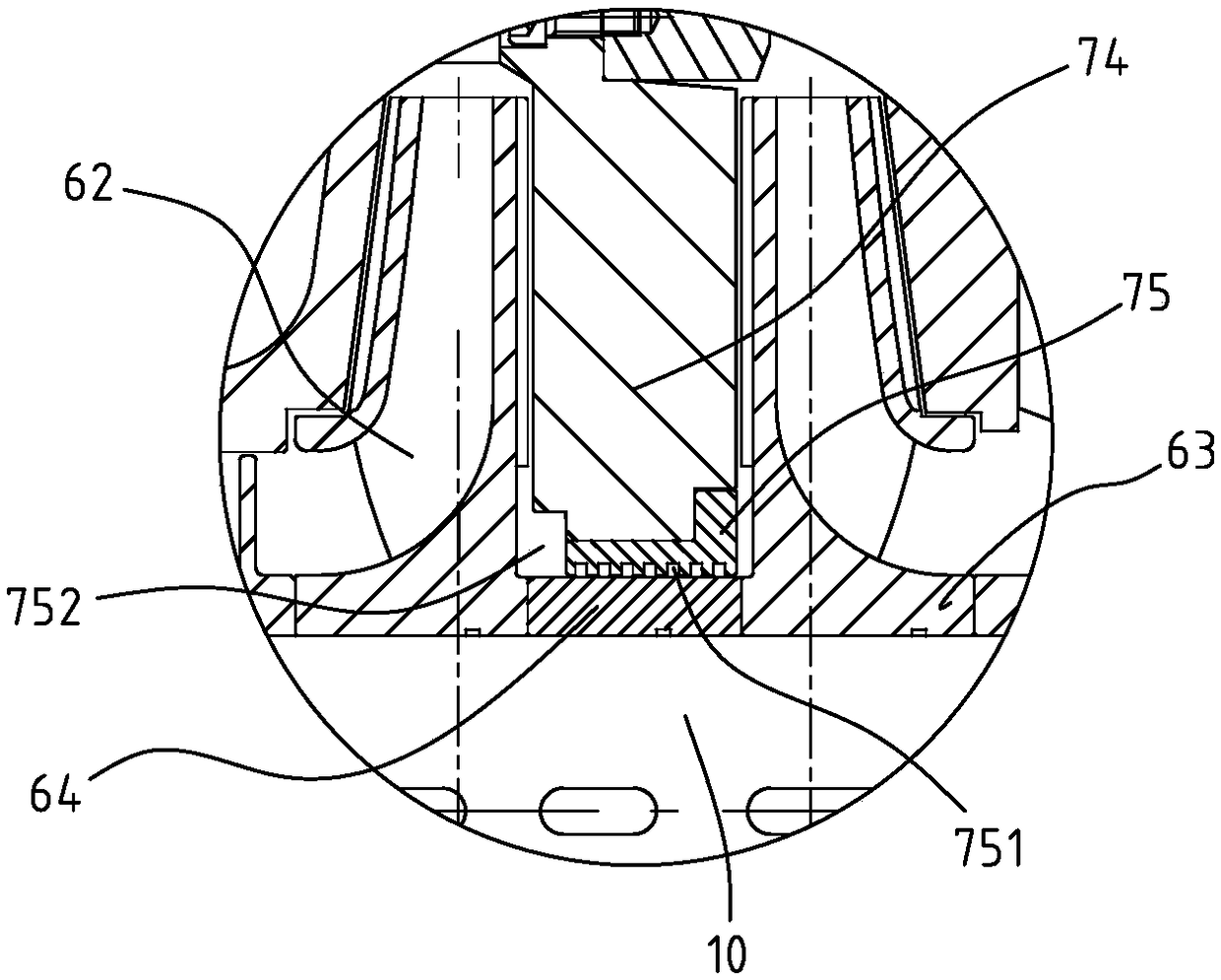

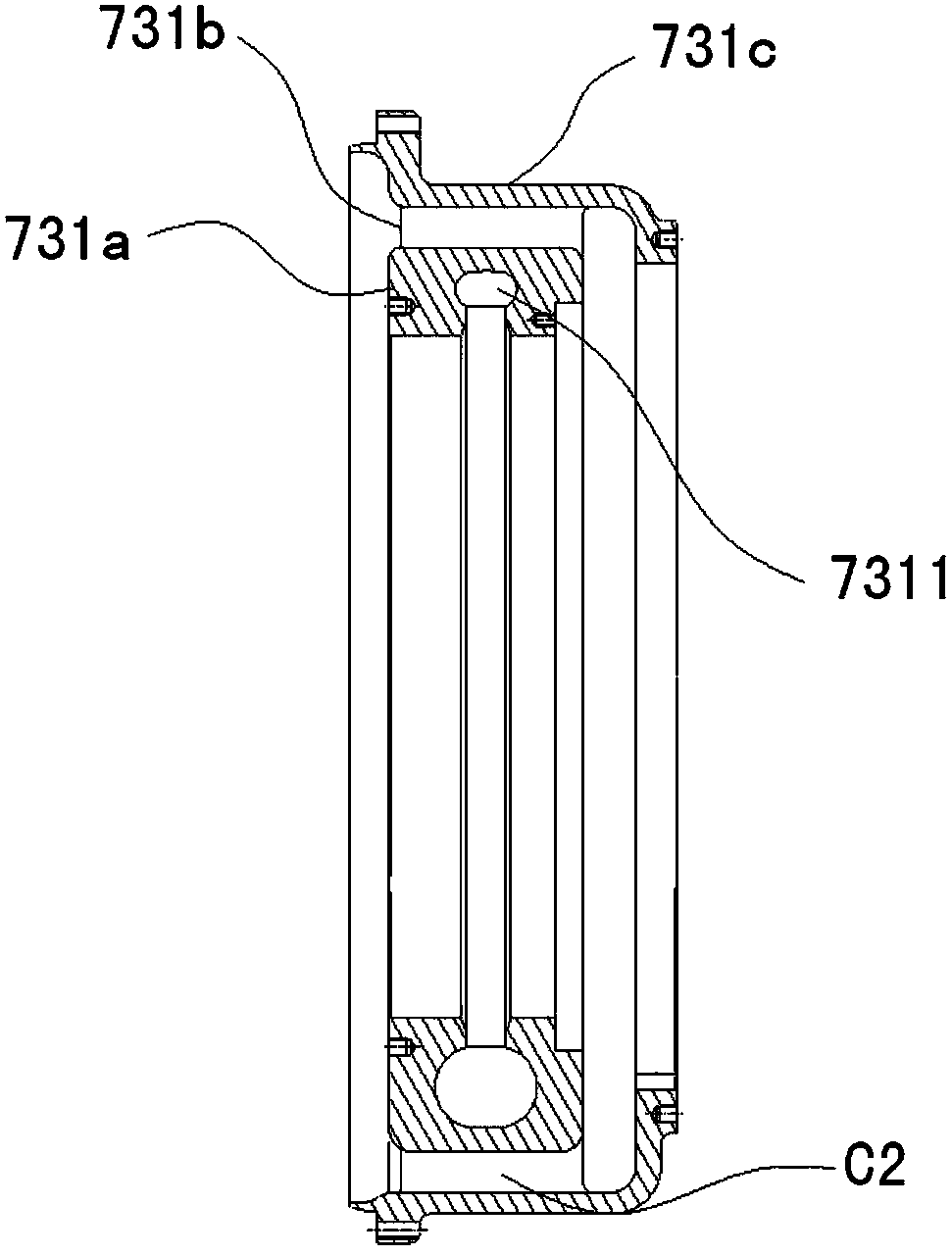

[0042] Such asfigure 1 , 2 As shown, a large-scale high-temperature, high-lift two-stage fully lined slurry pump includes a shaft 10, and a pump cover 20 fixed on the shaft 10 and an outer casing 30, and the pump cover 20 and the outer casing 30 are fixed to each other and together form a housing cavity, the end of the housing 30 close to the driving side is provided with a positioning pin hole 31, and the positioning pin hole 31 is provided with a positioning pin matched with the base; One end on the driving side is provided with a guide structure.

[0043] Such as figure 1 As shown, the outer casing 30 is placed on the base; the guide structure includes a guide groove 32 provided on the outer casing 30 , and the outer casing 30 can slide and fit with the base through the guide groove 32 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com