A preparation method of an all-steel radial tire reinforced with a steel wire-wrapped composite part

A technology of radial tires and composite parts, applied in tire parts, tires, tire edges, etc., can solve the problems of weak ladle reinforcement, high technical requirements, difficult positioning, etc., to prevent stress concentration and improve safety performance. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the patent according to the present invention will be described in detail as follows.

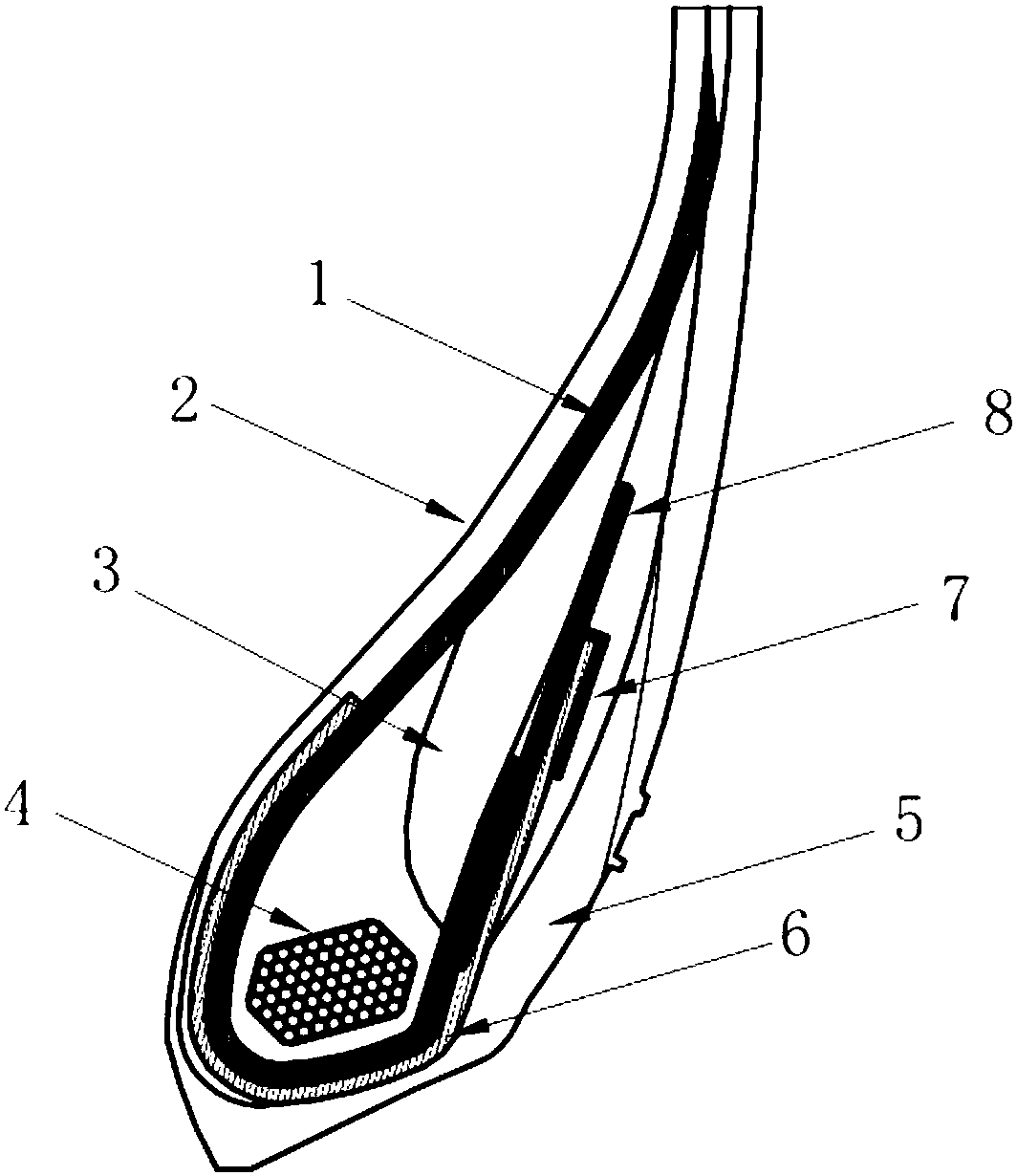

[0030] An all-steel radial tire with a bead reinforced with steel wire cloth, the structure of which includes a crown, a tire shoulder, a carcass ply (1), an inner liner (2), a belt layer, a steel wire cloth composite part and a tire lock up. Such as figure 1 As shown, the carcass ply (1) turns up the traveler (4), and the inner side of the steel wire cloth (6) fits between the carcass ply (1) and the inner liner (2), and the inner end point is slightly lower At the turn-up end point of the carcass ply (1); the outer side of the steel wire cloth (6) is attached between the carcass ply (1) and the wear-resistant rubber (5), and on the outer side of the steel wire cloth (6) Glue wrapping is performed at the edge of the turn-up and a layer of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap