Hydrostatic pressure release device

A hydrostatic pressure release device technology, applied in the field of automatic underwater release devices, can solve the problems of hidden safety hazards, complex structure, low assembly efficiency, etc., and achieve the effect of ensuring normal use, safety during transportation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

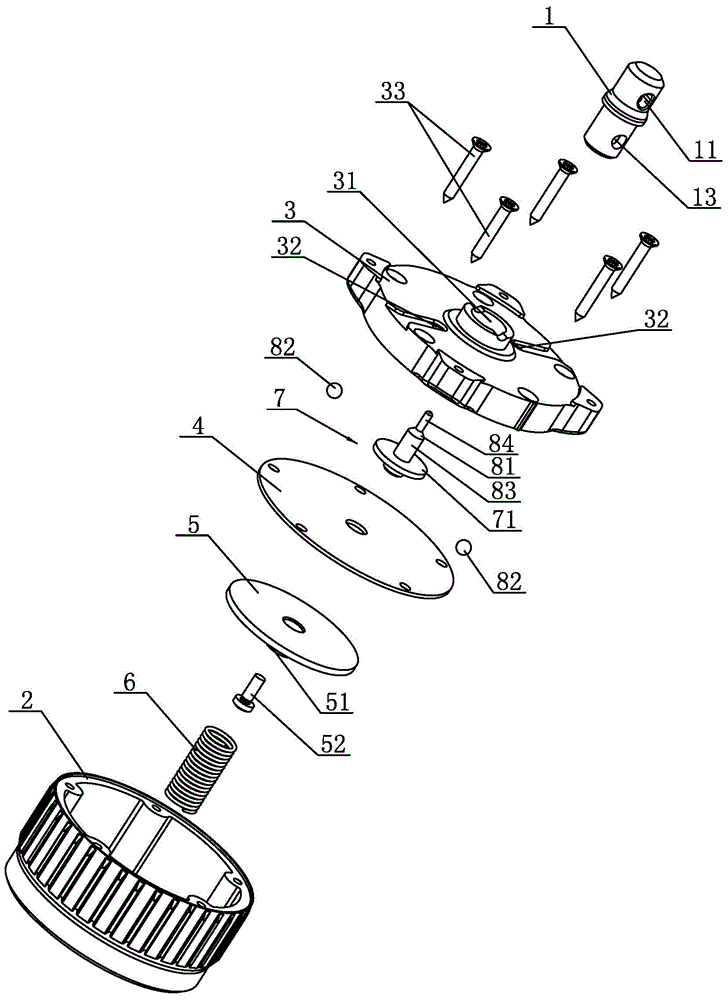

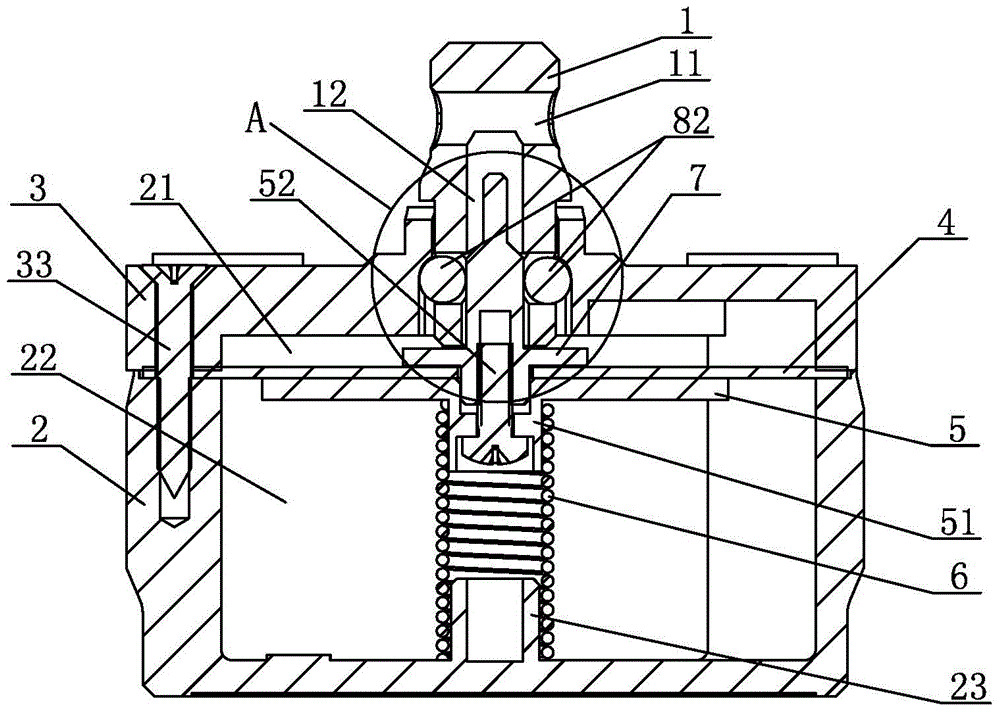

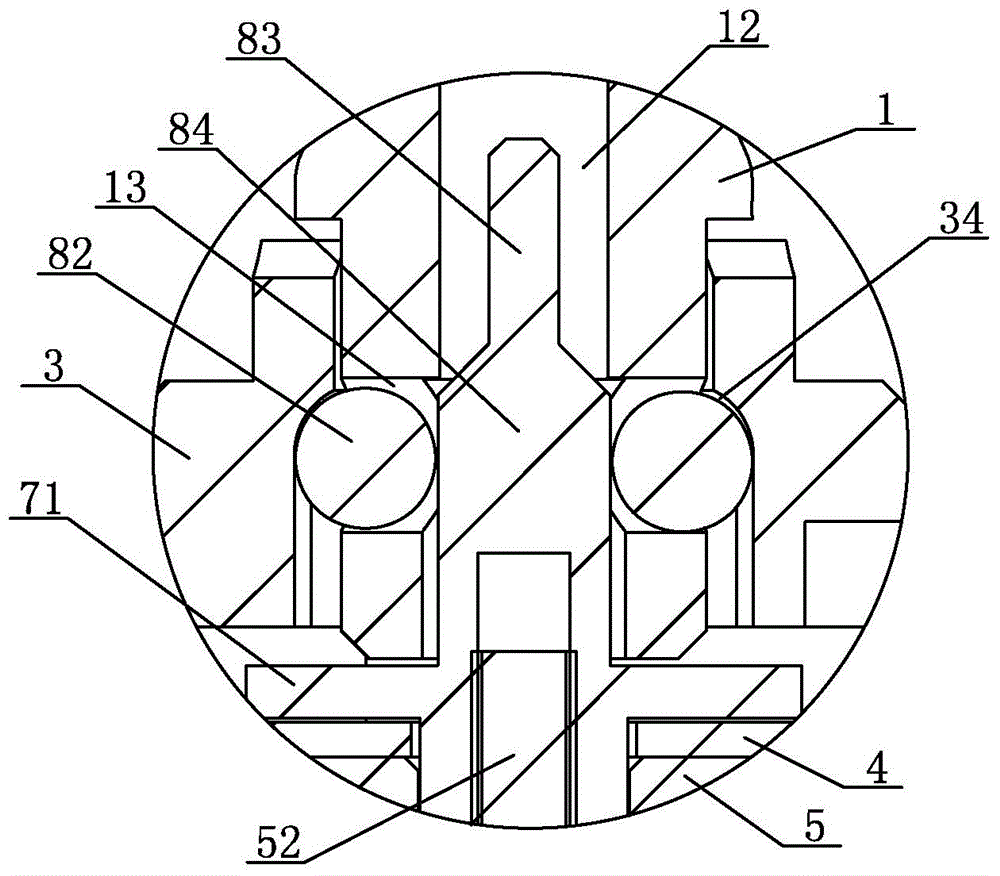

[0016] The hydrostatic pressure release device of the embodiment, as shown in the figure, includes a core rod 1, a base 2 and an end cover 3, the end cover 3 is fixed on the upper part of the base 2, and the end cover 3 is provided with a mounting hole 31 and two symmetrically arranged The water inlet hole 32, the upper end of the core rod 1 is provided with a connection hole 11 for connecting the device to be released (not shown in the figure), the base 2 and the end cover 3 form a chamber, and the end cover 3 and the base 2 are fixed There is a rubber membrane 4, the end cover 3, the rubber membrane 4 and the base 2 are fixedly connected by five second connecting screws 33, the rubber membrane 4 divides the chamber into an upper chamber 21 and a lower chamber 22, and the lower part of the rubber membrane 4 is set There is a pressing plate 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com