Winding device for clean ball hydrangea machine

A technology of winding device and cleaning ball, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of insufficient elasticity and insufficient elasticity, and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

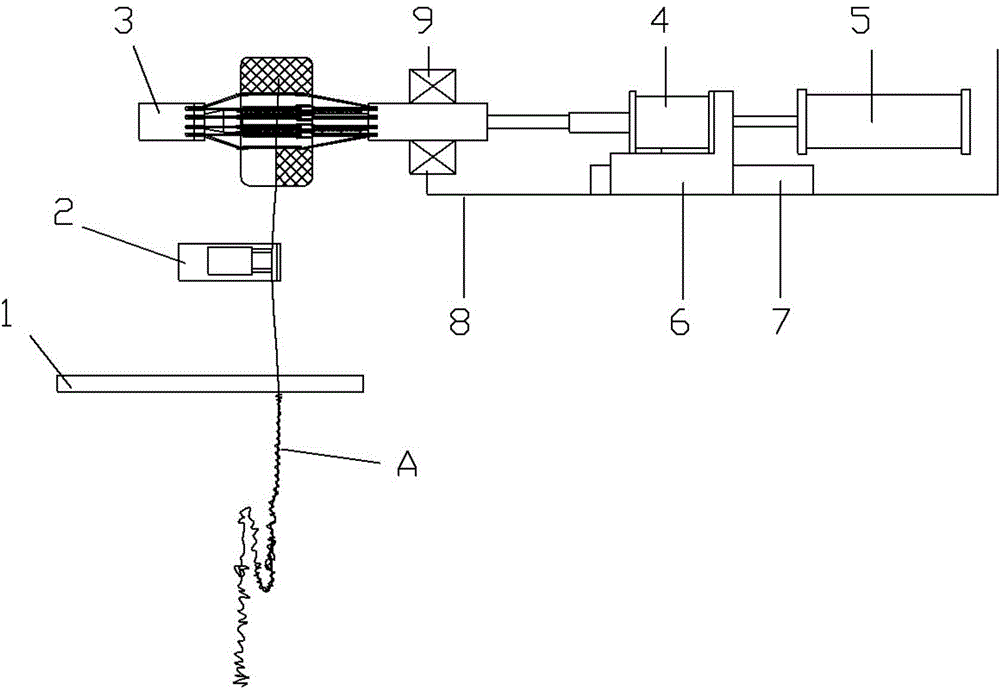

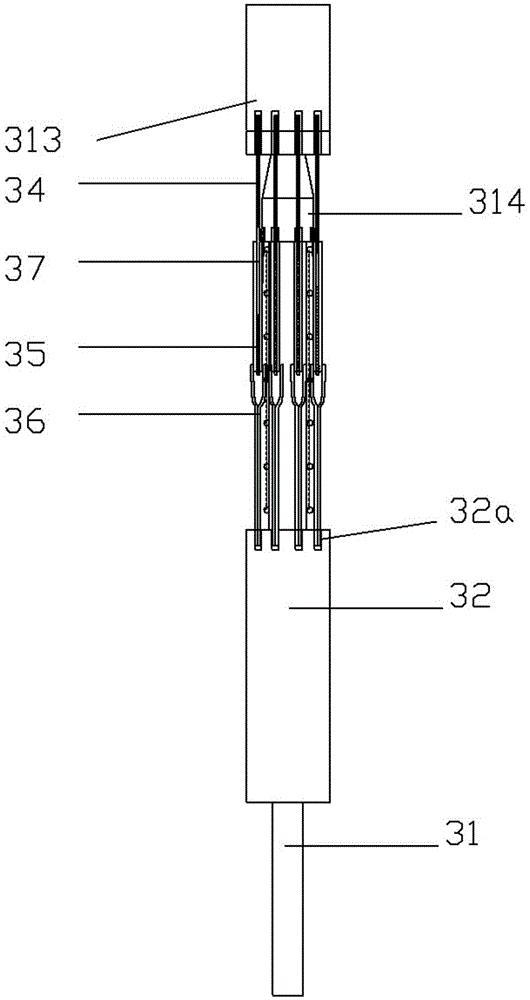

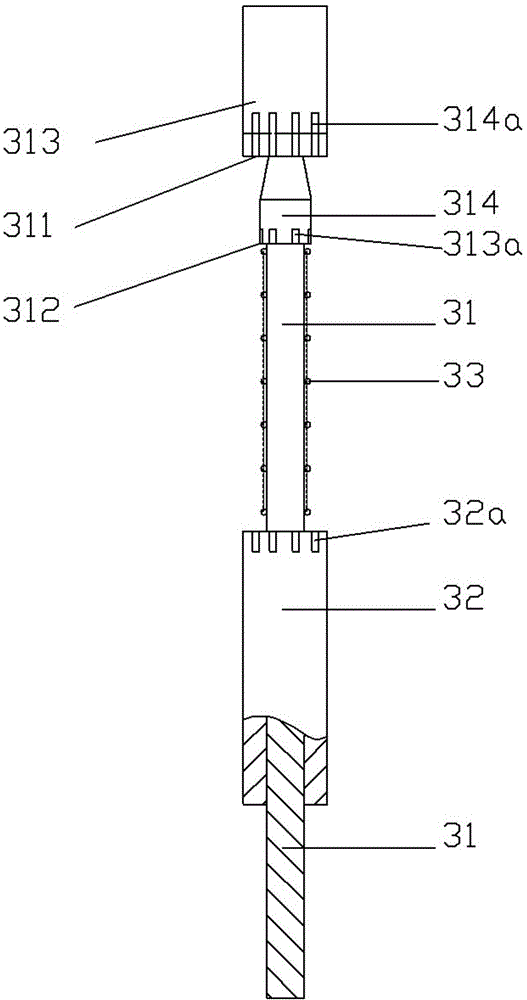

[0018] Example: see Figures 1 to 6 As shown, the winding device for the cleaning ball hydrangea machine includes a traverse rod 1, a thread cutter 2 and a winding motor 4. The structure of the winding shaft 3 is that the main shaft 31 is inserted into the shaft seat 32, and the shaft seat 32 is fixed on the machine. On the frame 4, a first step 311 and a second step 312 are sequentially formed from top to bottom on the main shaft 31. The top of the first step 311 is a big head post 313, and the top of the second step 312 is a small head post 314. The big head column hinge groove 313a, the small head column hinge groove 314a and the axle seat hinge groove 32a respectively formed on the head column 314 and the shaft seat 32, the upper end of the first connecting rod 34 is placed in the big head column hinge groove 313 and hinged on the big head column. 313, the lower end of the first connecting rod 34 is hinged with the second connecting rod 35, the lower end of the second conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com