A multi-mode hoist and its working method

A hoist, multi-mode technology, used in conveyors, storage devices, transportation and packaging, etc., can solve the problems of inflexible transportation, low efficiency, single hoist mode, etc., and achieve ingenious design, flexible transportation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

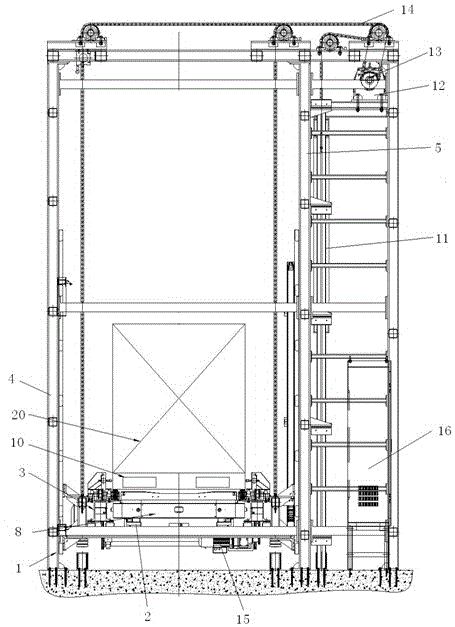

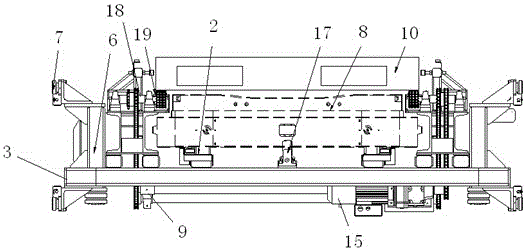

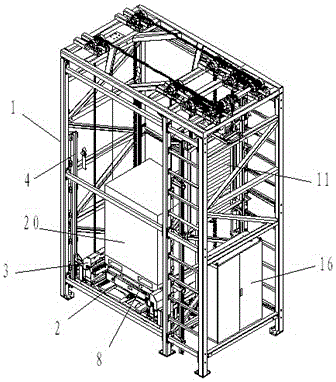

[0018] Embodiment of the present invention: a multi-mode hoist, including a frame 1, a shuttle plate guide rail 2 and a cargo platform 3 are arranged at the bottom of the frame 1, and limit rails are respectively arranged on the columns on both sides of the frame 1 4 and the counterweight track 5, the cargo platform 3 includes a cargo platform frame 6, on the cargo platform frame 6 is provided with a lifting limit wheel 7 that can slide in the limit rail 4, on the cargo platform frame 6 is provided with a shuttle board 8 that can slide on the shuttle board guide rail 2, and two mutually symmetrical chain conveyors 9 are arranged on the cargo platform frame 6, and a pallet 10 is provided on the shuttle board 8; 1 is provided with a driving device, and a counterweight 11 is provided on the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com